Heat decomposition gas processing method and apparatus of carbonization processing system containing water

A carbonization treatment and gas treatment technology, applied in the combustion method, combustion air/fuel supply, non-flammable liquid/gas transportation, etc., can solve the problem of increasing fuel consumption rate of auxiliary fuel, and achieve low fuel consumption rate , the effect of maintaining the fuel consumption rate

Active Publication Date: 2009-02-25

MITSUBISHI HEAVY IND LTD

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0021] as inhibition from containing the NH 3 The combustion method for converting gas to NOx is effective for low-NOx combustion based on high-temperature reduction combustion using an auxiliary fuel composed of fossil fuels. However, in this case, a large amount of auxiliary fuel is required, and the fuel consumption rate of the auxiliary fuel tends to increase. , there is room for improvement in this

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

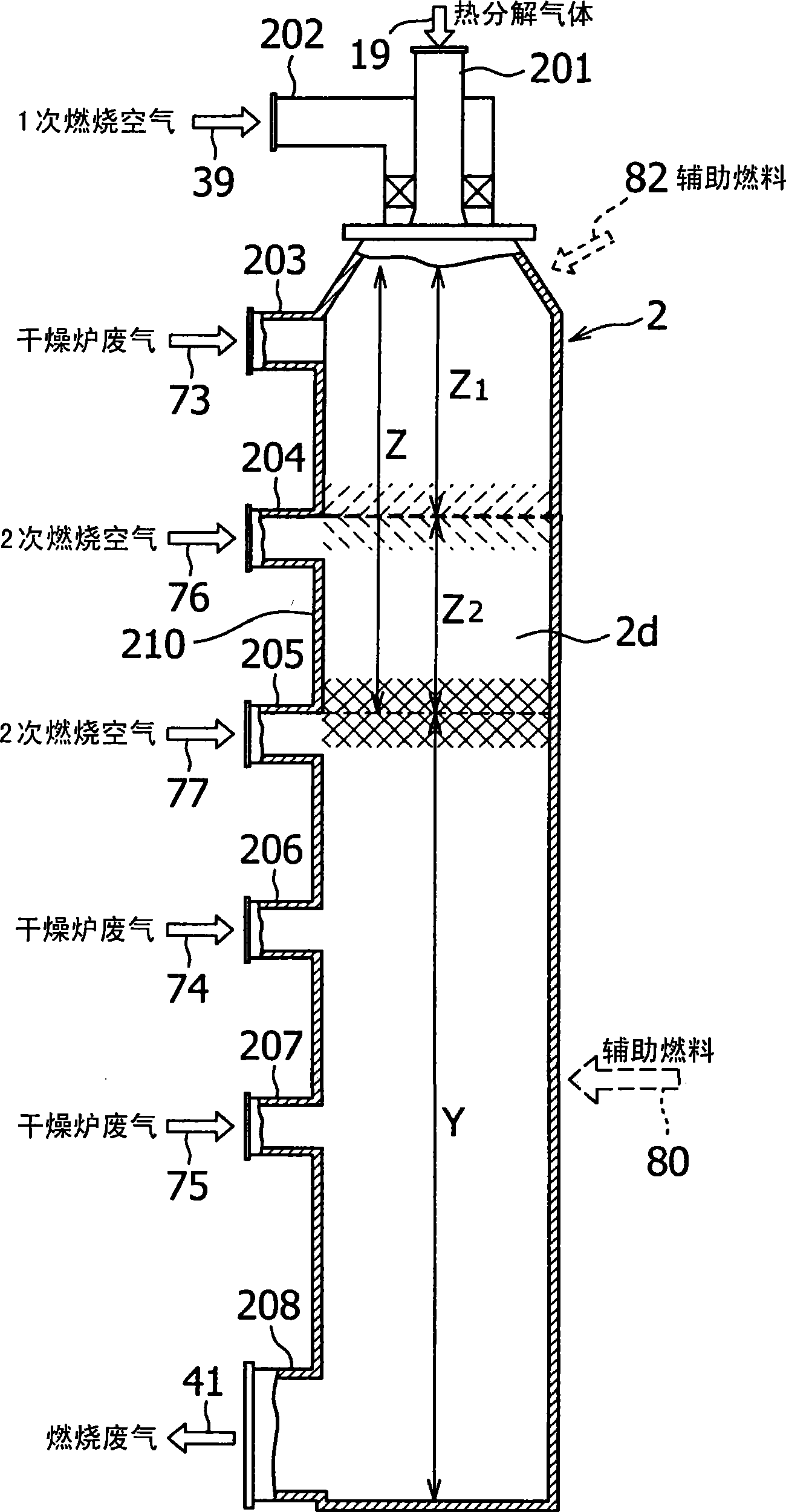

[0091] Trial-manufacture a decomposition gas combustion furnace, and compare the case of inputting dry waste gas and the case of not inputting dry waste gas. When the combustion temperature is about 900°C, the NOx concentration at the outlet is 225ppm without dry exhaust gas, but it drops to 87ppm with dry exhaust gas, and the NO conversion rate decreases from 13.2% to 7.2%. In addition, the NOx concentration is a 12% conversion value.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

