Stud welding intensity detection apparatus and method

A technology of strength testing and stud welding, which is applied in the direction of measuring devices, using mechanical devices, and using stable torsion to test the strength of materials, can solve the problems of qualified product damage, loss, company waste, etc., to reduce unnecessary waste, Ease of use and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

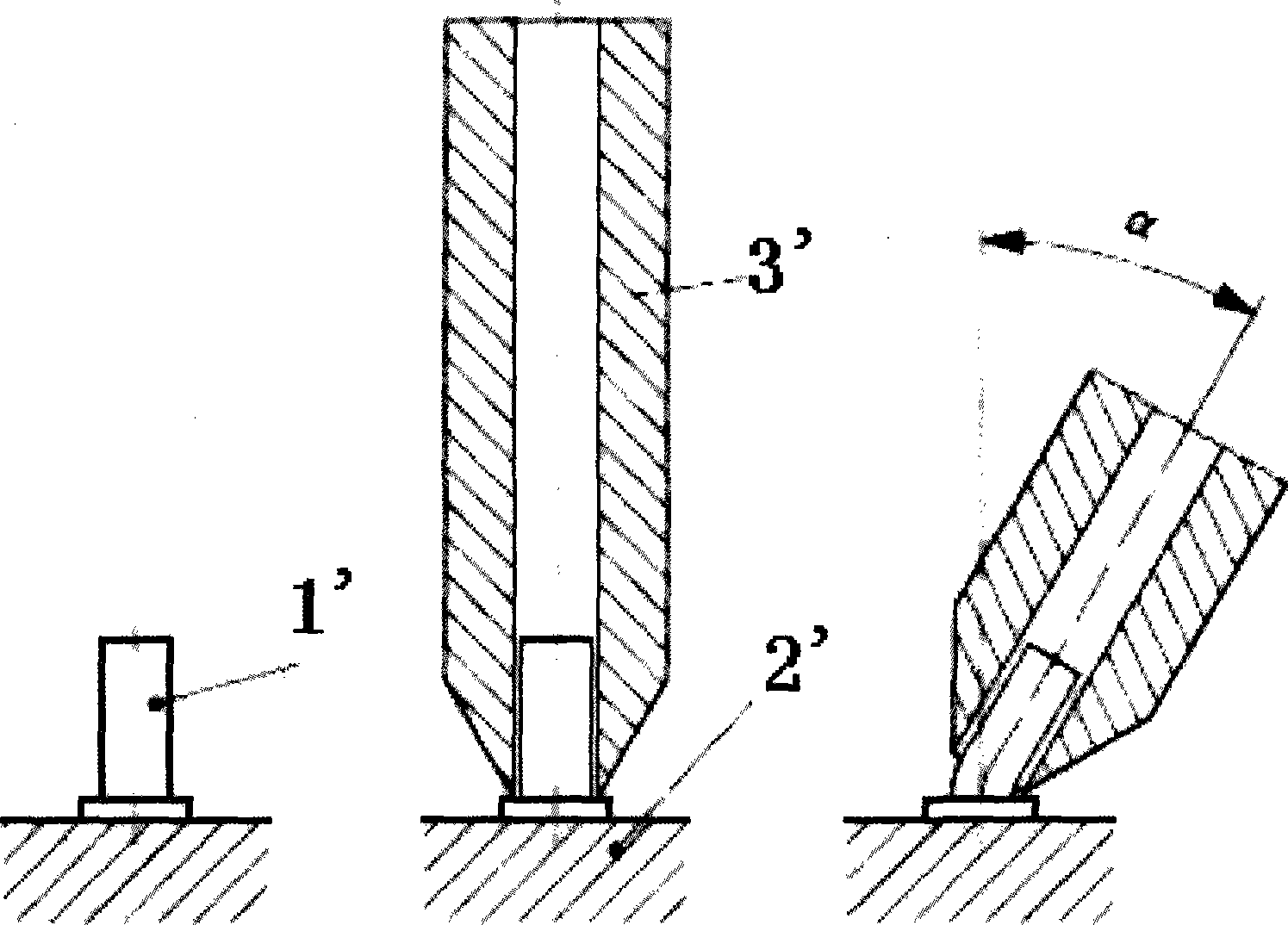

[0047] The scheme of the whole set of devices is explained in conjunction with the accompanying drawings:

