Fan filter screen unit and dust-free chamber

A fan filter and clean room technology, applied in the direction of pump components, ventilation systems, dispersed particle filtration, etc., can solve the problems of small fan filter unit coverage, short cycle dust particles, retention, etc., to reduce construction costs Effects on energy consumption, reduction of uneven cleanliness, and increase in circulating air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

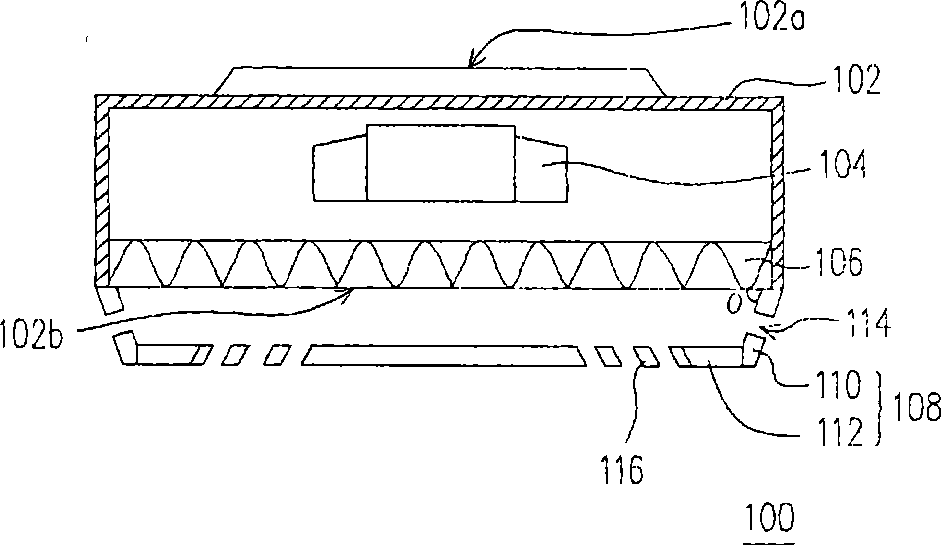

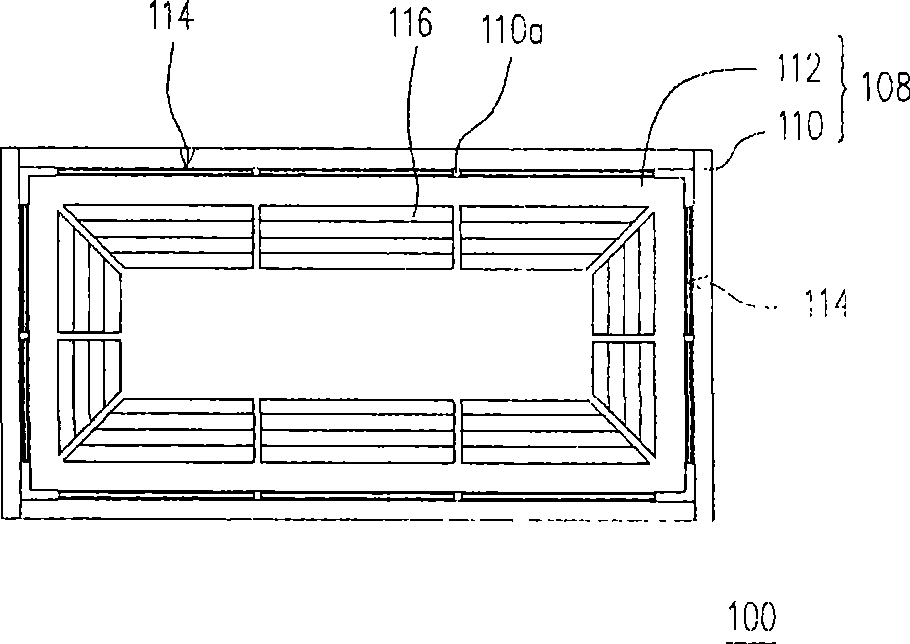

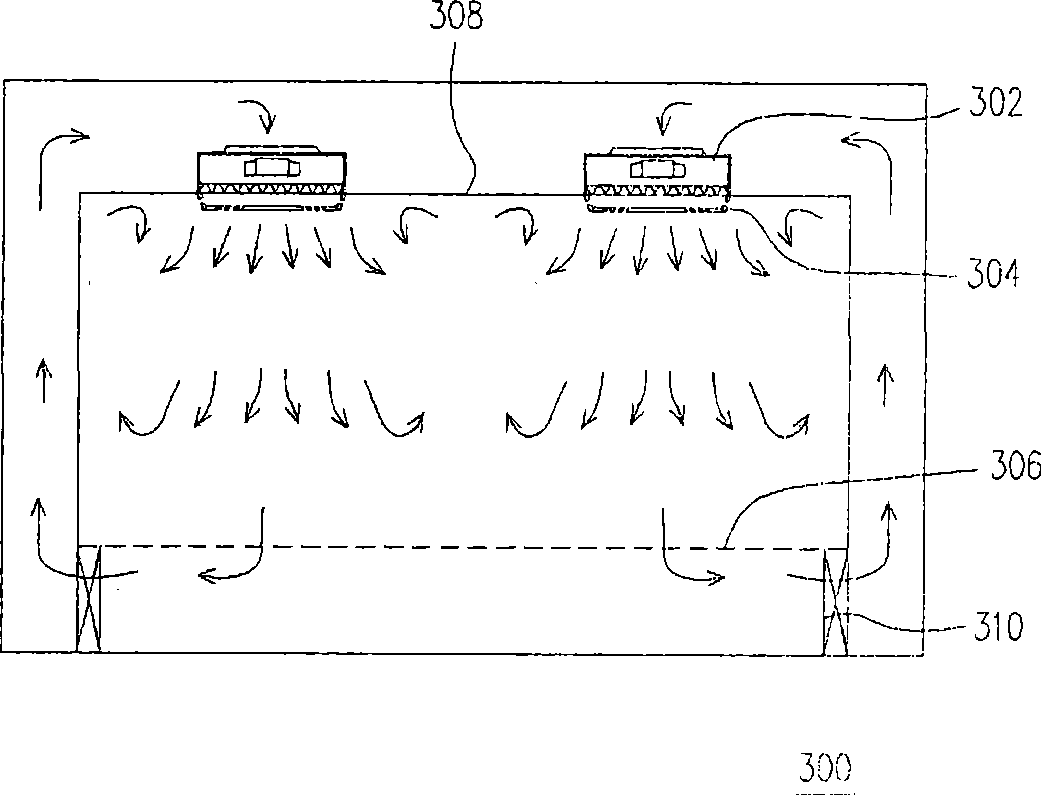

[0053] figure 1 is a schematic cross-sectional view of a fan filter unit according to an embodiment of the present invention. figure 2 is a schematic bottom view of a fan filter unit according to an embodiment of the present invention.

[0054] Please refer to figure 1 , the fan filter unit 100 includes a casing 102 , a fan 104 , a filter 106 and an induced airflow diffuser 108 . The casing 102 is, for example, a rectangular hollow cube, and the top and bottom of the casing 102 are through. The casing 102 has an air inlet 102a and an air outlet 102b, and the air inlet 102a and the air outlet 102b are arranged coaxially, for example. The air inlet 102a is, for example, disposed on the top of the casing 102 . The air outlet 102b is, for example, disposed at the bottom of the casing 102 .

[0055] The fan 104 is disposed inside the casing 102 and located between the air inlet 102a and the air outlet 102b. The shaft of the fan 104 is, for example, connected to a motor (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com