Flame-proof battery

A technology for batteries and flame retardants, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of reducing the overall performance of the battery, reducing the battery life, reducing the ionic conductivity of the electrolyte in the battery, etc. The effect of explosion, simplicity of implementation, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

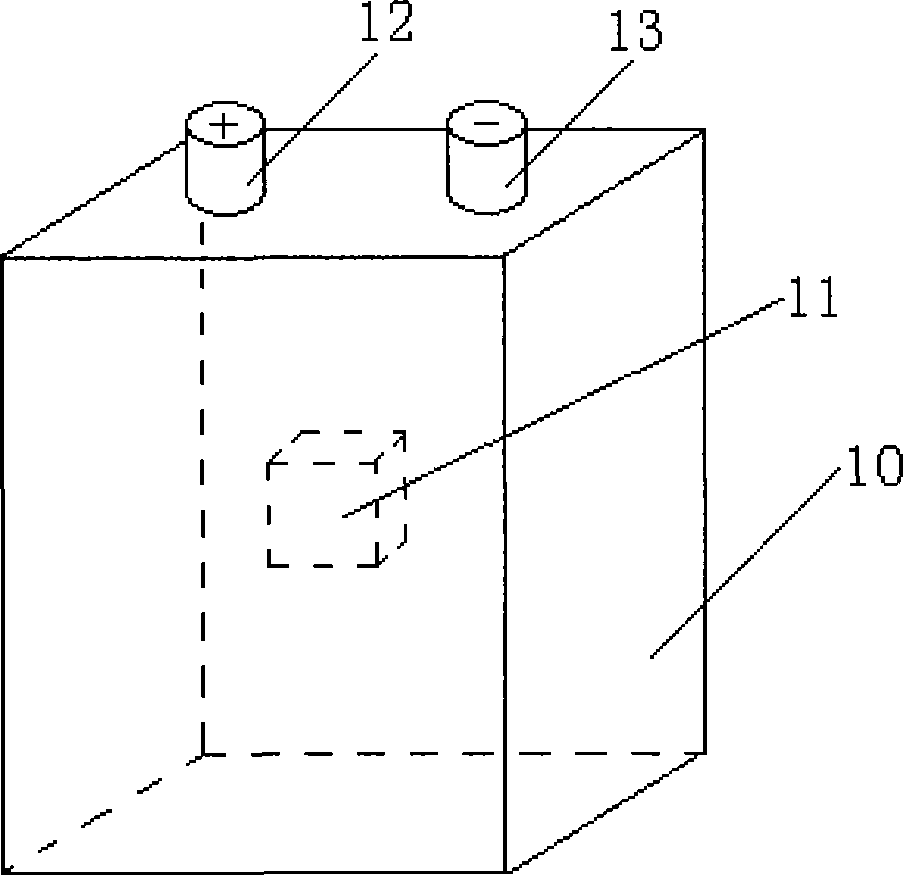

Embodiment 1

[0019] The material of the airtight container 11 is an insulating material. If the material is crystalline, its melting point is 50°C to 150°C; if it is amorphous, its melting temperature is 50°C to 150°C. Before the explosion, the airtight container 11 melts and the flame retardant in it flows into the electrolyte, thereby preventing the chemical reaction of the electrolyte and preventing the cell from exploding. The electrolyte properties of different batteries are different, and the critical temperature of the chemical reaction of the electrolyte is also different. The material melting point or melting temperature of the above-mentioned airtight container 11 is a range value proposed in consideration of the characteristics of different electrolytes of the current battery. Personnel should understand that, according to the characteristics of the electrolyte in the specific battery, the melting point or melting temperature of the material of the airtight container 11 is also d...

Embodiment 2

[0025] The maximum pressure of the overall structure of the airtight container 11 is designed to be 0.2Mpa to 200Mpa, that is, before the pressure in the battery cell 10 rises to explode, the airtight container 11 will burst and the flame retardant inside will flow into the electrolyte, thereby preventing The chemical reaction of the electrolyte prevents the cell from exploding. The maximum pressure value of different batteries 10 is different. Taking lithium-ion batteries for ordinary mobile phones as an example, the pressure value of batteries is generally between 75Mpa and 150Mpa. Considering the performance of the flame retardant and the controllability of the electrolyte reaction Generally, when the pressure in the cell 10 reaches 2Mpa-25Mpa, it is necessary to control the reacting electrolyte, otherwise it will react violently and is difficult to control. Those skilled in the art should understand that for different electrolytes and flame retardants, the set critical pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com