Automatic clamping machine for civilian explosion medium package explosive cartridge

A medicine-packed and automatic technology, applied in the direction of ammunition, ammunition storage, weapon accessories, etc., can solve the problems of slow production speed, the conditions of production lines that cannot meet the large output, and low efficiency, and achieves high production efficiency and complete machine structure. Small, high-speed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be further described in conjunction with the accompanying drawings.

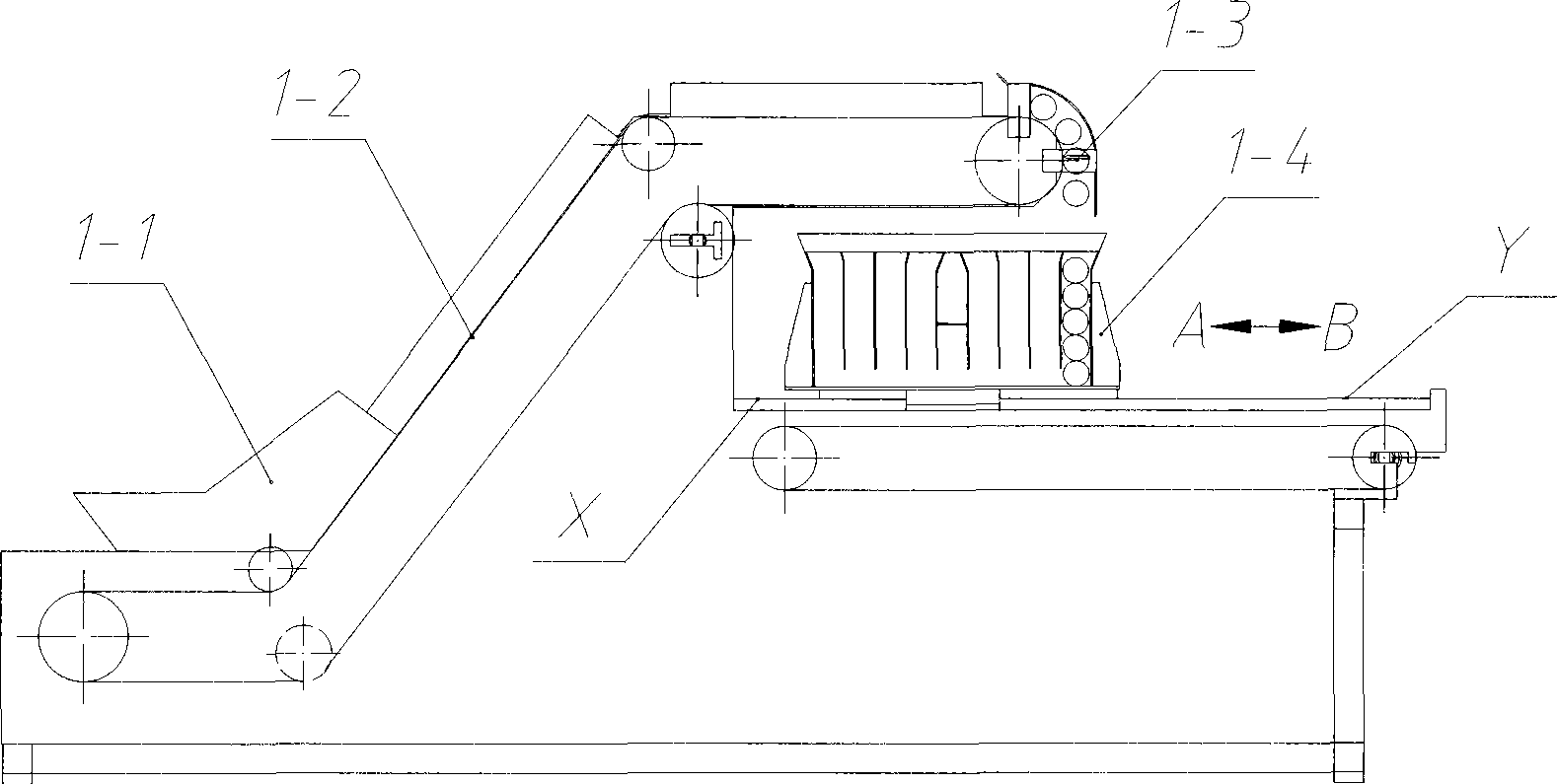

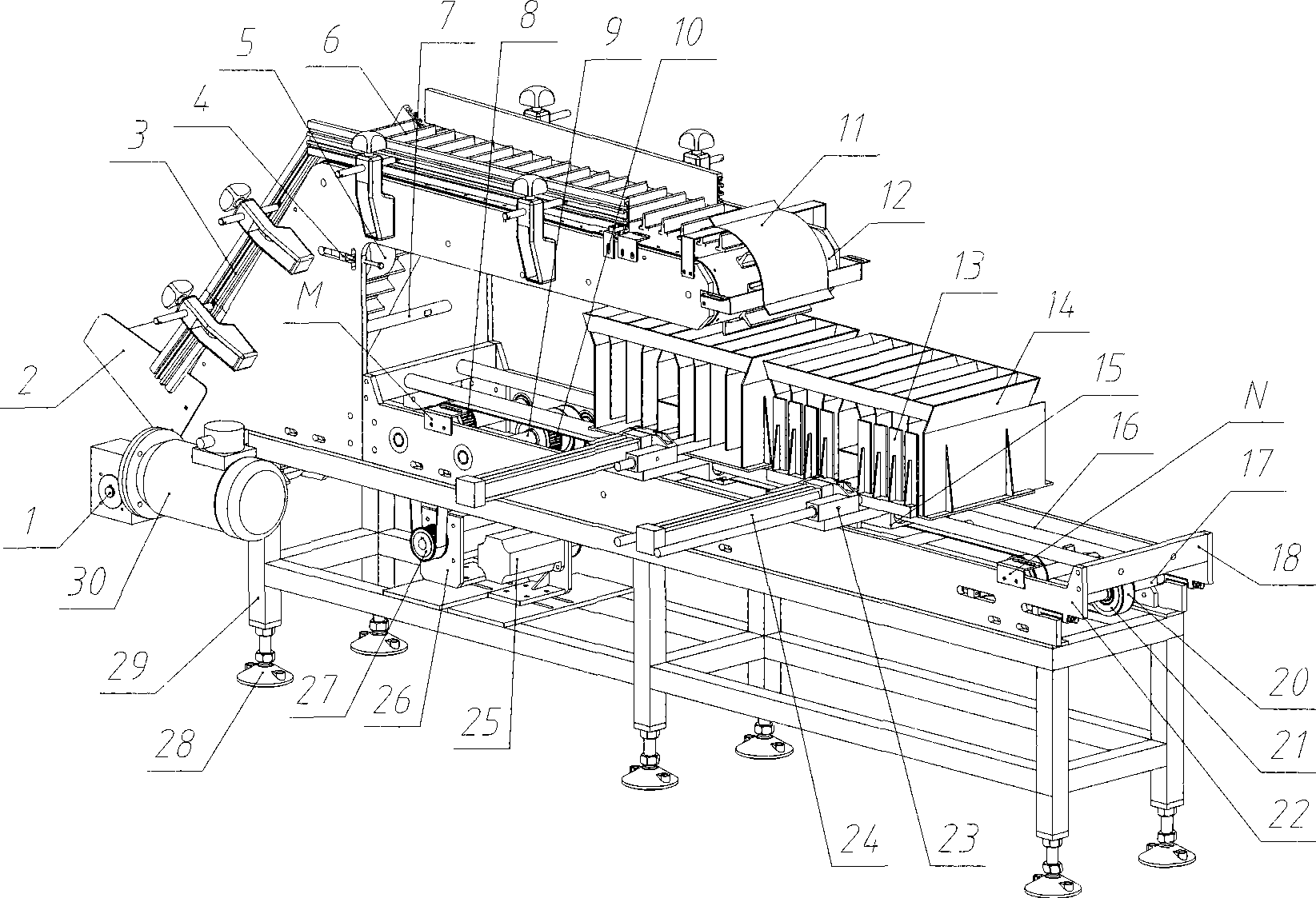

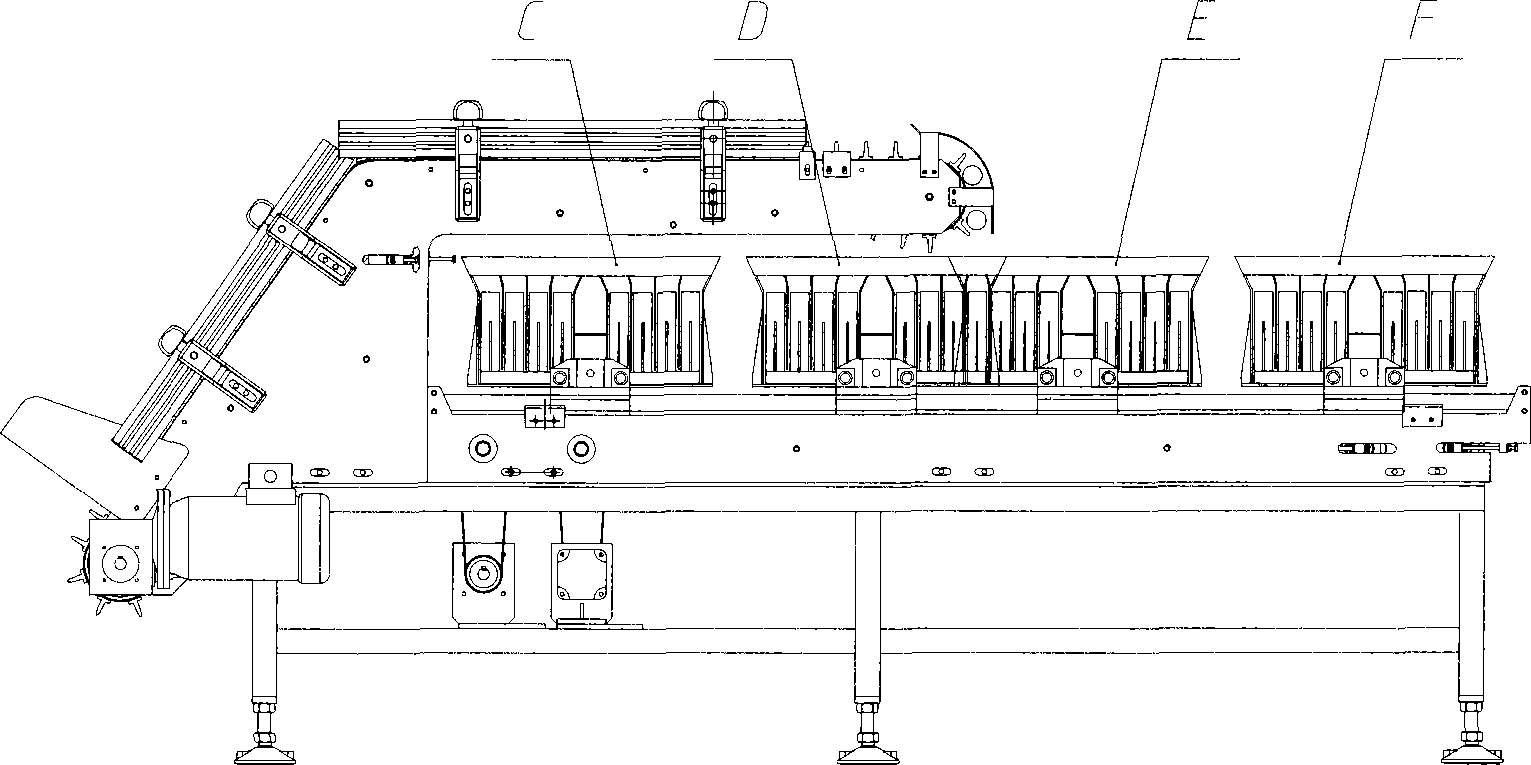

[0022] Such as figure 2 As shown, the present invention consists of a hopper 2, a belt conveying mechanism, two sets of power mechanisms, two sets of drug card mechanisms, a drug drop guard 11, an optical fiber sensor, a guide rod 16, a connecting plate 18, a side plate 22, and a frame 29. The hopper 2 and the drug drop protection plate 11 are installed on the side plate of the belt conveyor of the belt conveying mechanism, the optical fiber sensor is installed on the drug drop protection plate 11, and the sliders 15 of the two sets of drug card mechanisms are respectively sleeved on two guide rods 16, Every guide rod 16 two ends are fixed on the connection plate 18 that links to each other with side plate 22, and guide rod 16, side plate 22, connection plate 18 are installed on the frame 29 as a whole, and the slide block 15 of every cover medicine card mechanism It is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com