Peach slice powder screening machine

A technology of sifting machine and peach slices, which is applied in baking, baked food, dough processing, etc., can solve problems such as manual sifting, and achieve the effects of low labor intensity, high product quality, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment the present invention will be further described.

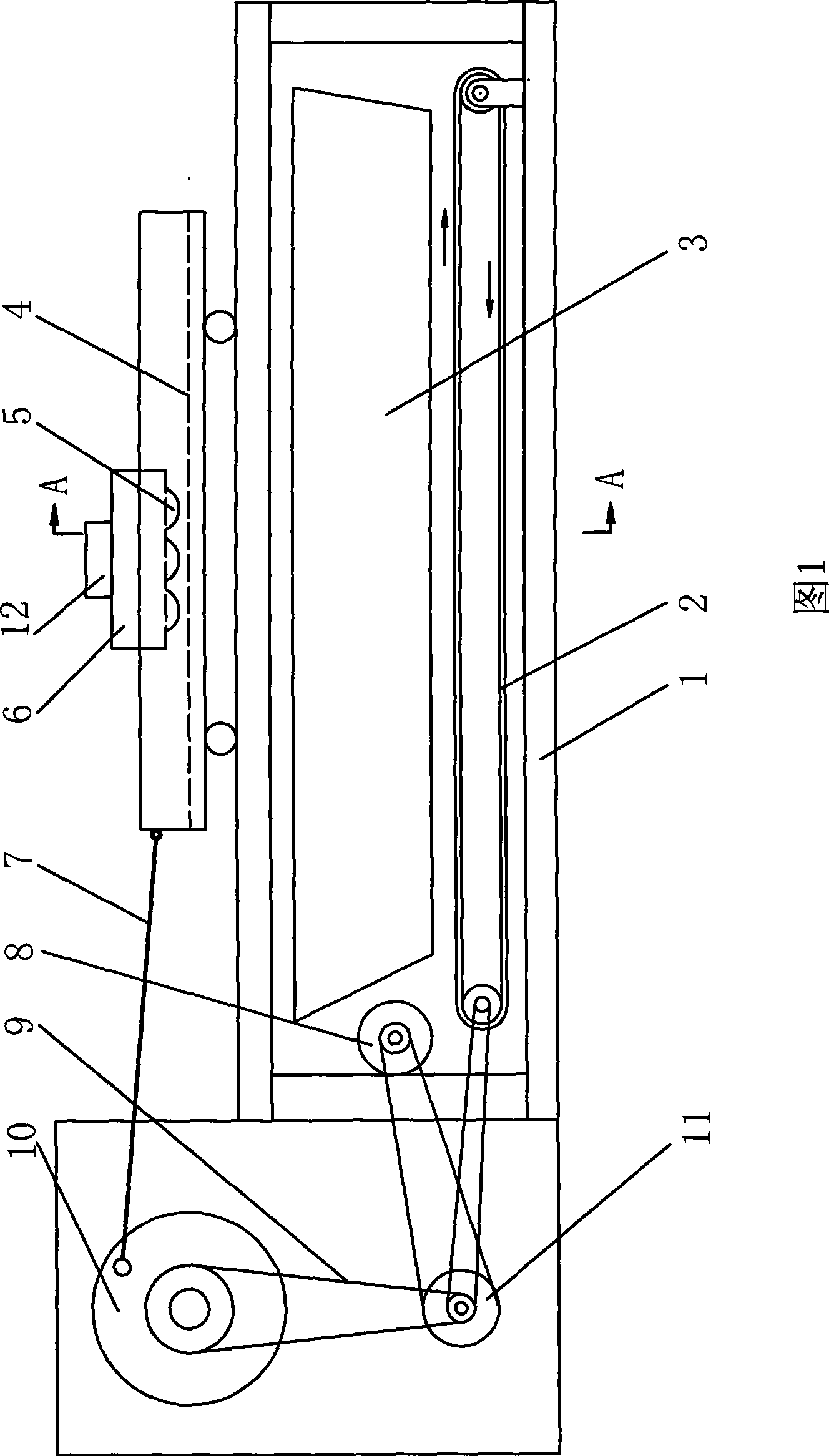

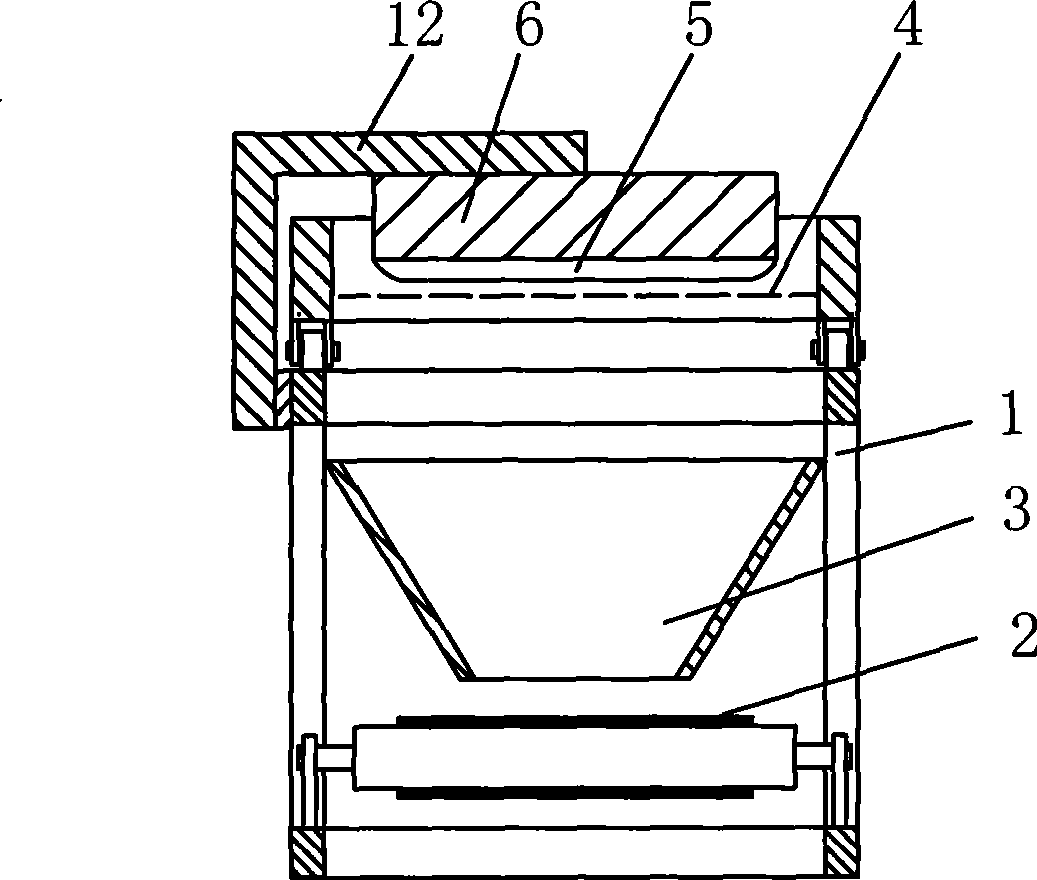

[0015] Figure 1, figure 2 Shown, a kind of peach powder sieve machine, comprises motor 8, sieve 4, belt 9, is provided with eccentric wheel 10 at the machine head of frame 1, and eccentric wheel 10 is connected with sieve 4 through connecting rod 7, is located at frame 1. The motor 8 at the lower part rotates the eccentric wheel 10 through the pulley 11 and the belt 9. The eccentric wheel 10 drives the sieve 4 to reciprocate through the connecting rod 7. A friction plate 6 is provided above the sieve 4, and a funnel is provided below the sieve 4. 3. A transmission belt 2 is provided below the funnel 3, and the transmission belt 2 is driven by the motor 8 through the pulley 11 and the belt 9. The friction surface of the friction pressing plate 6 is a corrugated friction surface 5, and the distance between the corrugated friction surface 5 of the friction pressing plate 6 and the sieve 4 is 10 mm. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com