Automatic tuning control method of arc suppression coil by compensation susceptance incremental method

An arc suppression coil and susceptance compensation technology, applied in the electrical field, can solve the problem that there is no mature method for tuning measurement and control, and achieve the effects of clear thinking, low cost and simple calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

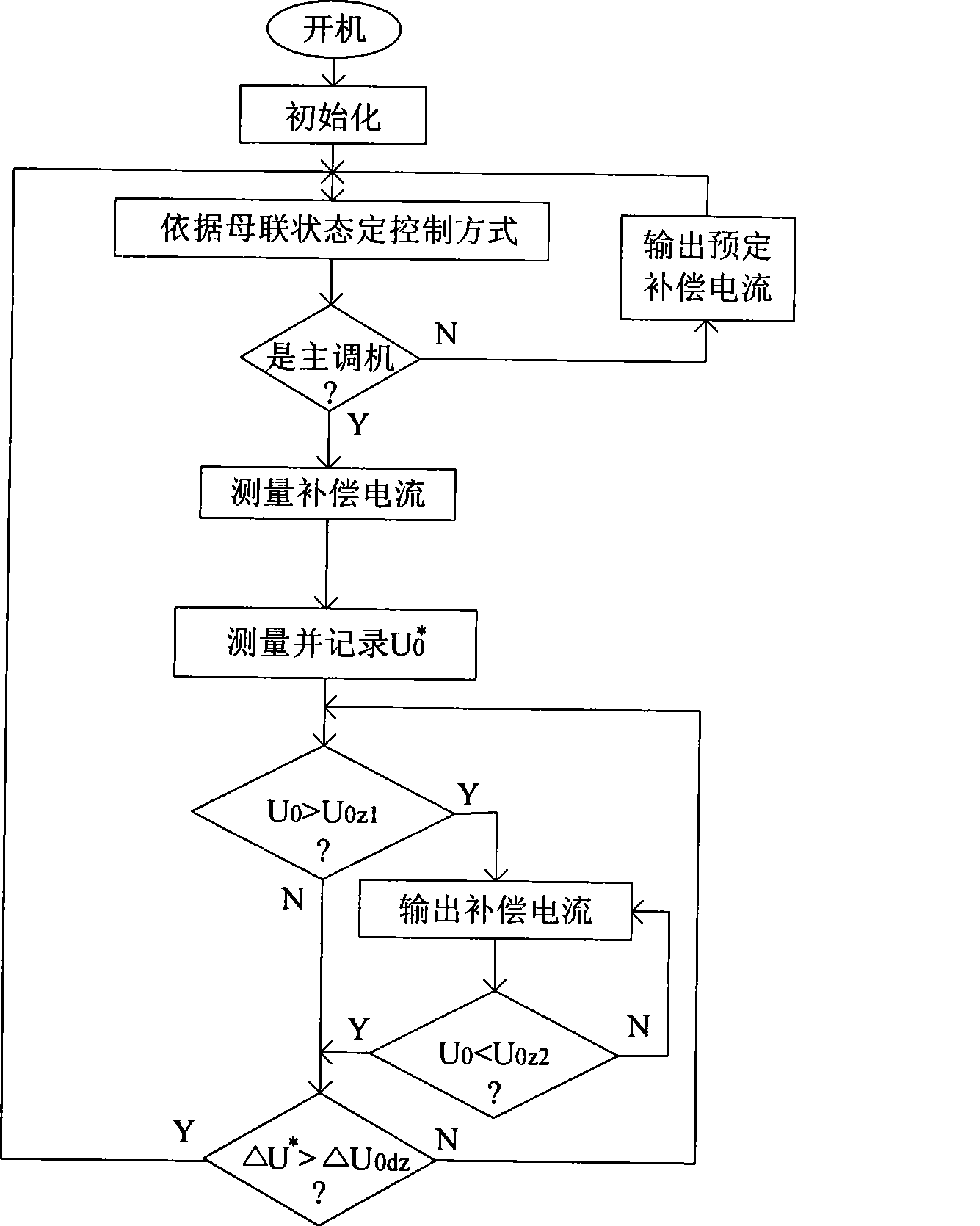

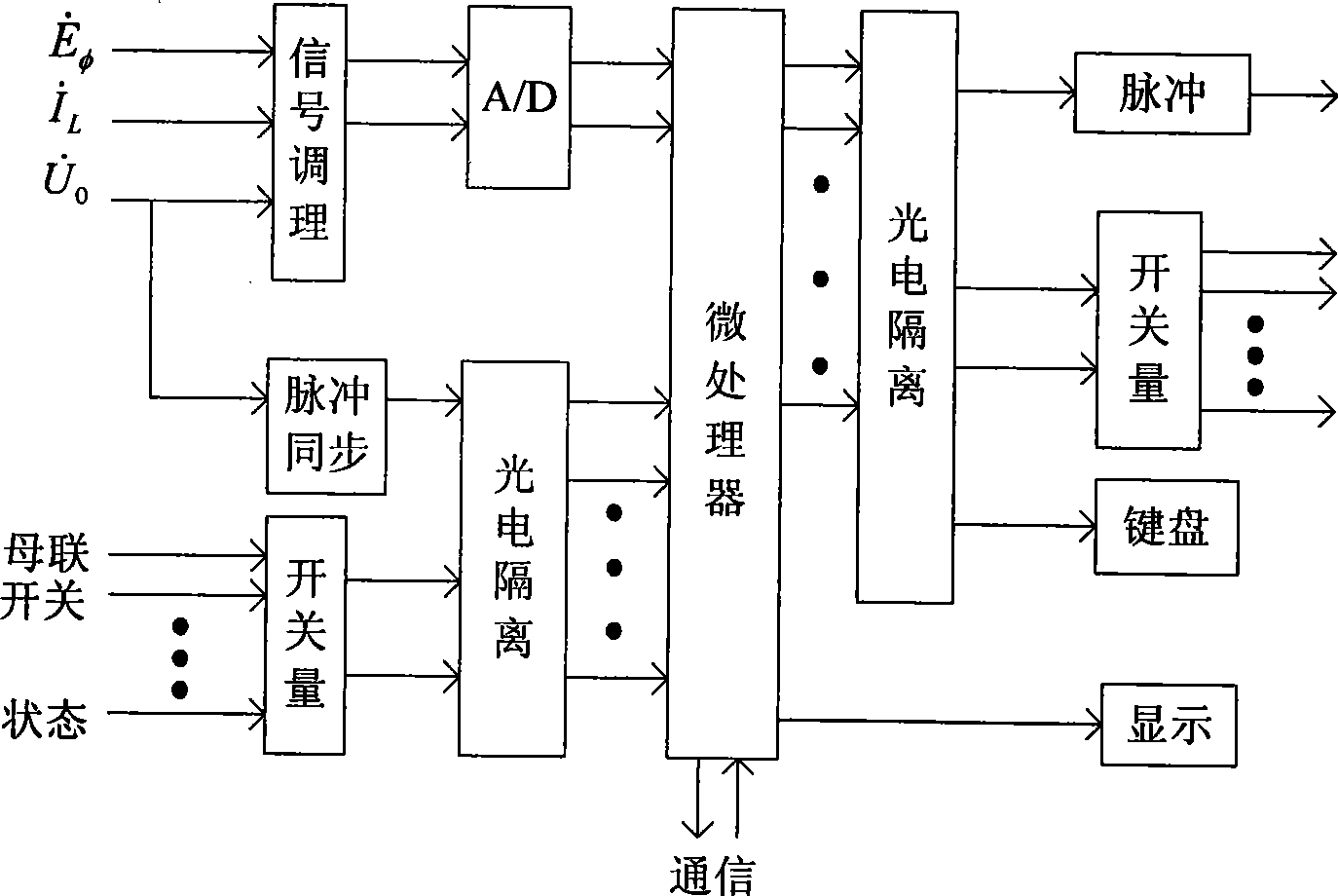

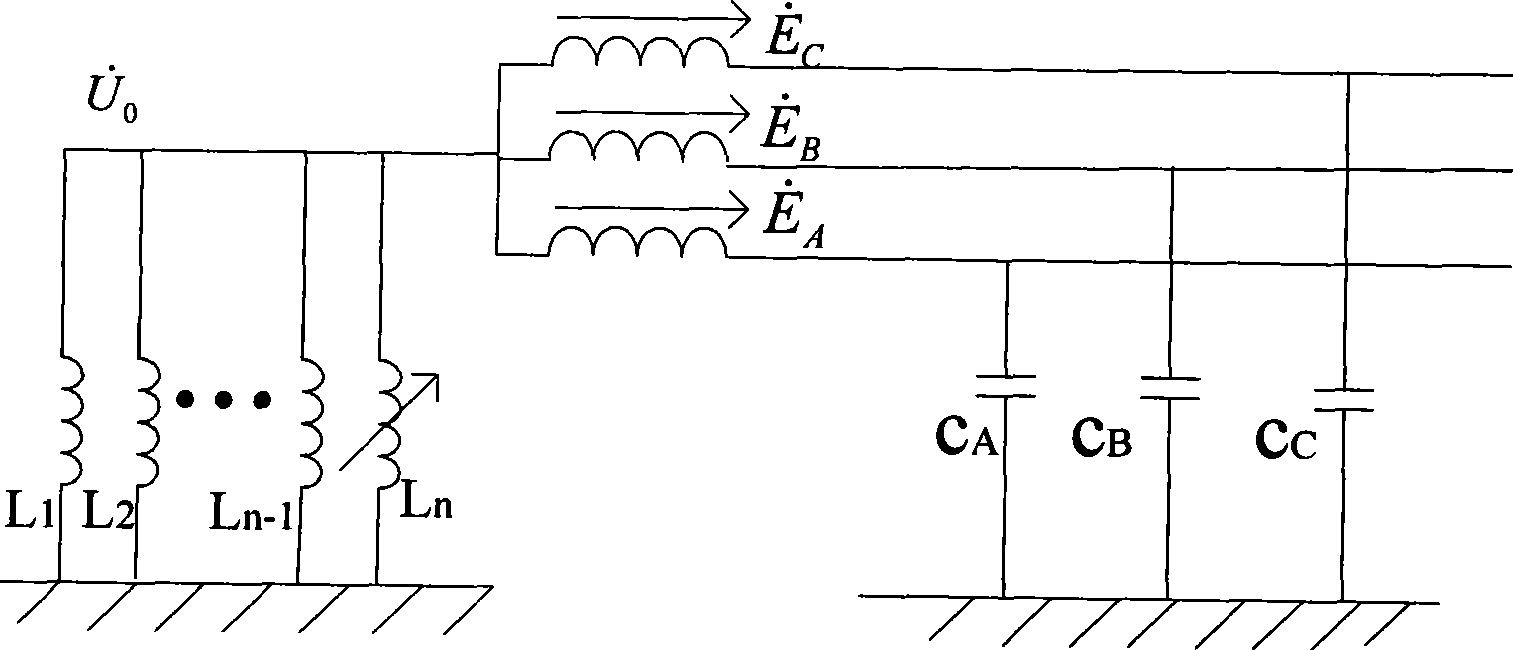

[0024] In order to achieve the above object, the technical solution of the present invention takes the following 5 steps to realize:

[0025] ① Determine whether the arc-suppression coil to be tuned and controlled is a "main-tuning" machine or a "non-main-tuning" machine according to the opening and closing state of the bus tie switch at the first time when the arc-suppression coil is powered. If it is a "non-main tuning" machine, then "pre-output fixed compensation inductance", this "pre-output fixed compensation inductance" is determined according to the installation position and compensation capacity of the arc-suppression coil and programmed into the arc-suppression coil in the tuning control program. Then monitor the opening and closing status of the bus tie switch in real time, and be ready to change the tuning control mode of the arc suppression coil at any time. If it is the "main tuning" machine, then proceed to step ②.

[0026] ②Measure and record the compensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com