Door weatherstrip

A technology for sealing strips and car doors, which is applied to sealing devices, engine seals, vehicle parts, etc. It can solve the problems of reducing sealing performance and inability to absorb height differences, and achieves enhanced conformability, easy elastic deformation, and good conformability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

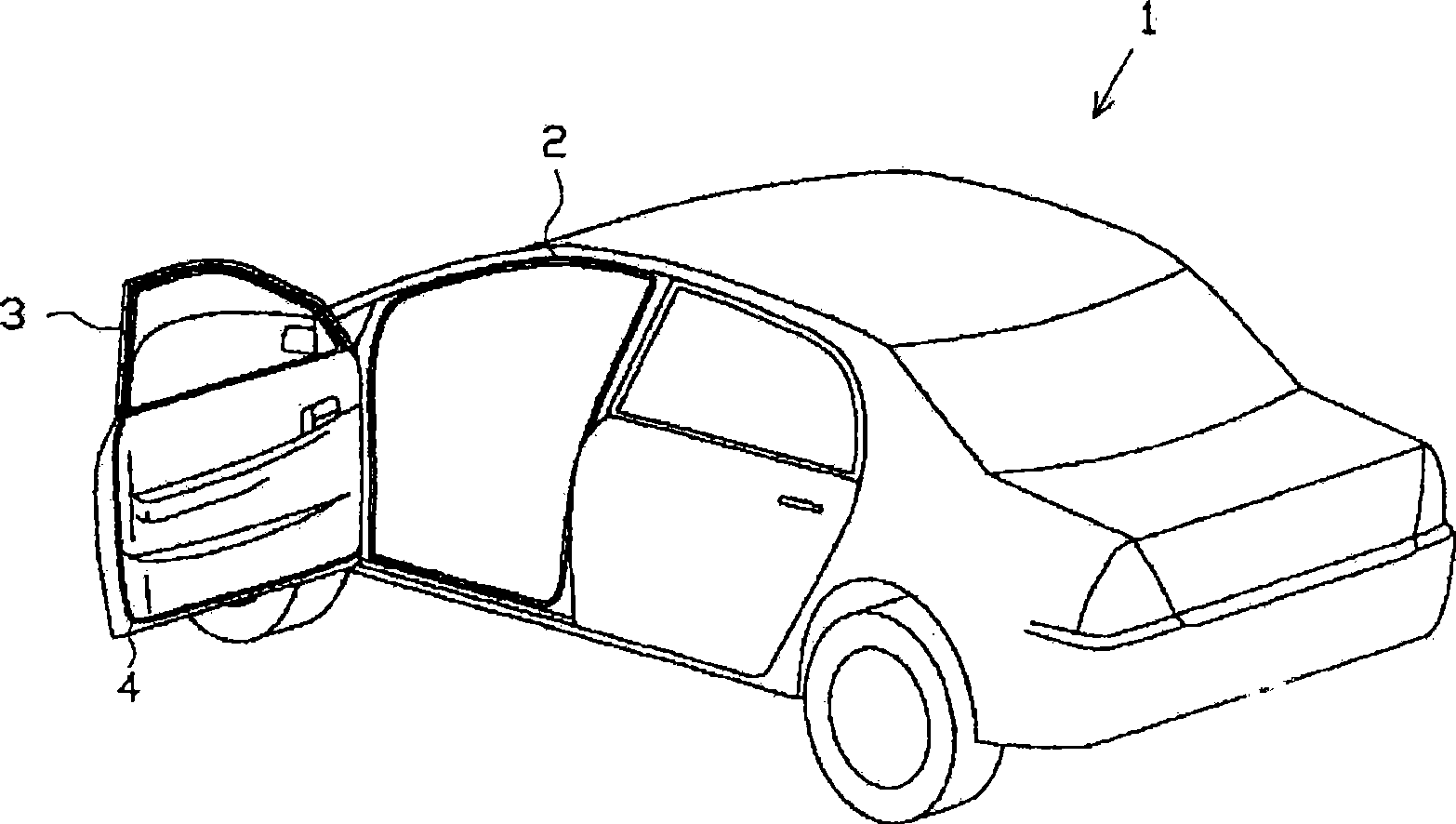

[0034] Next, a first embodiment of a weather strip that is attached around a door periphery of a vehicle (motor vehicle) will be described with reference to the drawings.

