Fine mask and method of forming mask pattern using the same

A mask pattern and mask technology, which is applied in the photoengraving process of the pattern surface, the original for opto-mechanical processing, optics, etc. Resolution, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

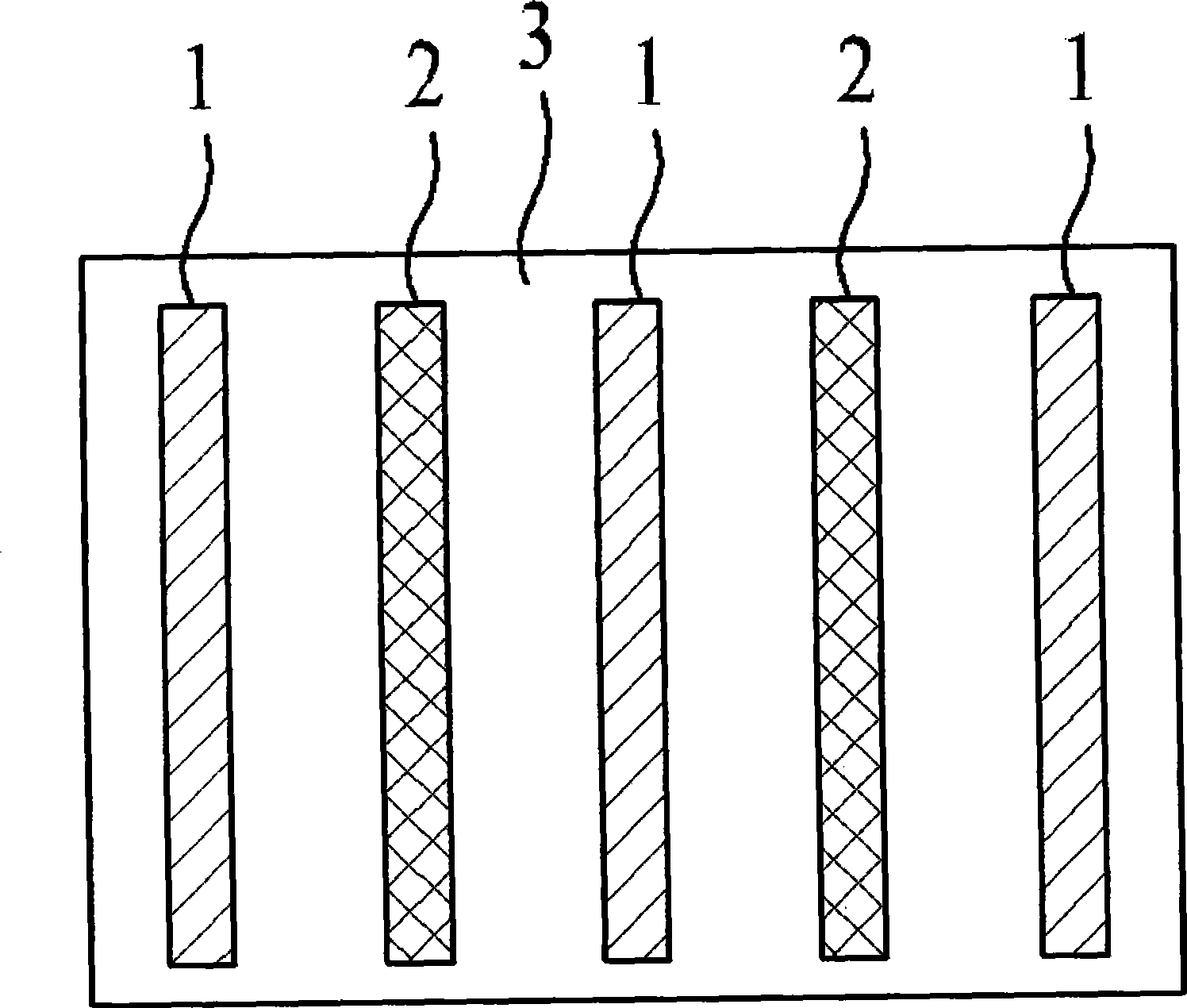

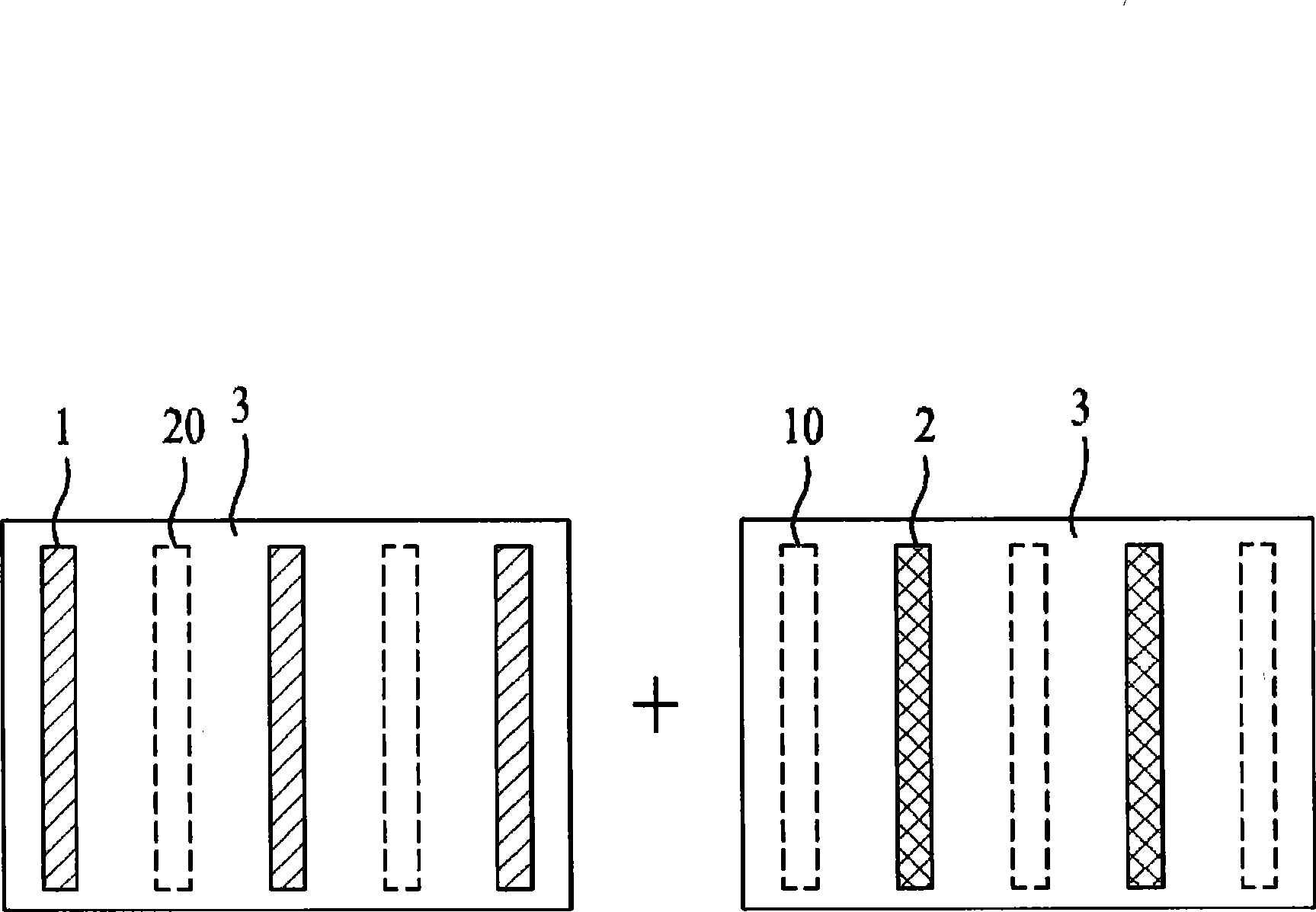

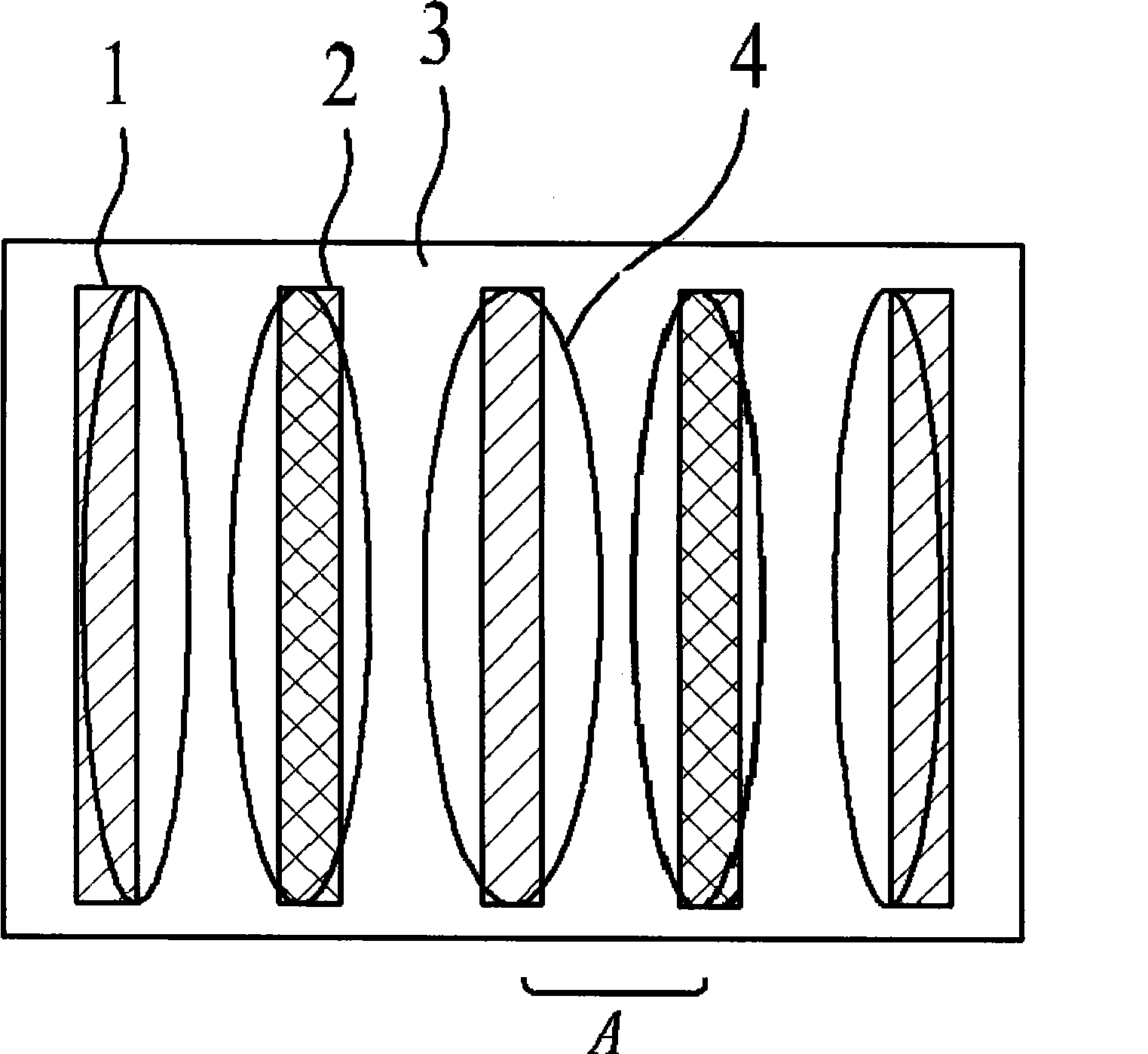

[0024] figure 2 is a schematic diagram of a mask of a double exposure mask according to an embodiment of the present invention. image 3 is a schematic diagram of another mask of a double exposure mask according to an embodiment of the present invention. Figure 4 shows when figure 2 mask as shown and as image 3 The photoresist pattern image obtained when the mask is aligned and exposed is shown.

[0025] figure 2 and image 3 shows two masks, and Figure 4 Two masks are shown optically overlapping each other. In the example, when as figure 2 mask as shown and as image 3 When the masks shown overlap each other, the masks are arranged so that the main patterns of the respective masks do not overlap each other. That is, when figure 2 and image 3 When the two masks in the mask overlap with each other, the positions where the main patterns of the respective masks are located do not overlap with each other.

[0026] In the following description, the figure 2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com