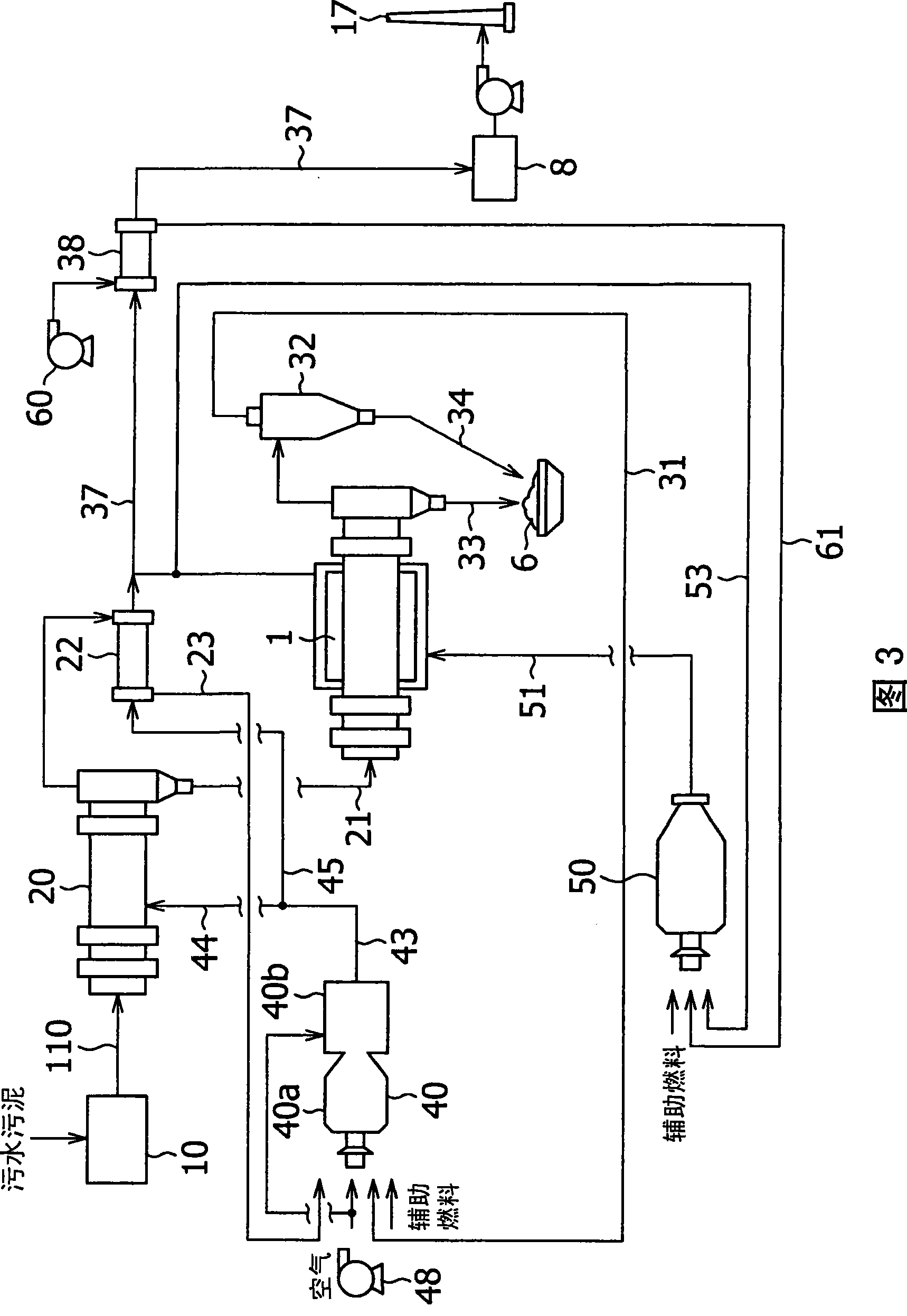

The invention provides a thermal decomposing gas treating device for a high water cut organism carbonizing treatment system. The invention ensures that the thermal decomposing gas burns in a combustion furnace after carbonizing treatment in decomposing gas combustion furnace; the use of auxiliary fuel reaches the lowest limit and a low fuel consumption rate is kept; and besides, the complete combustion can be realized with the reduction of NOx quantity. The thermal decomposing gas treating device is characterized in that the device comprises the following processing steps: introducing the thermal decomposing gas from high water cut organism in carbonizing furnace to the decomposing gas combustion furnace to burn; putting in part of drying waste gas after drying treatment for the first time; providing primary burning gas at the same time to carry on burning treatment under reducing gas environment; providing secondary oxidizing gas to burning gas under reducing gas environment to carry out burning treatment under reducing gas environment; and providing drying waste gas to the burning gas under oxidizing gas environment the second time to carry on final burning treatment.

