Fibrous structure

A fiber structure and fiber technology, applied in fiber processing, textiles, papermaking, clothing, etc., can solve the problems of inability to remove, drill into fabrics, etc., and achieve the effect of excellent cleaning durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

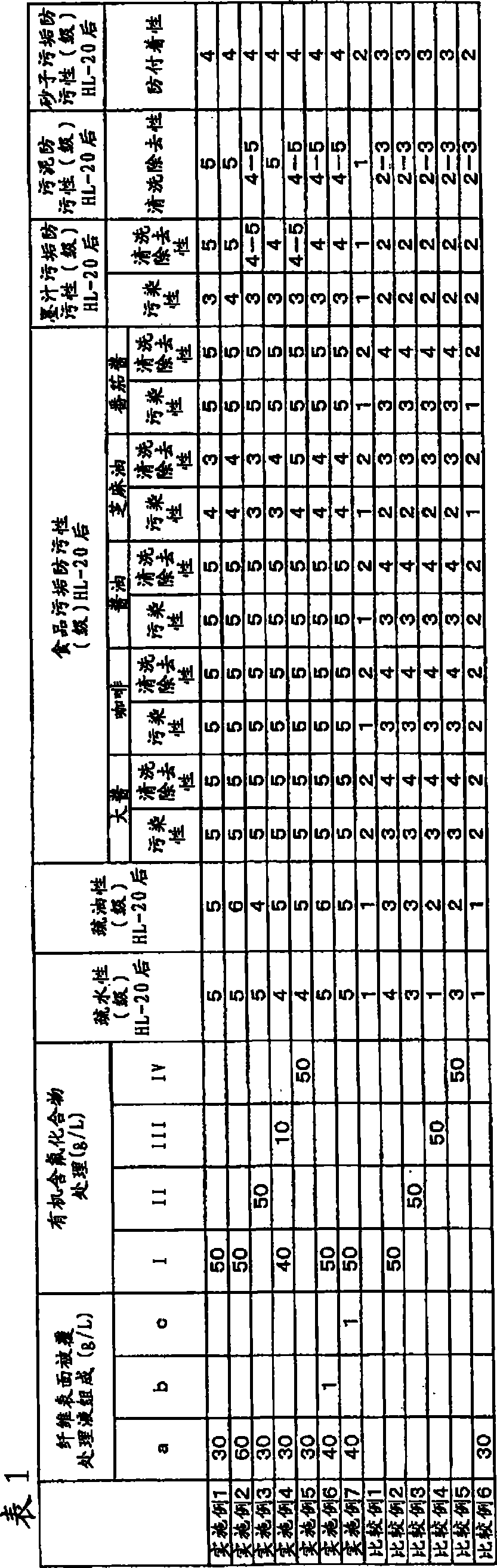

Embodiment 1~7、 comparative example 1~6

[0107] Using 84dtex, 72F twisted textured yarn made of polyethylene terephthalate for warp and weft, it was woven into a plain weave, and then the fabric was passed through an opensoaper type continuous refiner at a temperature of 95°C Refined, washed with hot water at 60°C, washed with water, dried at 130°C, dyed light yellow at 130°C by flow dyeing, washed with hot water, dried at 130°C, The setting was performed with a pin tenter at a temperature of 170° C. to obtain a fabric having a warp density / weft density of 138 / 90 pieces / 2.54 cm. This dyed fabric was subjected to the following fiber surface coating treatment and organic fluorine-containing compound treatment, and the properties of the obtained fabric were evaluated, and the results are shown in Table 1.

[0108]

