Explosion prevention type electric hot-water bottle

An electric hot water bottle and explosion-proof technology, which is applied to electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of complex structure, failure of protection switch, burst of hot water bottle, etc., to achieve a simple overall structure, ensure normal operation, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

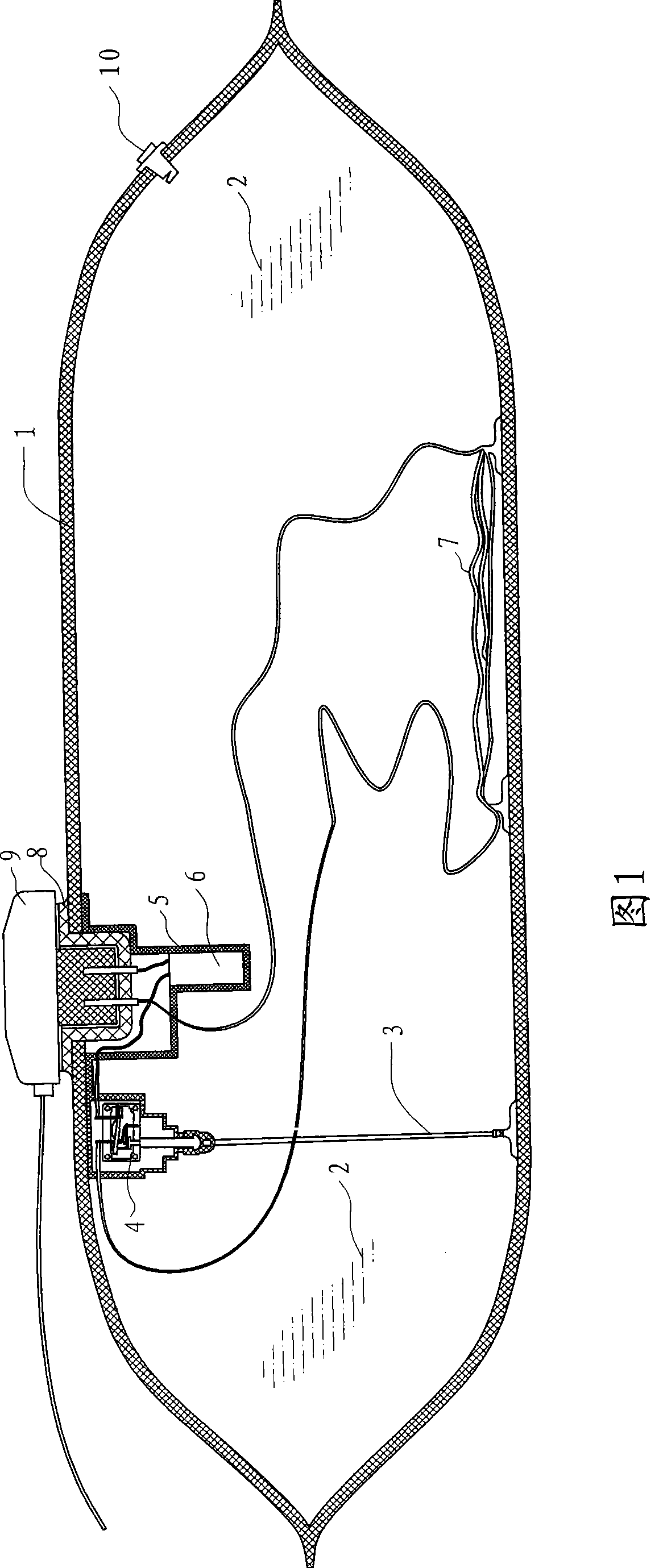

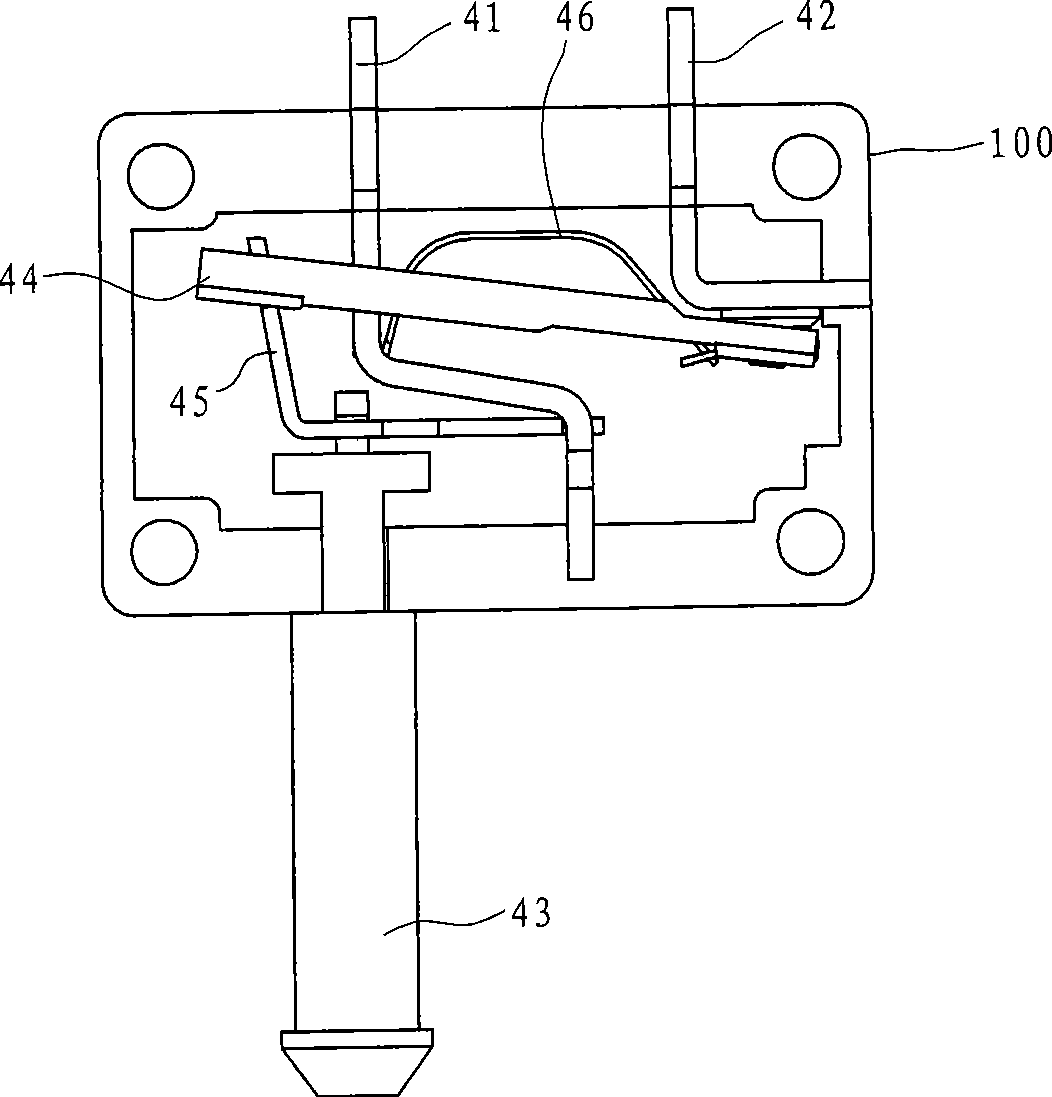

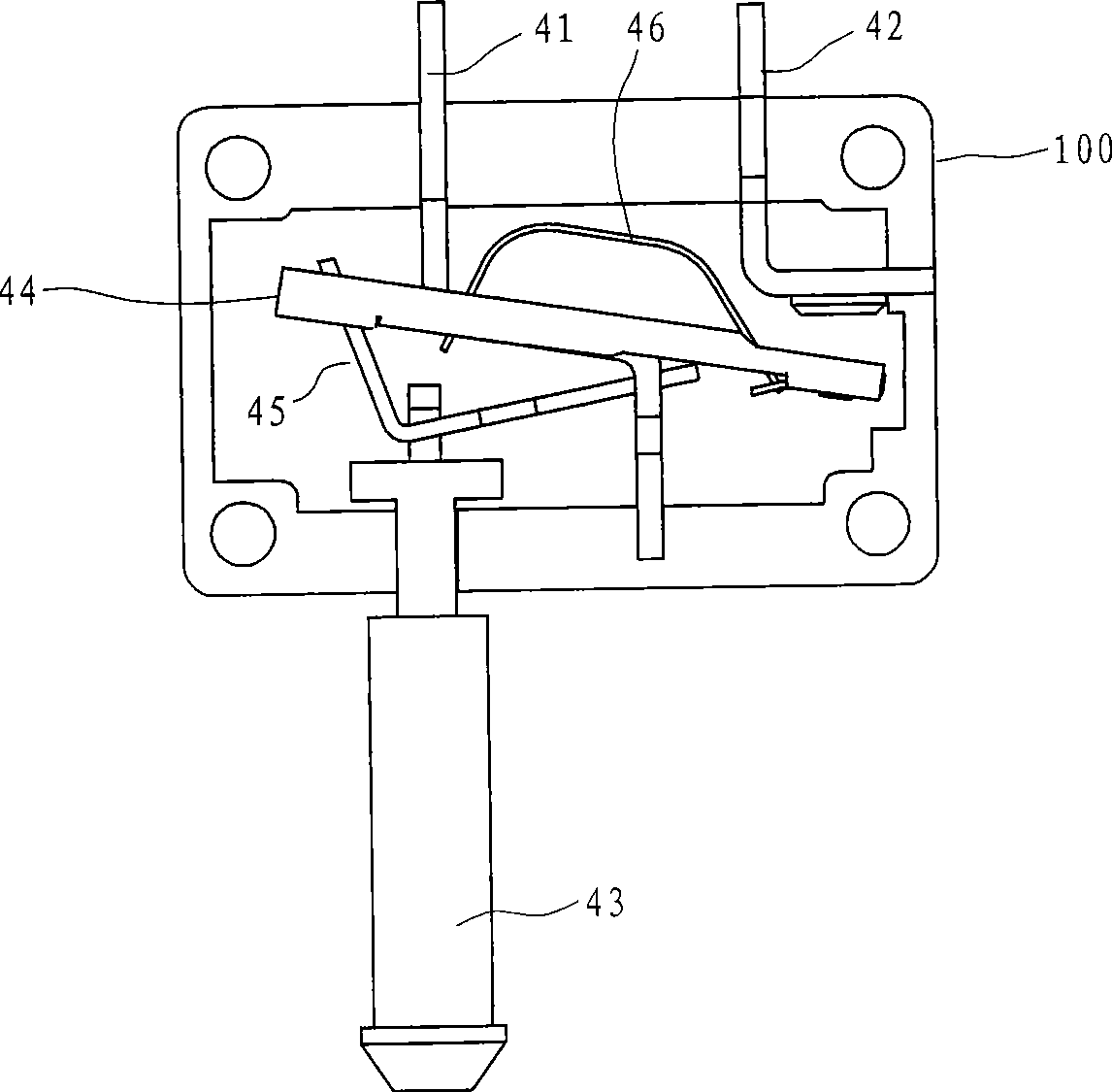

[0029] Embodiment: As shown in FIG. 1, the explosion-proof electric hot water bag in this embodiment includes a closed soft bag body 1, a waterproof casing 5, a temperature controller 6, a liquid 2 serving as a heat storage medium in the bag body 1, and The heating element 7, the bag body 1 is provided with an electric socket 8, a protection switch 4 and a pull cord 3, the protection switch 4 is connected in series on the power circuit of the heating element 7, and the bag body 1 is provided with an electric socket 8 and an electric socket 8 The connected thermostat 6 and the electric socket 8 can be connected with an electric plug 9, and the bag body 1 is also equipped with an exhaust liquid injection hole 10, and the thermostat 6, the protection switch 4 and the electric socket 8 are all located in the waterproof casing 5, The stay cord 3 can drive the pull rod 43 to pull back. The upper end of the stay cord 3 is connected to the outer end of the waterproof casing 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com