Technique for coating fluorescent powder on LED chip

A technology of LED chips and phosphors, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of influence expansion, affect the uniformity of LED color temperature, color uniformity of color rendering index, uneven distribution of phosphors, etc., and achieve improvement Uniformity of color temperature, solution to the effect of phosphor precipitation and aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

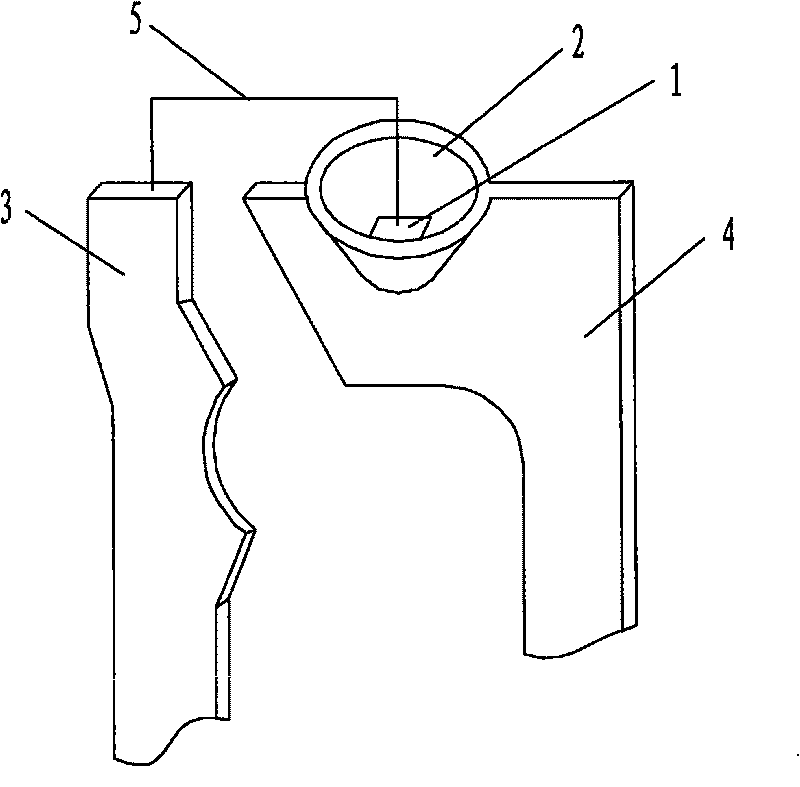

[0019] The process of coating the phosphor powder on the LED chip of the present invention is to coat the phosphor powder on the LED chip more than twice, and the specific steps will be described below with reference to the accompanying drawings.

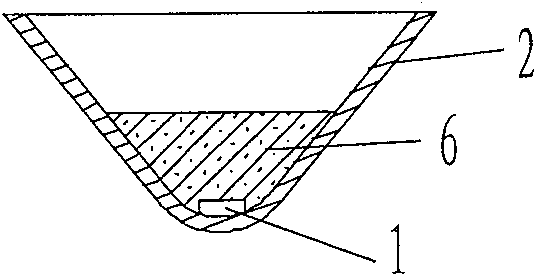

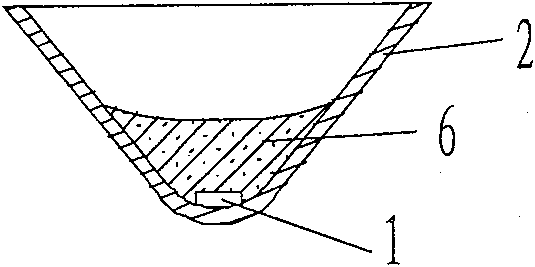

[0020] 1. If figure 1 As shown, according to the conventional process of packaging LEDs, the LED chip 1 is fixed on the bottom of the bracket bowl cup 2 with insulating glue. The bowl cup 2 is connected with the negative lead 4 and the positive lead 3 on one side, and the LED chip 1 and the positive lead 3 are welded. Between the electrode leads 5. At the same time, mix the fluorescent powder and glue (white light glue, epoxy resin, etc.), the mass ratio of glue and phosphor powder is between 15:1-25:1, stir evenly, and prepare a low-concentration fluorescent glue after vacuuming. Apply the low-concentration fluorescent glue to the bowl 2 for the first application, and the coating depth is 1 / 2-2 / 3 of the depth of the bowl, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com