Description

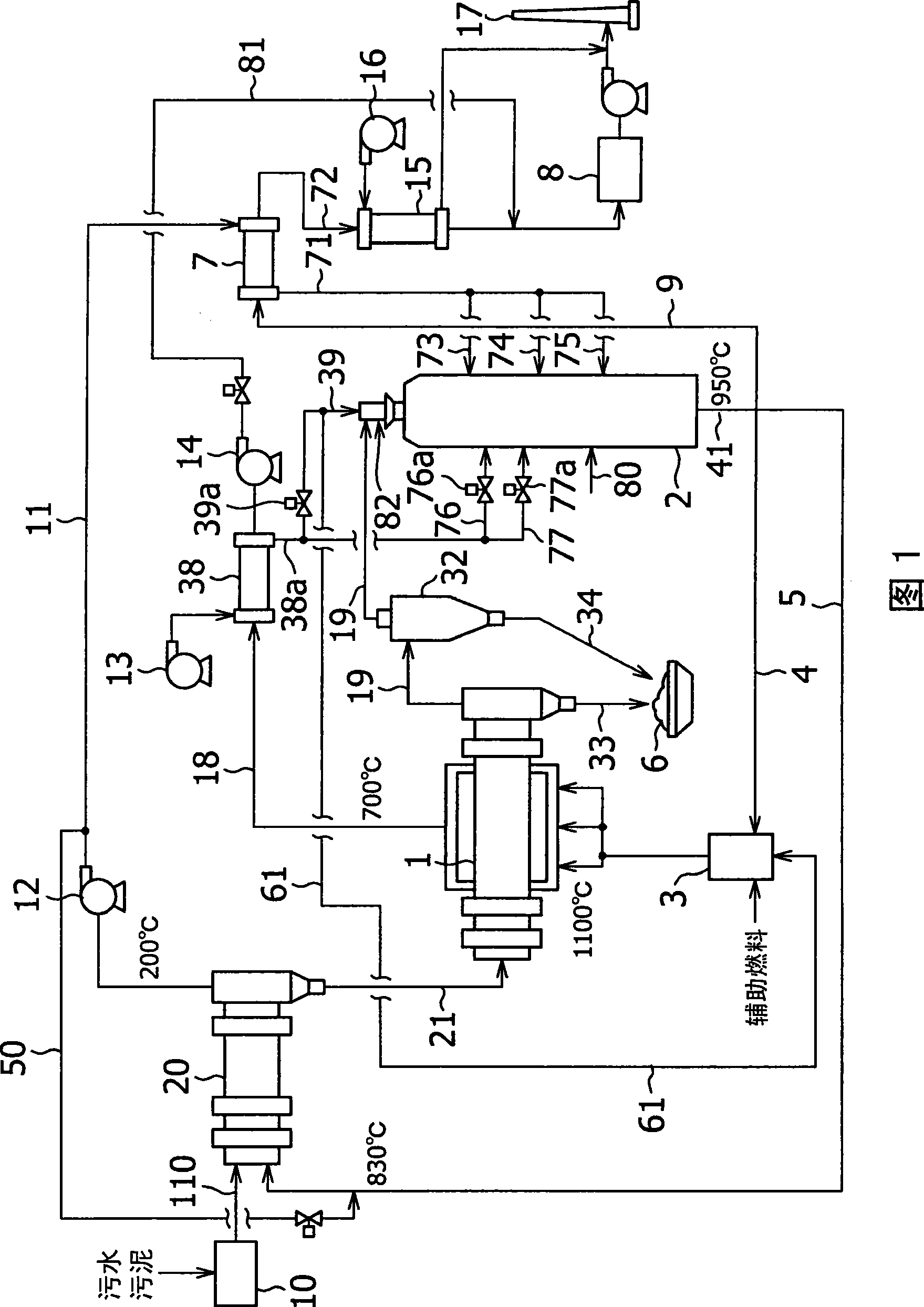

technical field [0001] The invention relates to a thermal decomposition gas treatment method and a device thereof in a carbonization treatment system for treating high-water organic matter such as sludge, food processing residues, animal manure and urine produced in sewage treatment plants and the like. Background technique [0002] In order to carbonize high-moisture organic matter represented by sewage sludge, generally, the raw material, that is, the water-containing organic matter is dried and then carbonized in a carbonization furnace. [0003] Here, as the heat source of the carbonization treatment, combustion exhaust gas obtained by burning the pyrolysis gas generated by the carbonization treatment in the decomposition gas combustion furnace is used. [0004] The invention of Patent Document 1 (Japanese Unexamined Patent Publication No. 2005-199157) related to the applicant's application in this case provides a pyrolysis gas of a carbonization treatment system for hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23G7/06F23L1/00F23L9/00

Inventor 一晃加仓田雅治吉良猛甘利敏奥野卫荒冈

Owner MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com