Miniature self-service ground robot

A robot and ground technology, applied in the direction of manipulators, motor vehicles, chucks, etc., can solve the problems of complex control, inconvenient operation and transfer, and blank special robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

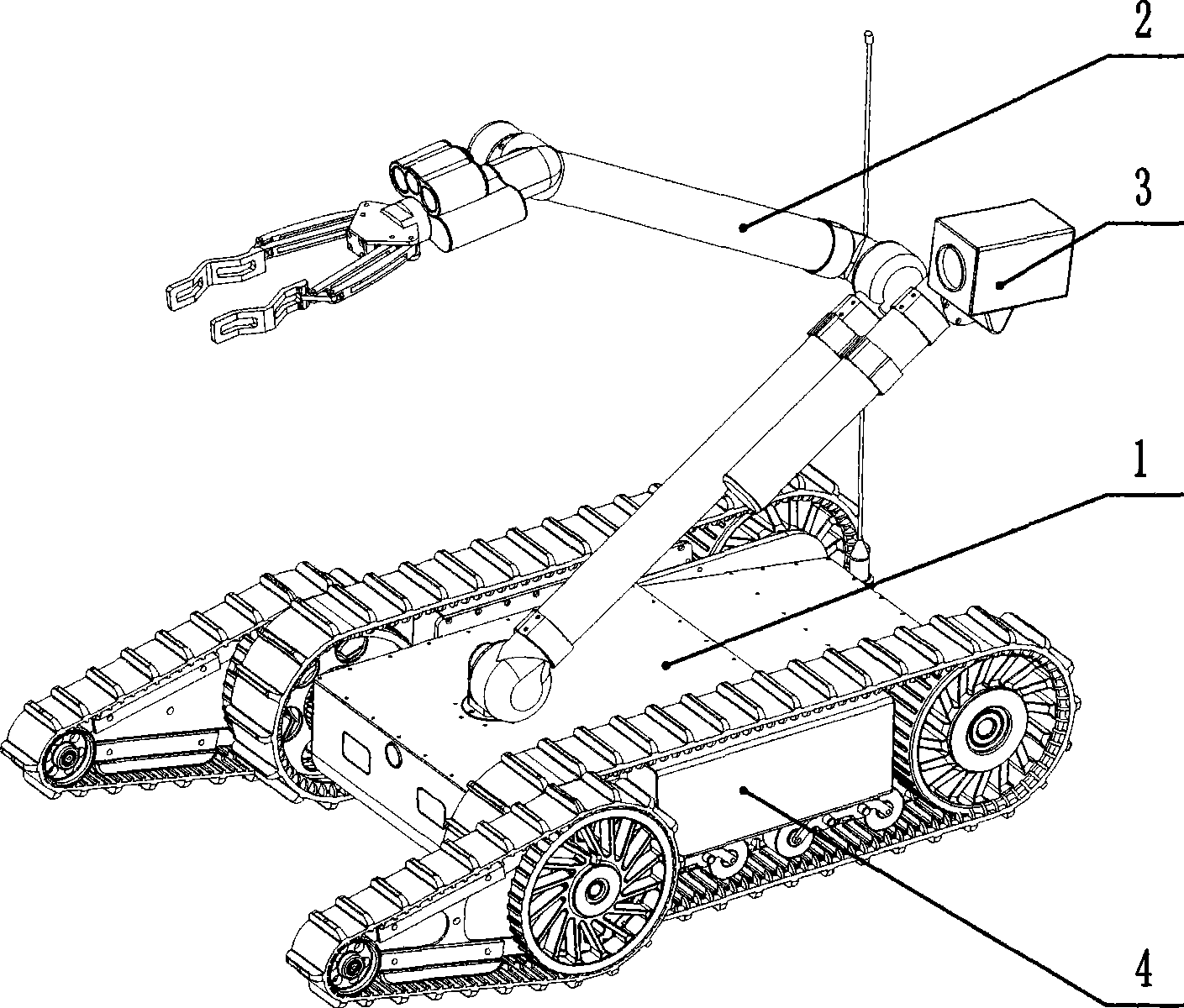

[0027] The invention provides a small unmanned ground robot, which is characterized in that: the small unmanned ground robot includes a drive travel mechanism 1, an arm mechanism 2, a camera pan-tilt part 3, a robot chassis frame 4, a control module 5 and a robot is a split structure;

[0028] The driving traveling mechanism 1 is fixedly installed on the robot chassis frame 4, the arm mechanism 2 is installed on the driving traveling mechanism 1 in a detachable manner, the camera pan-tilt part 3 is installed on the arm mechanism 2 in a detachable manner, and the control module 5 is installed on the Robot chassis frame 4 inside.