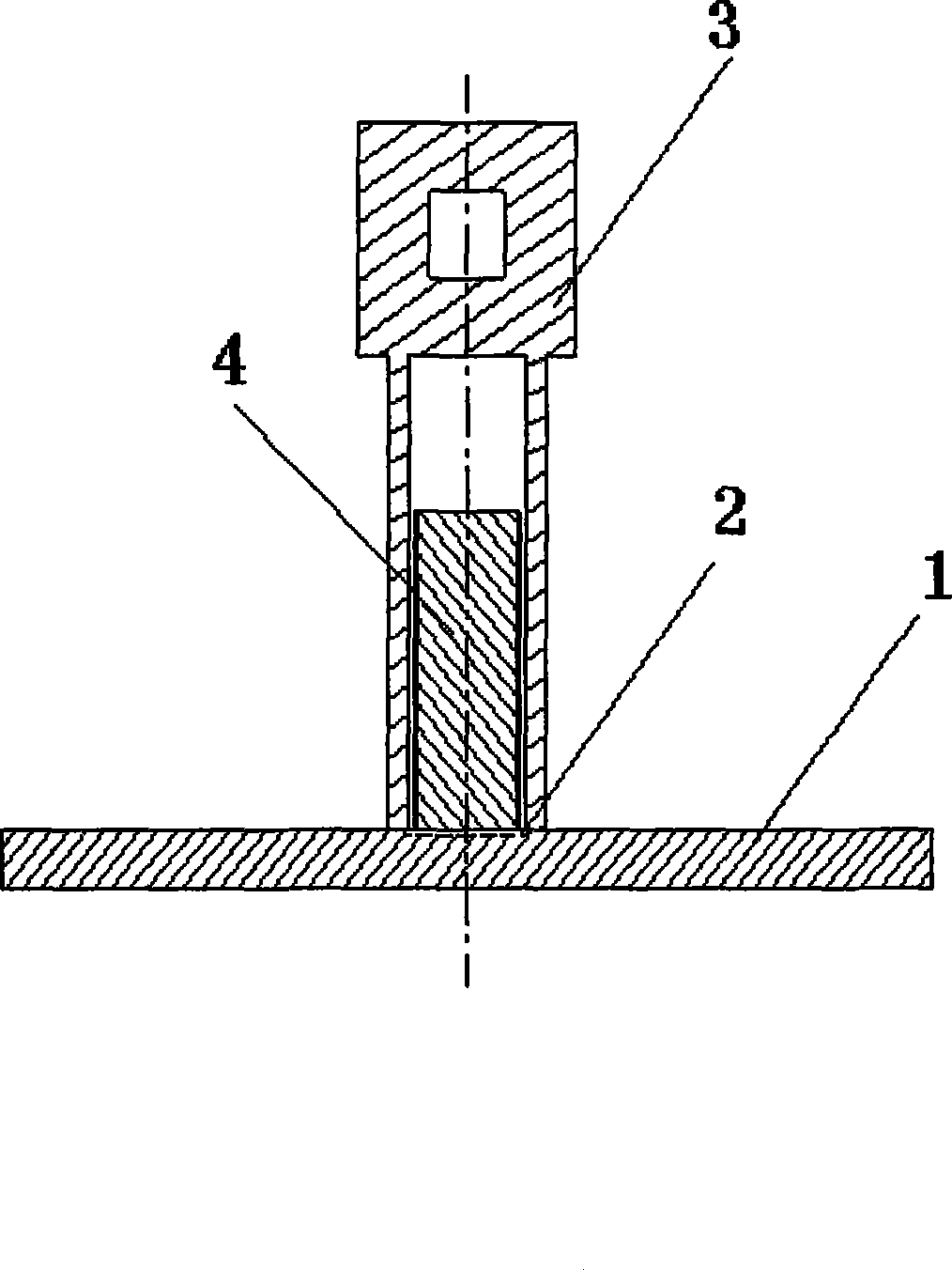

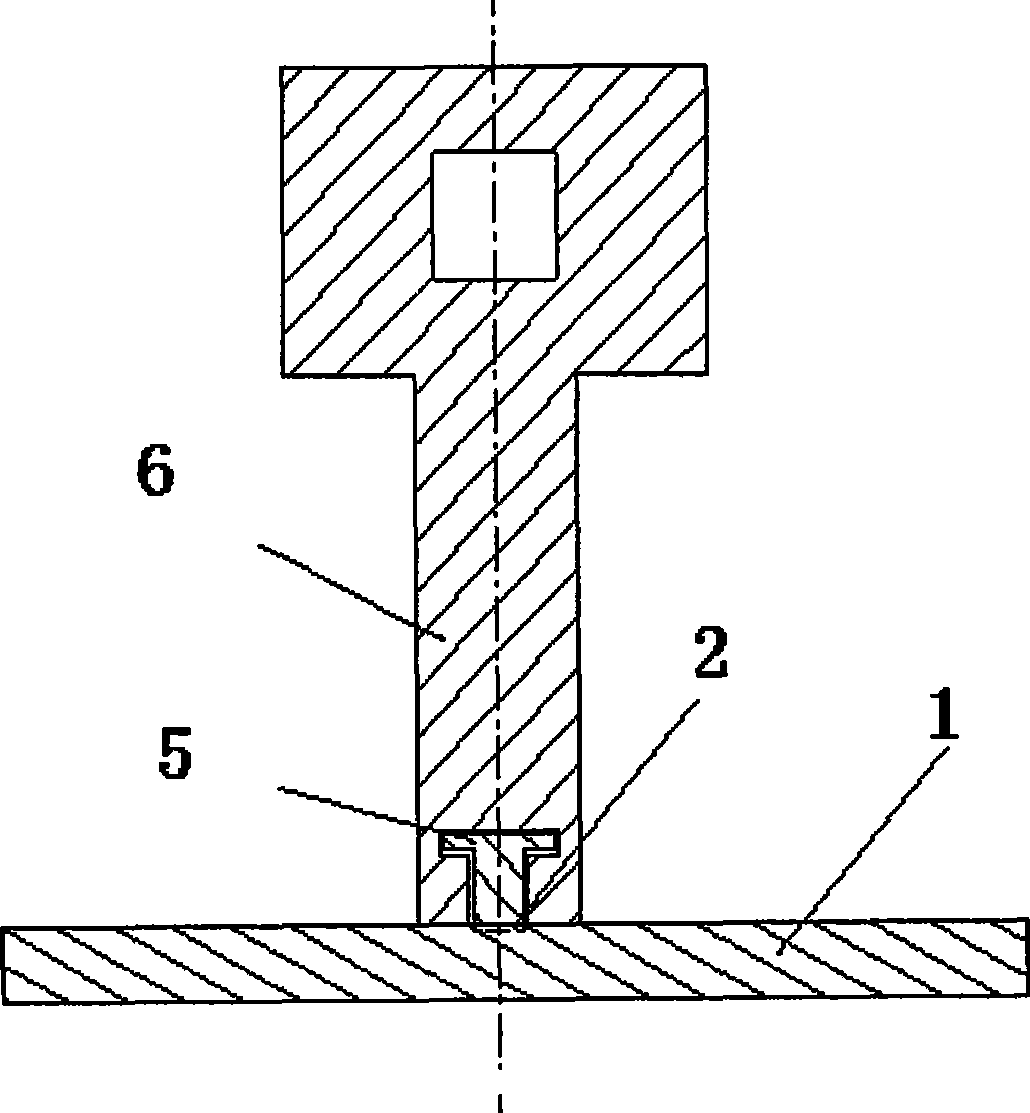

[0048] Screw stud welding welding strength testing device, such as figure 2 As shown, the screws 4 are welded on the workpiece 1, and a welding fusion zone 2 is formed between them. This set of devices uses a fixed value torque wrench to insert into the square hole of the auxiliary sleeve 3 to detect the welding strength. The gap between the screw and the sleeve is required to be controlled at 0.1~0.2mm. Set the torque of the fixed-value torque wrench to a certain value (see the table for the specific value), and the operator twists the wrench. If the wrench can hear the sound of "click, tower" and suddenly slips, it means that the set value is less than For the actual stud weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com