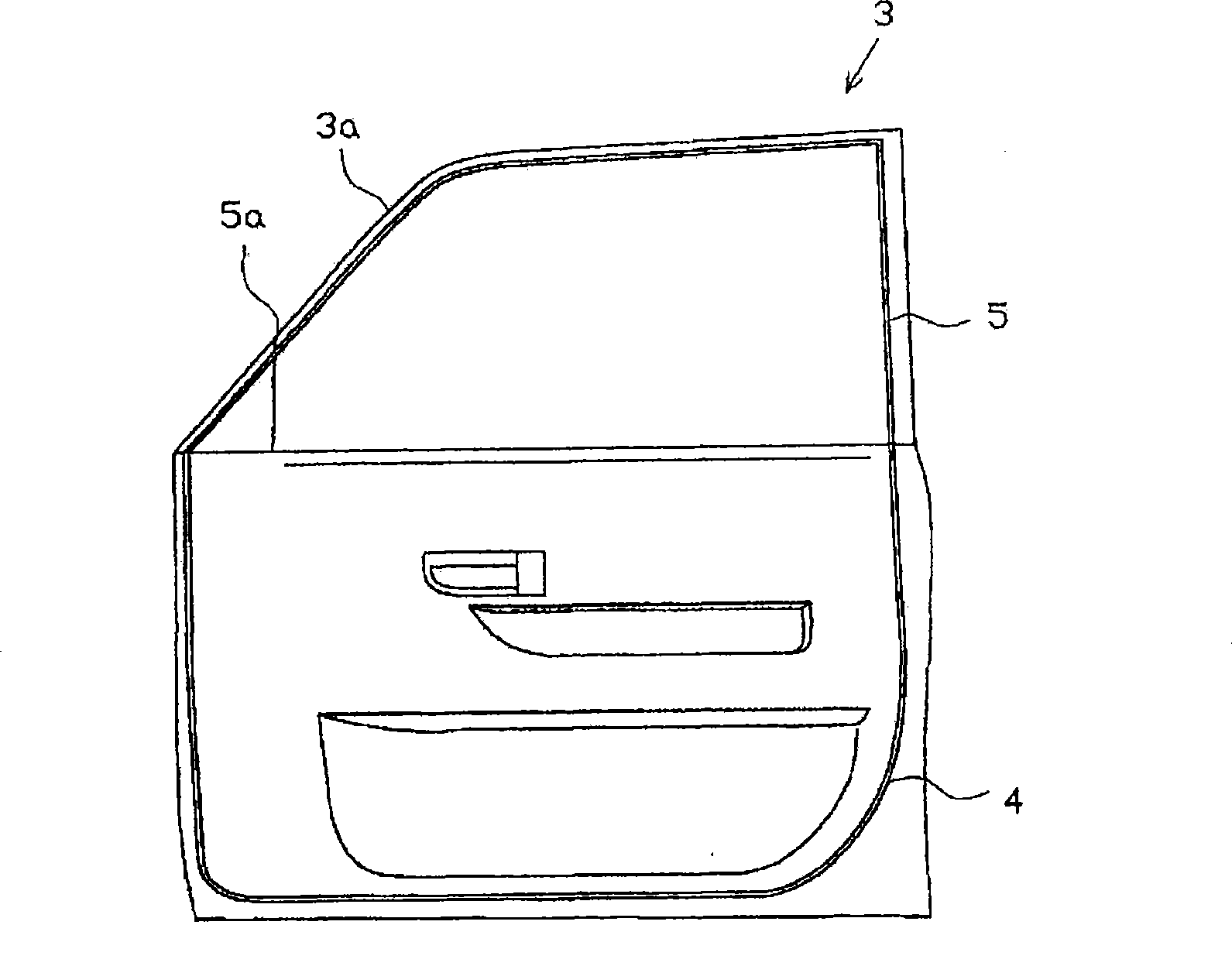

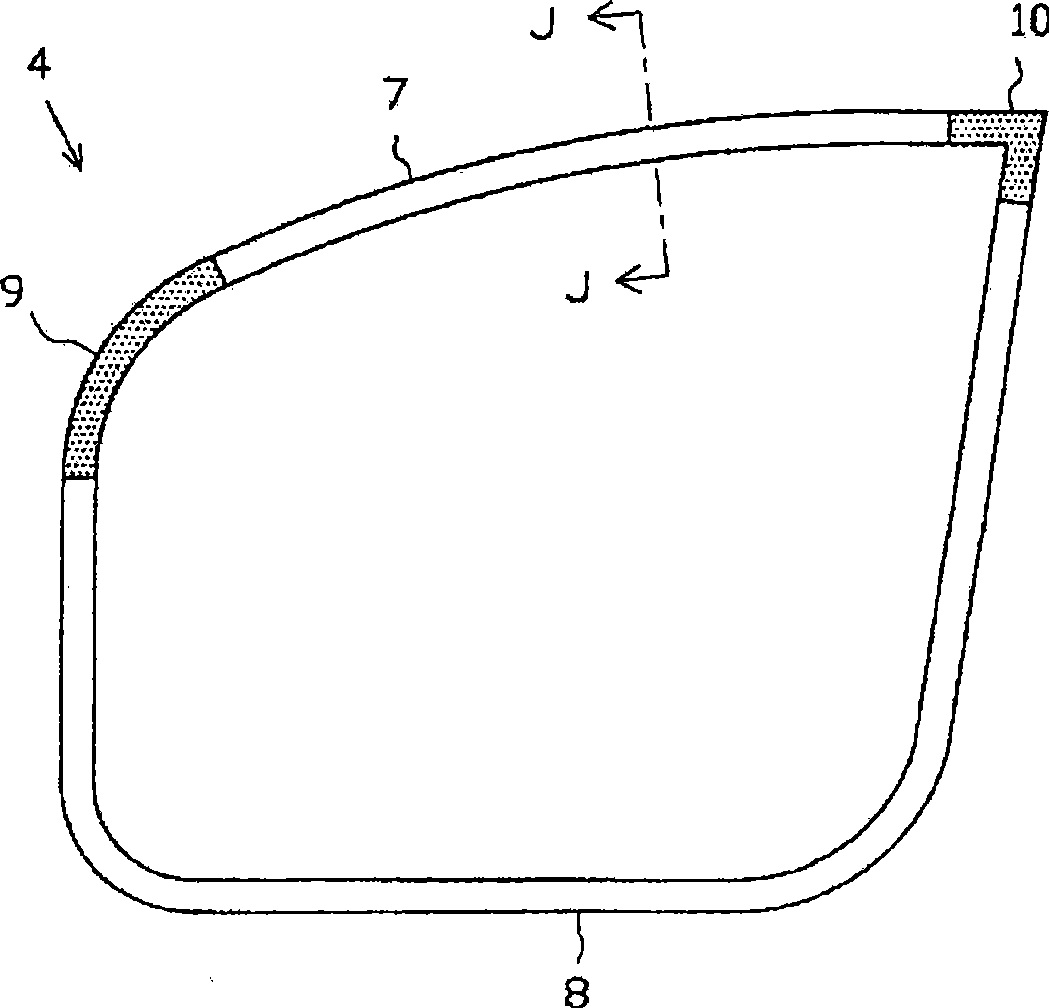

[0035] Such as figure 1 , figure 2 As shown, in the door opening 2 of the motor vehicle 1, a door 3 is provided in an openable and closable manner, and a sealing strip is installed around the periphery of the door 3 . In addition, the door 3 is made of panels such as an inner panel 5 and an outer panel 6 (see Figure 4 ). Therefore, the door panel of the present embodiment is constituted by panel members 5 , 6 .

[0036] Among these panels, the inner panel 5 is formed by welding panels of different thicknesses so that the hinge side ( figure 2 center left) and open side ( figure 2 middle right) with different thicknesses. This is because thick plate parts are used on the hinge side to ensure the rigidity of the hinge side. Therefore, the welding portion 5 a is exposed at the upper edge portion 3 a...

no. 2 approach

[0068] Next, a second embodiment of a weather strip which is installed around a door periphery of a vehicle (motor vehicle) will be described with reference to the drawings.

[0069] Such as Figure 7 , Figure 8 As shown, in the door opening 102 of the motor vehicle 101 , a door 103 is provided in an openable and closable manner, and a weather strip is installed around the periphery of the door 103 . In addition, the door 103 is made of panels such as an inner panel 105 and an outer panel 106 (see Figure 10 ). Therefore, the door panel of the present embodiment is constituted by panel members 105 , 106 .

[0070] Among these panels, the inner panel 105 is formed by welding panels of different thicknesses, and on the hinge side ( Figure 8 center left) and open side ( Figure 8 middle right) with different thicknesses. This is because a thick plate member is used on the hinge side to ensure rigidity on the hinge side. Therefore, the welding portion 105a is exposed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com