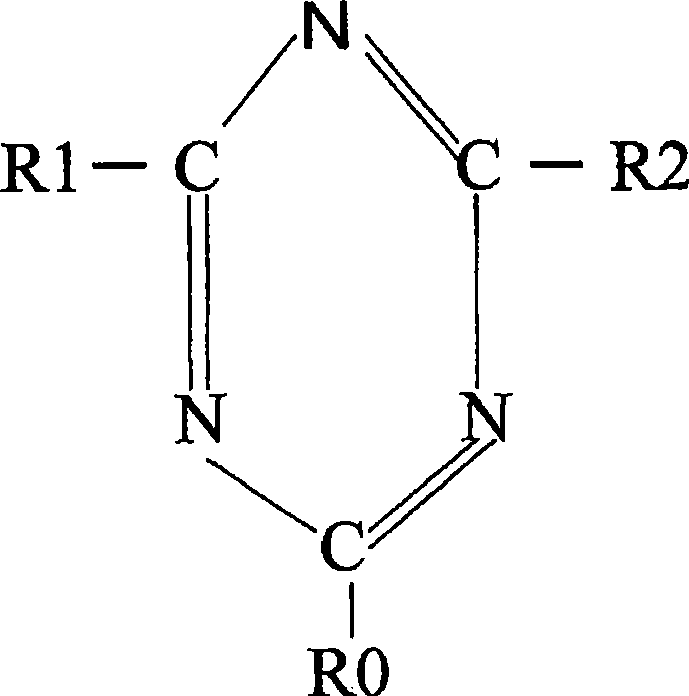

[0109] (a) Pekkan M-3 (triazine ring compound solid content 80%, manufactured by Dainippon Inki Chemical Industry Co., Ltd.)

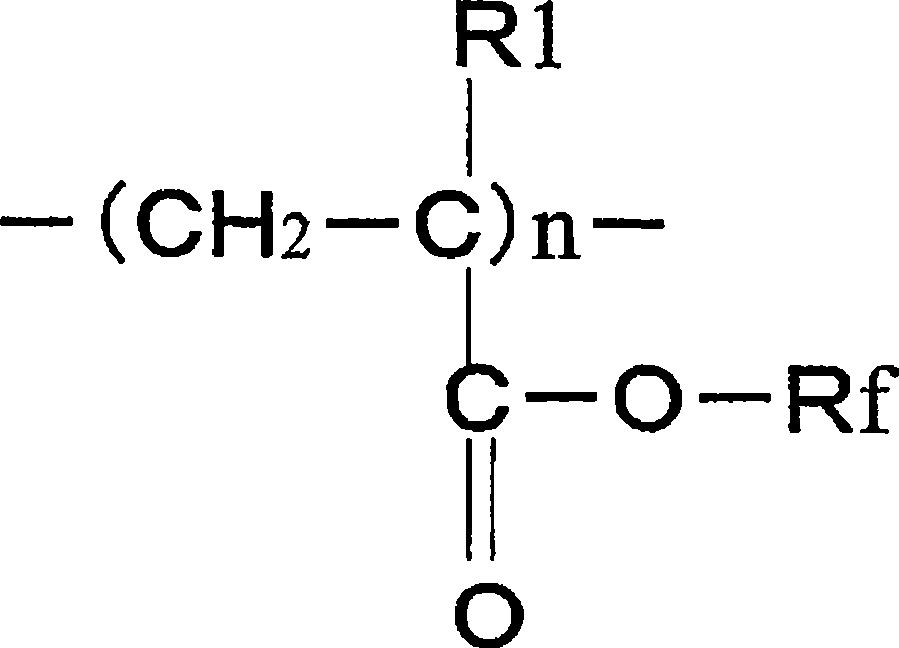

[0110] (b) F-200 (20% solid content of fluorine-based compound manufactured b...

Embodiment 8~12、 comparative example 7~10

[0123] Using 44dtex and 36F yarn made of polyethylene terephthalate and 44dtex polyurethane elastic yarn made by Opolontech Co., Ltd., a tricot warp knitting machine with two reeds of gauge 32, front reed Polyethylene terephthalate yarn is used, and polyurethane yarn is used for the rear reed, and 80% by weight of polyethylene terephthalate yarn and 20% by weight of polyurethane yarn are used, and it is woven into warp pile and warp plain. organize. The knitted fabric was then refined at a temperature of 95°C using a flat-wash continuous refiner, washed with hot water at a temperature of 60°C, then washed with water, then dried at a temperature of 130°C, and then washed with a needle at 190°C The plate tenter was set, then dyed to beige at a temperature of 130°C by liquid dyeing, washed with boiling water, dried at 130°C, and set again with a pin tenter at a temperature of 160°C, thereby obtaining a tandem Density × row density is 62 wales / 2.54cm×104 ridges / 2.54cm, and the un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com