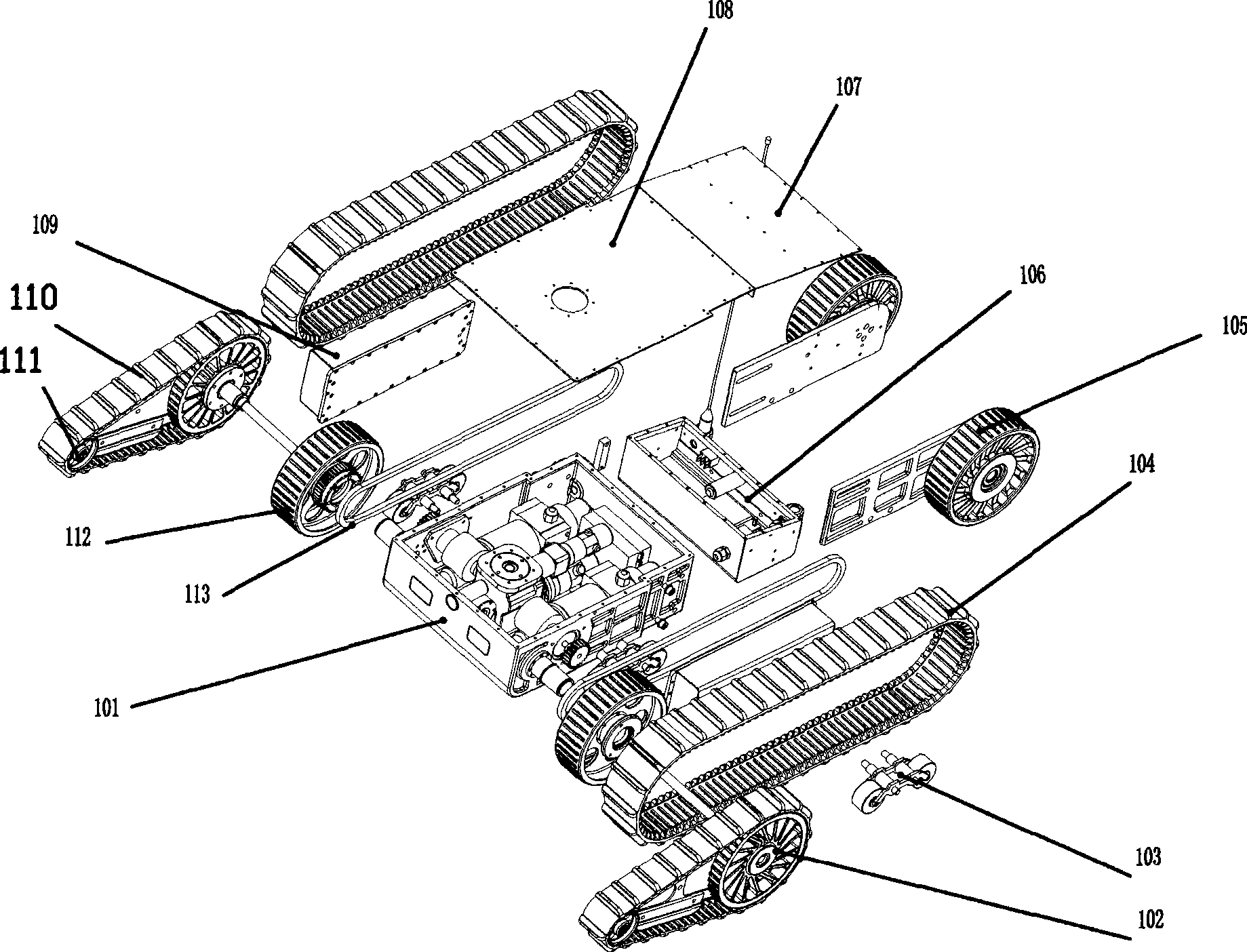

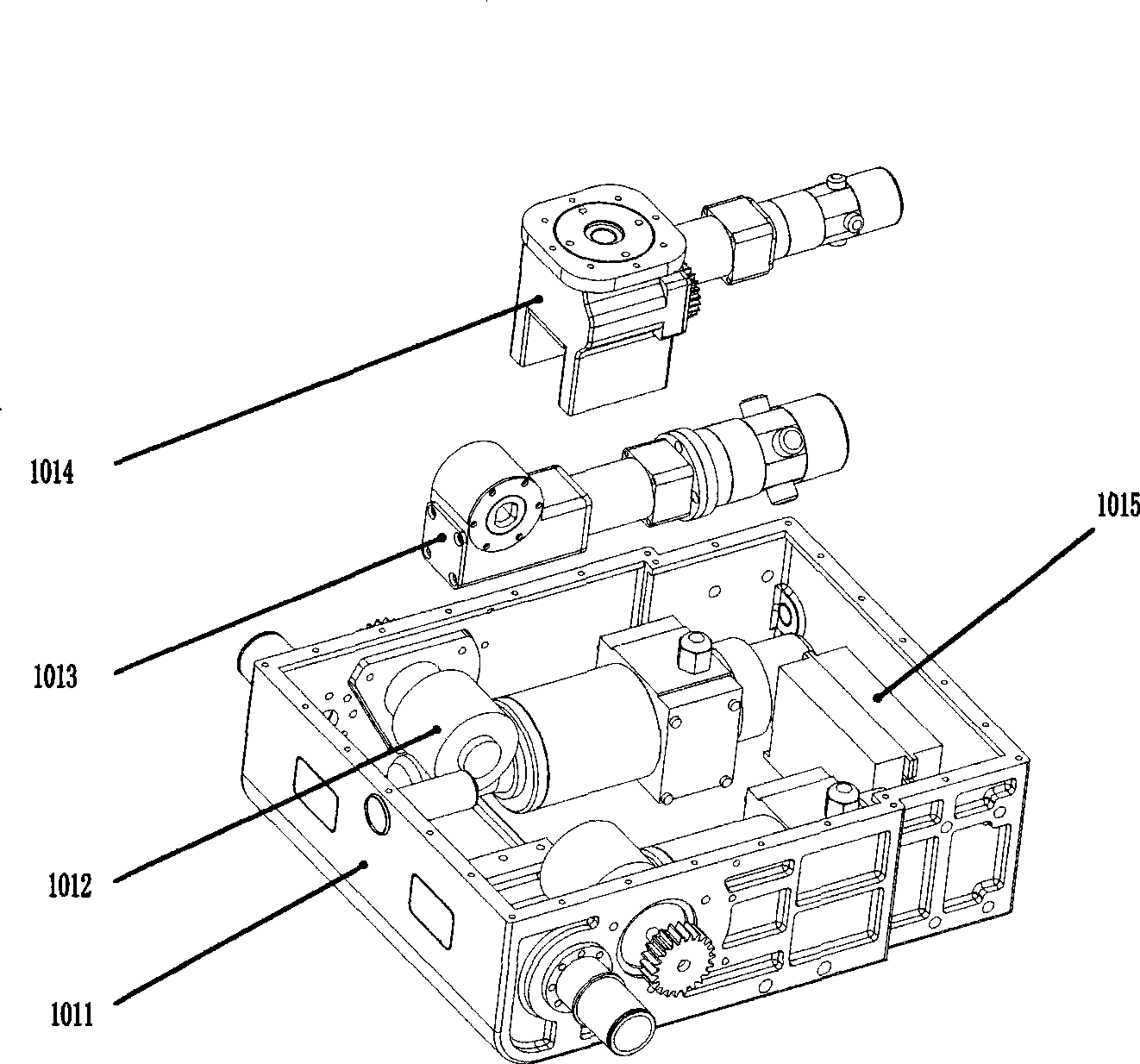

[0029] Described driving traveling mechanism 1 comprises front box body 101, front auxiliary wheel 102, crawler belt tensioner 103, travel crawler belt 104, rear wheel 105, rear box body 106, rear box cover 107, front box cover 108, battery box 109 , auxiliary crawler 110, small front wheel 111, driving wheel 112, chain 113; driving wheel 112 and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com