Rock formation vibration-testing apparatus and method

A vibration testing and rock formation technology, which is applied to measuring devices, vibration measurements in solids, and vibration measurements, etc., can solve the problems of easily damaged measuring points and poor measurement accuracy, and achieve low cost, high accuracy, and comprehensive test data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

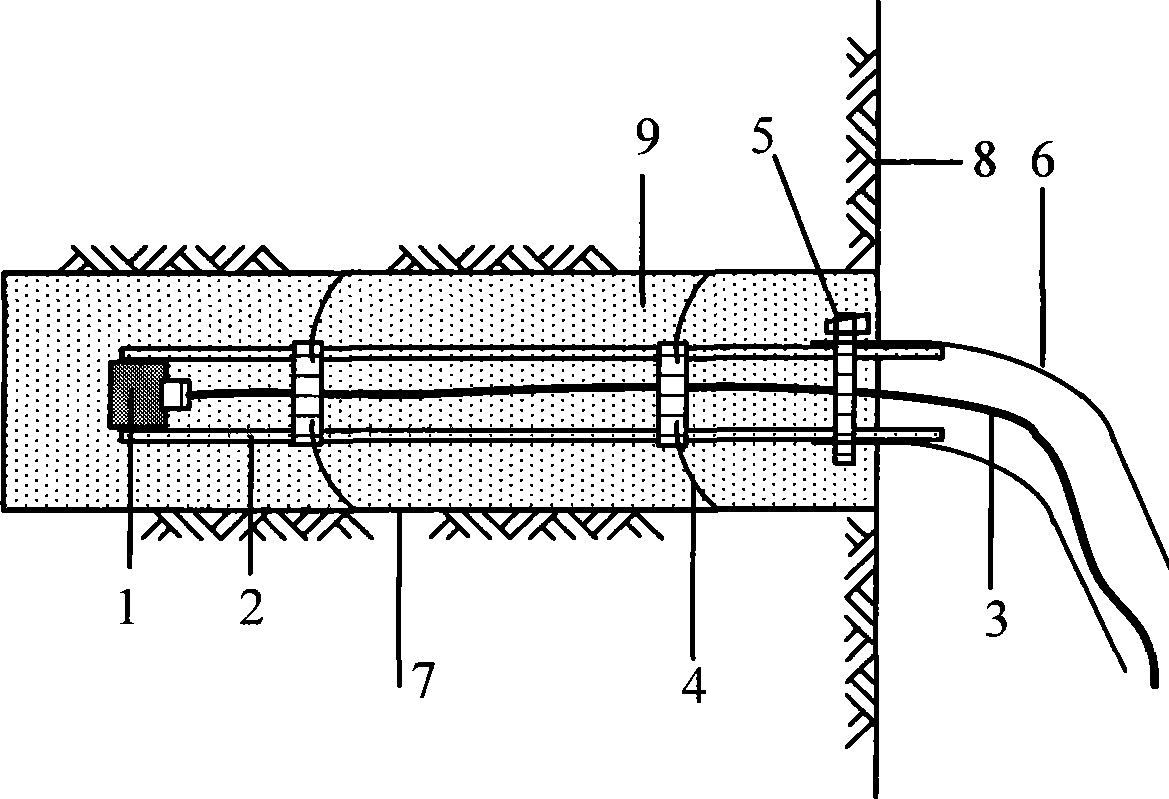

[0029] The project example is a pipe jacking project. The pipe jacking project is located in the silt about 24 meters below the water surface of the bay, the elevation of the center of the pipe jacking is -23.0mm, the thickness of the silt is about 20.1m, and the water depth is about 3.5m. The pipe jacking pipe has an outer diameter of 2.15 meters and a wall thickness of 2.2 cm. Intensified drilling supplementary geological data show that the pile number +528 to +578 is rock, and the total length of the rock section is about 50 meters, and rock blasting is required. Before the blasting construction, the silt in the range of 8.0m×5.5m near the rock interface was reinforced with high-pressure jet grouting piles. Blasting construction is required to ensure that the medium around the rock mass is not disturbed and damaged by the harmful effects of blasting, so as to prevent sudden landslides and water gushing.

[0030] The schematic diagram of the layout of the blasting excavati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com