Resistance high-precision measuring system and method with combination of differential method and proportion method

A proportional method and resistance technology, which is applied in the field of low-cost high-precision resistance measurement systems, can solve the problems of difficulty in high-precision resistance measurement, reduce the cost of measurement systems, and cannot be obtained. The effect of reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

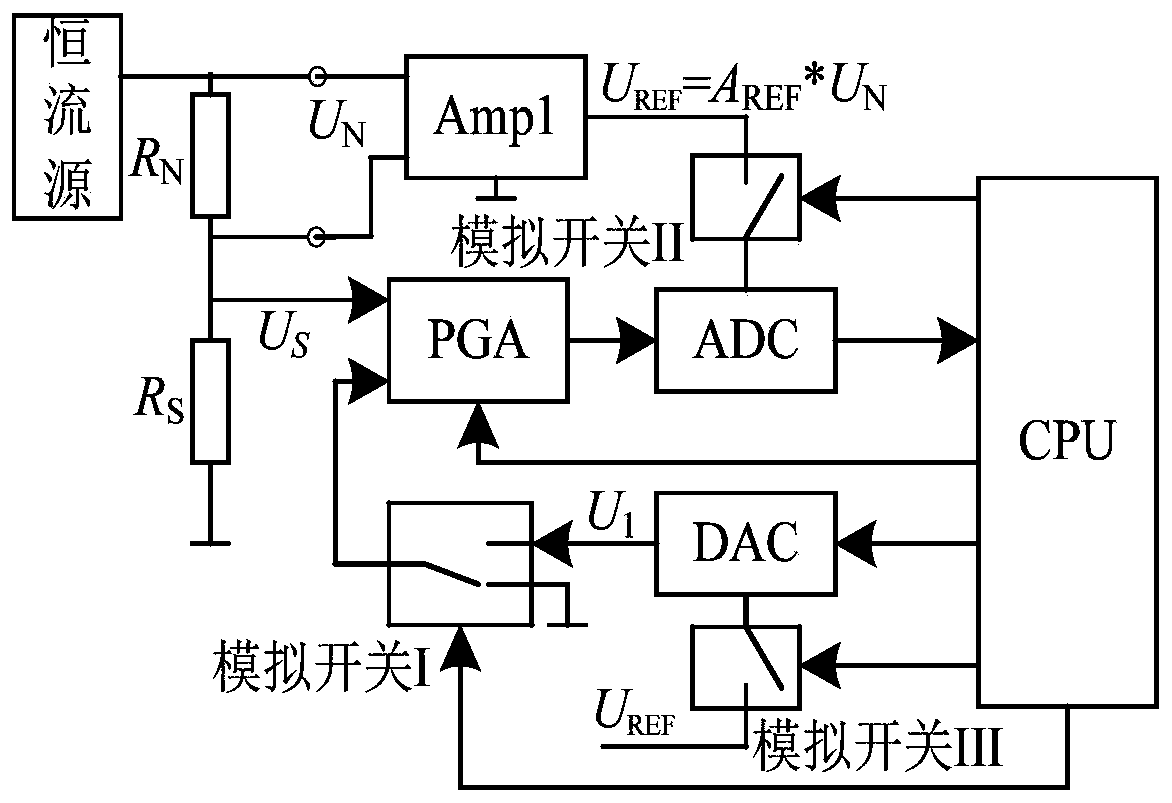

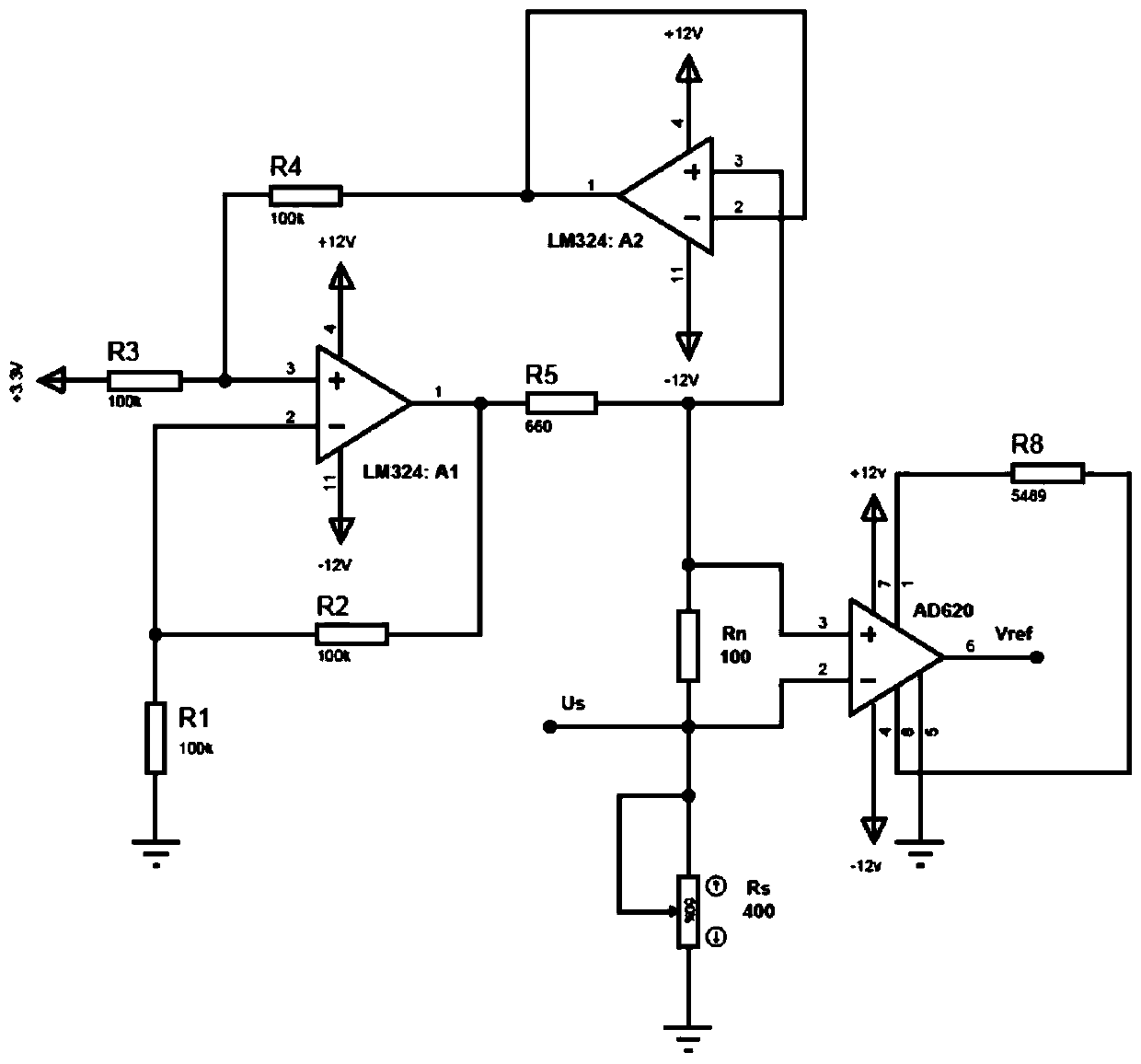

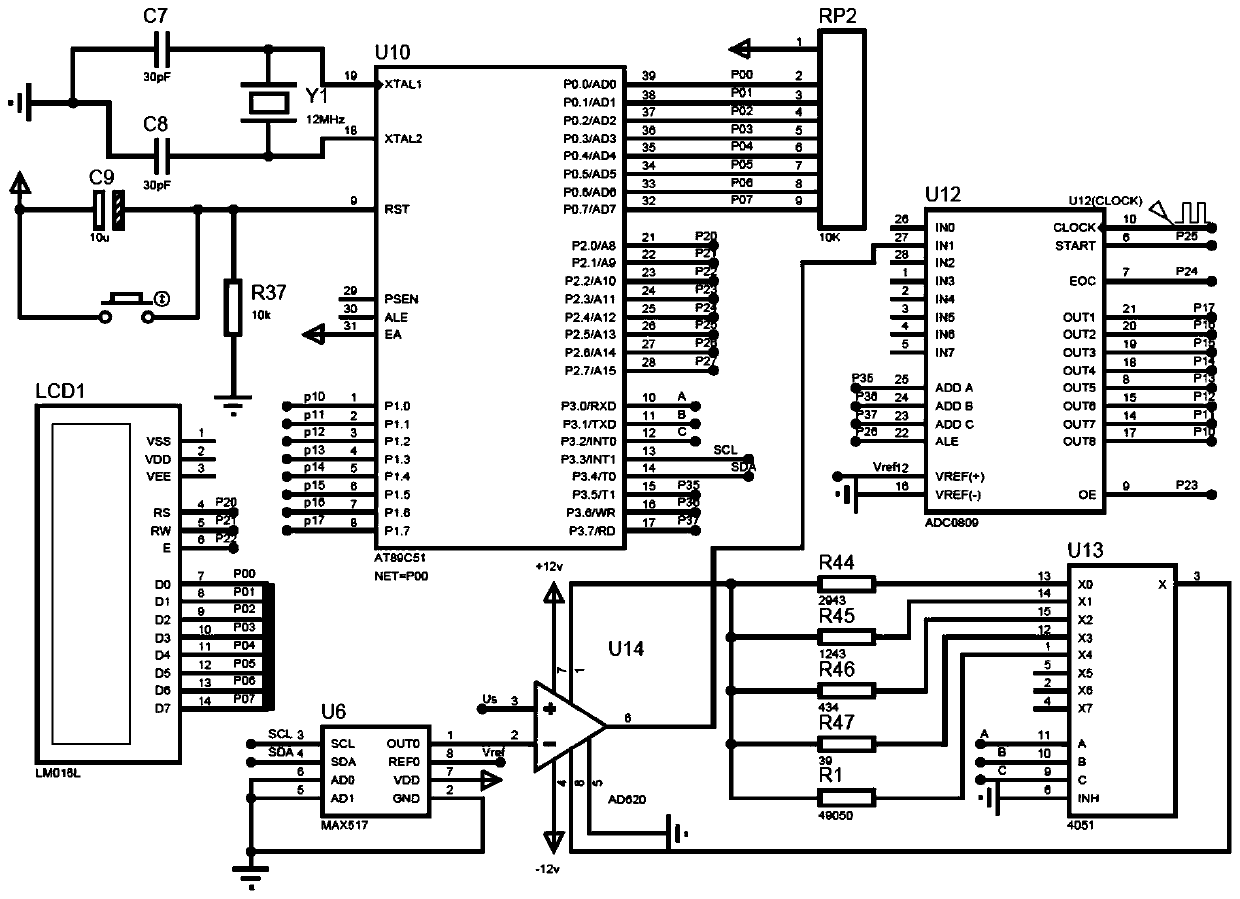

[0053] This embodiment provides a resistance measurement system combining the differential method and the proportional method, and its principle block diagram is as follows figure 1 As shown, the specific circuit diagram is shown in image 3 As shown, including the measured resistance interface, constant current source, reference resistance R N , a first differential amplifier Amp1, a programmable gain amplifier PGA, an analog-to-digital converter ADC, a microprocessor CPU, a digital-to-analog converter DAC, a first analog switch I, a second analog switch II and a third analog switch III.

[0054] The first end of the reference resistor is connected to the first end of the interface of the measured resistance, the second end of the reference resistor is connected to the constant current source, and the second end of the interface of the measured resistance is grounded.

[0055] The two ends of the reference resistor are respectively connected to the two input terminals of the...

Embodiment 2

[0084] In Embodiment 1, since one end of the resistance under test is grounded, the voltage at the common connection end of the resistance under test and the reference resistance, that is, the single-ended voltage to ground corresponding to the potential difference between the two ends of the resistance under test, can be directly input to The first input terminal of the programmable gain amplifier. In the second embodiment, the difference from the first embodiment is that in this embodiment, the interface of the reference resistance and the measured resistance is exchanged, and a second differential amplifier is set between the measured resistance and the programmable gain amplifier, such as Figure 4 shown. In the second embodiment, since both ends of the measured resistance have potentials, it is necessary to set a second differential amplifier Amp-2 with a gain of one time between the measured resistance and the first input terminal of the programmable gain amplifier. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com