Hydrogenation method for brown coal directly liquefied circulating solvent

A circulating solvent, direct technology, applied in the field of hydrogenation of lignite direct liquefaction circulating solvent, can solve the problem of not being able to provide free hydrogen, and achieve the effect of avoiding a large excess of hydrogen, reducing the possibility, and homogenizing the temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

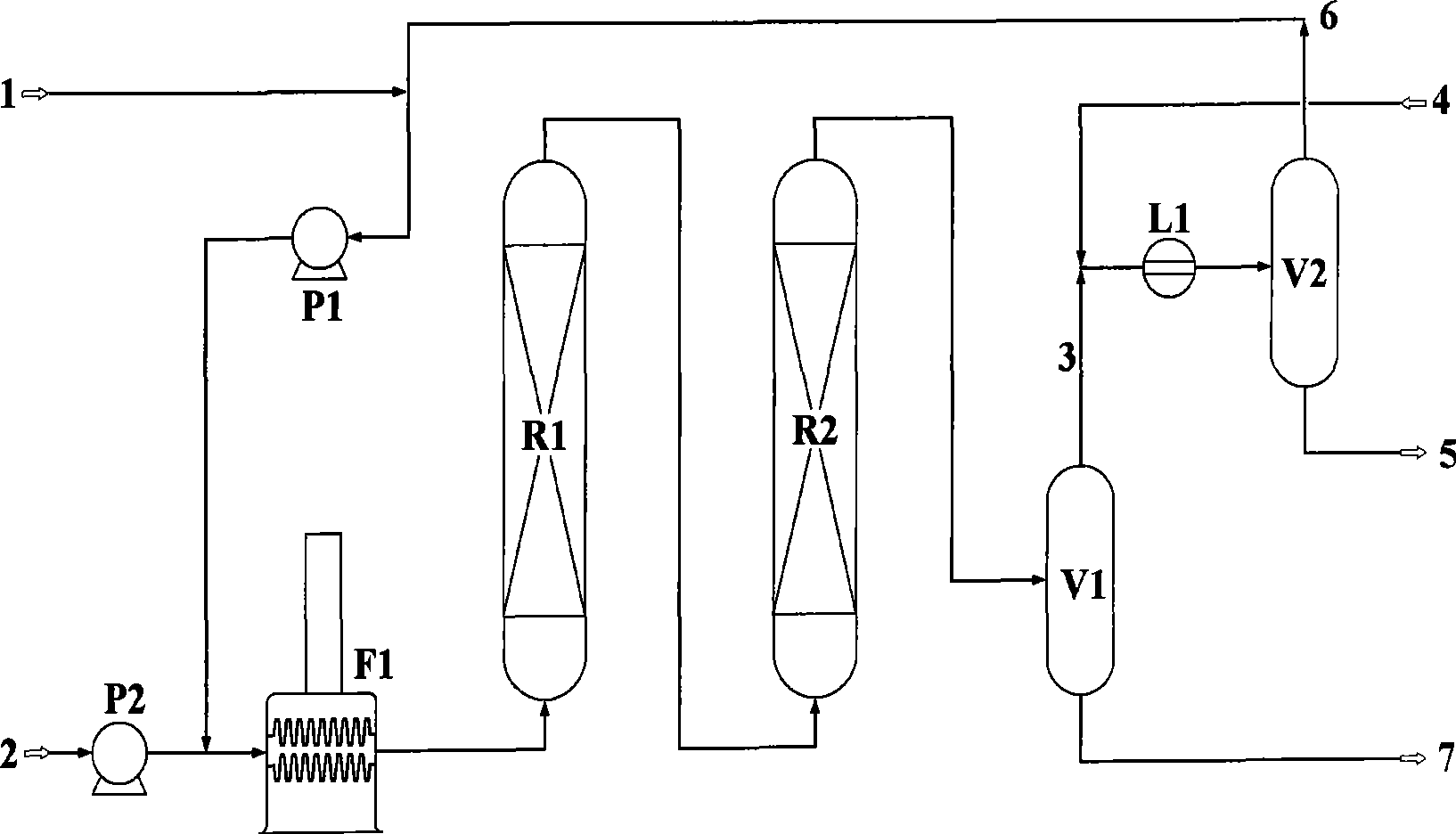

Method used

Image

Examples

Embodiment 6

[0085] The pressure in Example 6 is the highest, which is beneficial to the hydrogenation reaction. In order to prevent the hydrogenation saturation of the product from being too high, the lowest hydrogen-to-oil ratio and the largest space velocity were adopted, so the hydrogenated aromatics content (83.22m%) of this example was only slightly higher than that of Example 5 (80.13m%) 3.09m%.

[0086] The data in Table 2 show that due to the lower content of non-ideal components in feedstock 2, the hydrogenated aromatics content of its products is still higher than that of feedstock 1 despite its higher reaction space velocity.

Embodiment 7

[0087] Example 7 uses the mixed products of Examples 1-4 as a solvent to conduct lignite hot-melt catalysis test, and Example 8 uses a non-hydrogenated circulating solvent to carry out lignite hot-melt catalysis test, and the two are compared. The tests were all carried out in a 2000ml autoclave. After the reaction material was in good shape, it was pressurized with nitrogen to the reaction pressure, the pressure was controlled to be constant, and the temperature was raised to react under stirring. The test results are shown in Table 3.

[0088] Table 3 Comparison of lignite hot-melt catalysis test with hydrogenation solvent and non-hydrogenation solvent

[0089] Example 7 8 solvent type hydrogenation Without hydrogenation Reaction pressure, MPa 5.2 5.2 Reaction temperature, °C 400 400 Response time, min 30 30 Agent-to-coal ratio, m / m 3:1 3:1 Catalyst, g 1.0 1.0 Input lignite (daf), g 250 250 Add solvent (daf),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com