Water coil pipe driving side air-suction top-out-air variable-air-quantity perpendicular upward air curtain

A water coil and variable air volume technology, applied in space heating and ventilation, household heating, lighting and heating equipment, etc., can solve the problem of reducing heat pump heating capacity and energy efficiency ratio, large supply/return air temperature difference, and product quality Difficult to ensure and other problems, to achieve the effect of improving the heat pump heating capacity and energy efficiency ratio, reducing the cooling load of return air, and reducing the operating load of air conditioners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

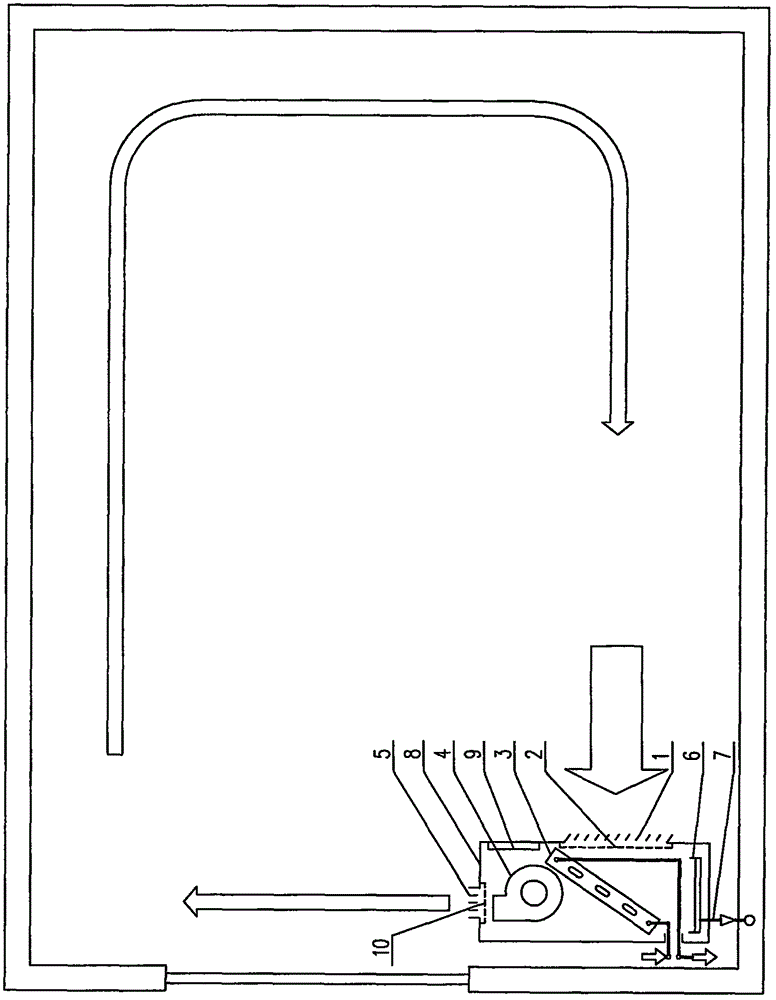

[0029] The embodiment of the water coil drive side suction wind ejected wind variable air volume vertically upward air curtain proposed by the present invention is attached figure 1 As shown, the description is as follows, which consists of: a louvered side return air outlet 1 with an opening length of 1280mm and a height of 450mm; a PM2.5 filter 2 with an opening length of 1280mm and a height of 450mm; High-efficiency aluminum finned water coil with 9.52mm copper sleeve corrugated window 3; variable air volume fan 4 with an air volume of 7-22m3 / min; diversion-type top air supply outlet with an opening length of 1280mm and a width of 195mm 5; opening length 1370mm , a water accumulation tray 6 with a width of 220mm and a depth of 50mm; a drain pipe 7 with a connection diameter of 20mm; a shell 8 with a length of 1380mm, a height of 615mm, and a thickness of 230mm; PE sound-absorbing cotton 9 with a thickness of 15mm; a wet film humidifier 10 with a thickness of 60mm, etc. , wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com