Process for the preparation of dimethyl ether

A technology of dimethyl ether and methanol, which is applied in the field of preparation of dimethyl ether, can solve the problems of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

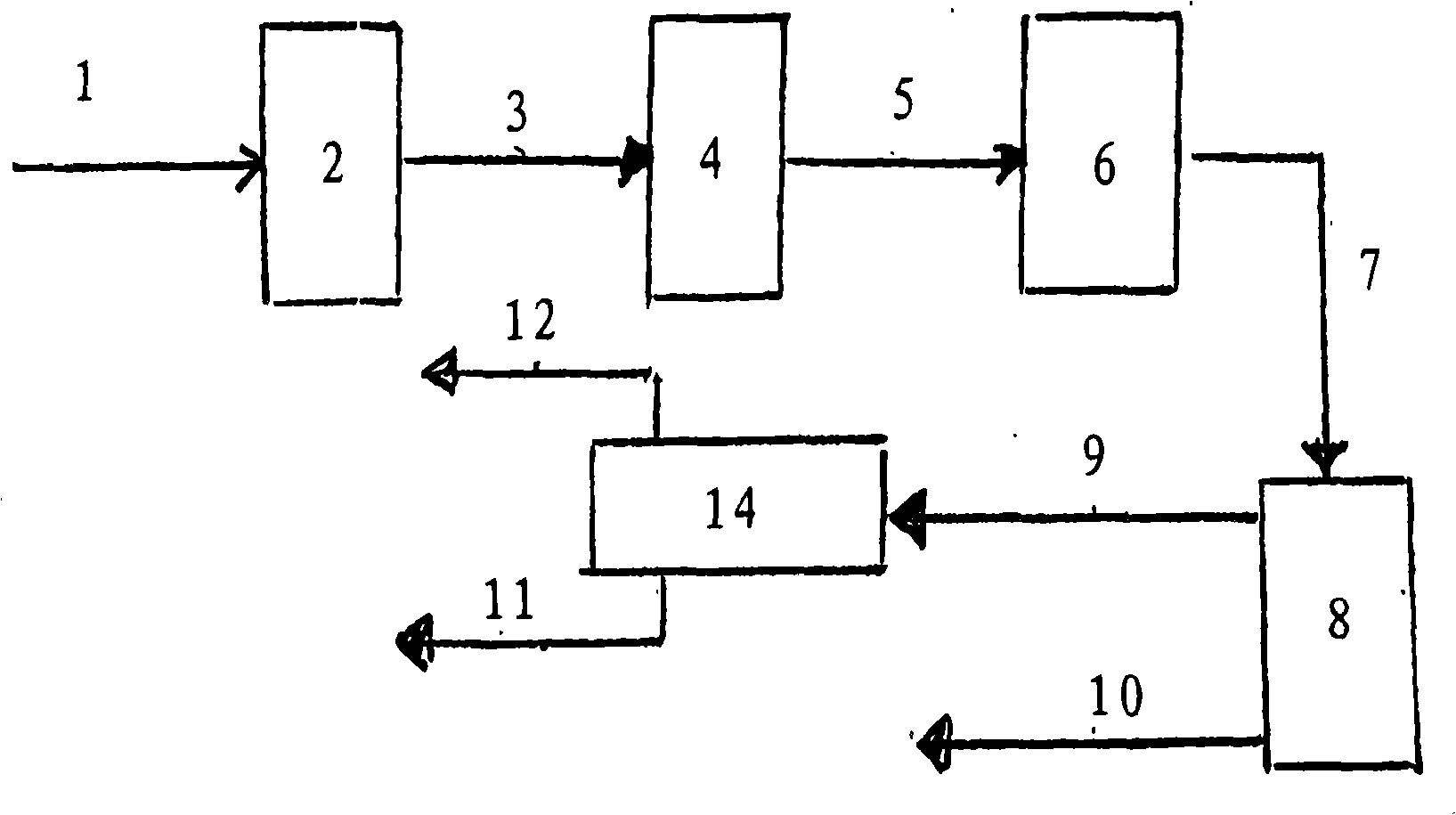

[0031] Using the above and shown in figure 1 The effects of the methods in are summarized in Tables 1-3 below. Product mixture 3, which had been cooled to 130°C, had the composition shown in Table 1.

[0032] Table 1

[0033] components

N m 3 / h

Volume %

H 2

37361

17.53

h 2 o

1255

0.59

N 2

19182

9.00

CO

35582

16.69

CO 2

69187

32.46

3173

1.49

DME

47386

22.23

[0034] The treated effluent 5 of the absorbent unit 4 , which has been washed with potassium carbonate, is at a temperature of 71° C. when it is introduced to the solid adsorbent 6 . The composition of Effluent 5 is shown in Table 2 and the composition of Effluent 7 from Adsorbent 6 is shown in Table 3.

[0035] Table 2

[0036] components

N m 3 / h

Volume %

H 2

37361

26.17

h 2 o

165

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com