Mounting method with detachable rubber water stop mounted inside

A technology of a rubber water stop belt and an installation method, which is applied in the directions of buildings and building structures, can solve problems such as water leakage, and achieve the effects of firm installation, water infiltration prevention, and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

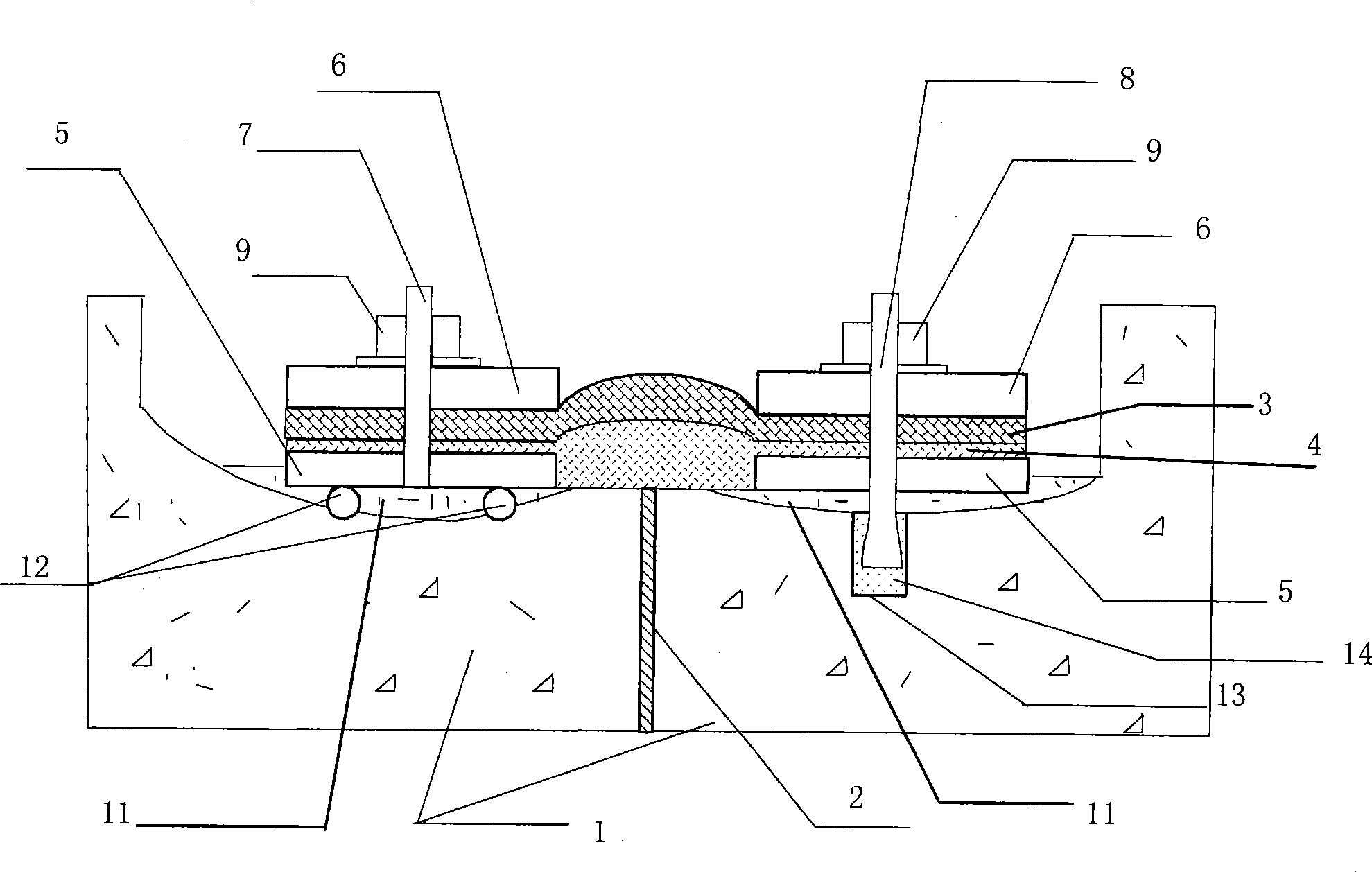

[0020] The concrete on the left side of settlement joint 2 has reinforcement in it, while the concrete on the right side has no reinforcement in it.

[0021] Water-soluble polyurethane grouting, plugging double fast cement and polystyrene plastic filler are sequentially injected into the settlement joint 2 first.

[0022] Chisel the concrete on the left side of the settlement joint until the steel bar 12 is exposed, and weld the bottom steel plate 5 on the steel bar;

[0023] There is no steel bar in the concrete on the right side of the settlement joint, so a hole 13 is punched in the concrete, and epoxy cement 14 is filled in the hole to fix the expansion bolt 8 . Weld and fix the bottom steel plate on the expansion bolts, and weld and close all the gaps between the expansion bolts and the bottom steel plate.

[0024] Use epoxy resin grouting 11 to seal the gap between the bottom steel plate and the concrete, and smear polysulfide rubber on the bottom steel plate surface an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com