Pallet structure and manufacturing method thereof

A manufacturing method and pallet technology, applied to rigid containers, containers, packaging, etc., can solve the problems of complex manufacturing process, insufficient durability, high manufacturing cost, etc., achieve simple manufacturing process, simple pallet structure, and facilitate mass processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

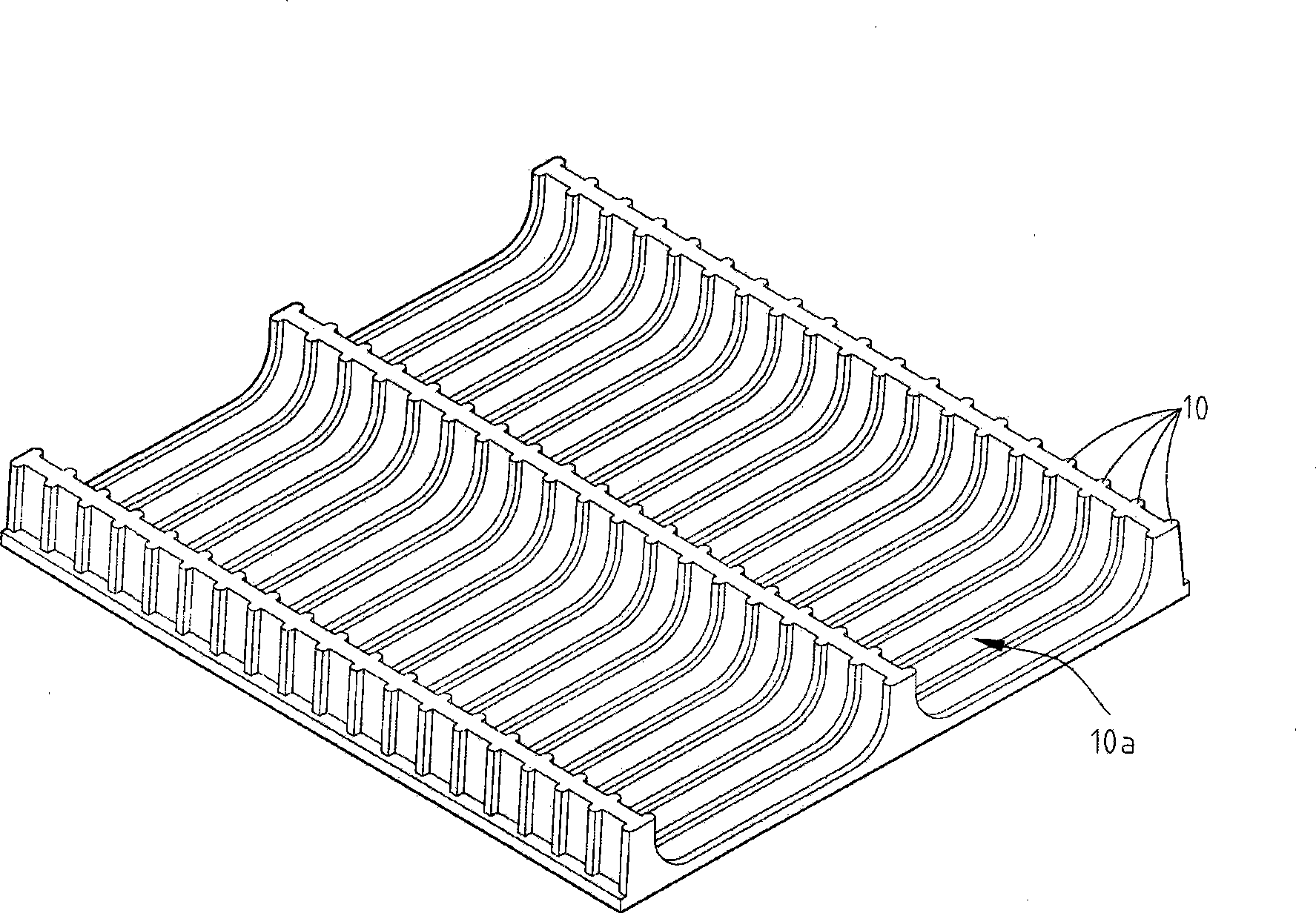

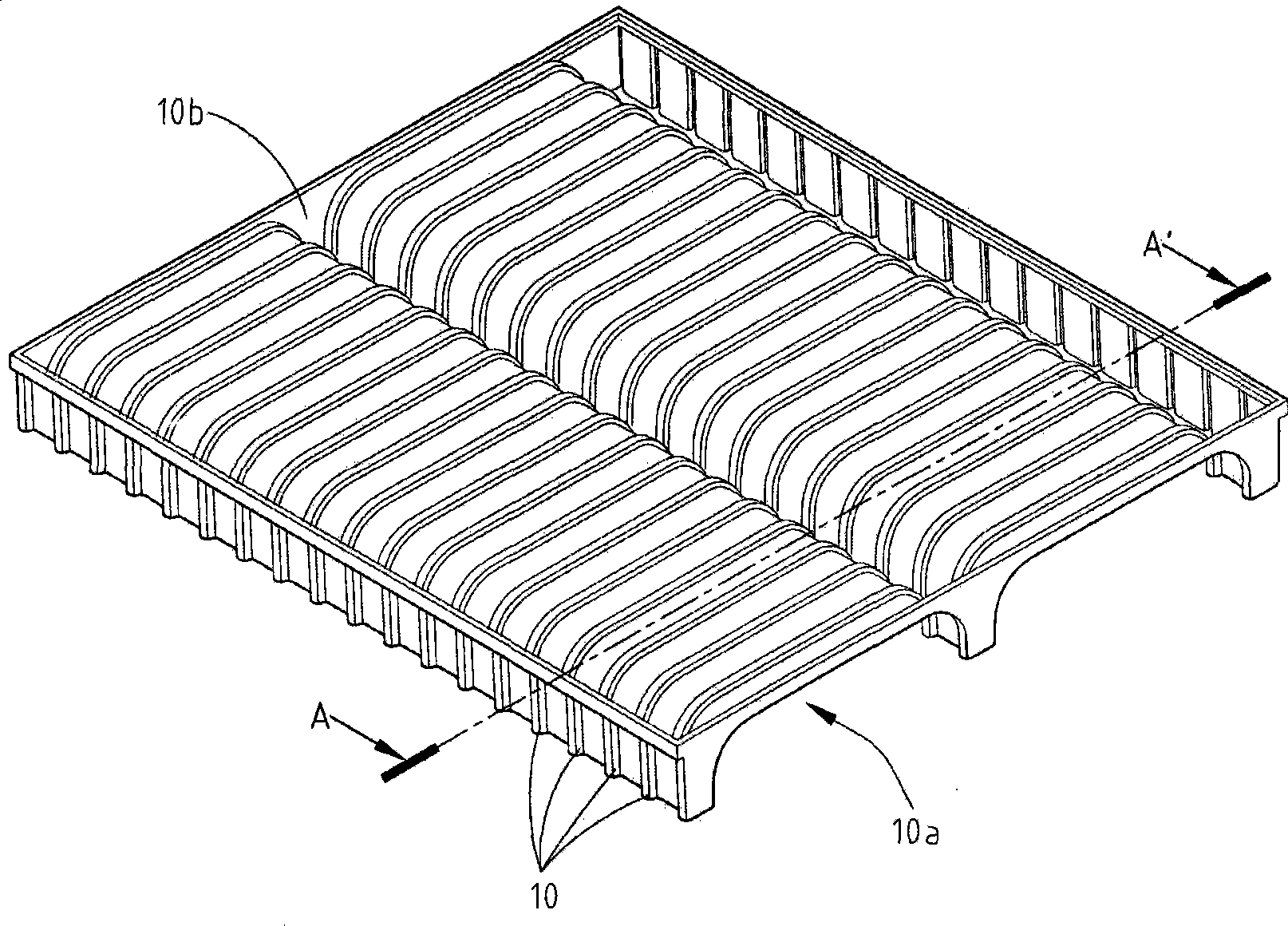

[0023] see Figure 1A-1B , which is a schematic diagram of multiple supports in the pallet structure of the present invention. Such as Figure 1A As shown, among the plurality of supports 10 in the structure of the pallet 5 of the present invention, each support 10 is an inverted U-shaped body with a wide surface, and is tightly combined with each other. Since each support body 10 is an inverted U-shaped body with a wide face, the space 10a called by the two ends of the U-shaped can then be used for the tooth fork 16 of the stacker (such as Figure 3B Shown) in and out, so that the stacker can lift and put down the pallet 5 body and the objects (ie goods) placed on the pallet 5.

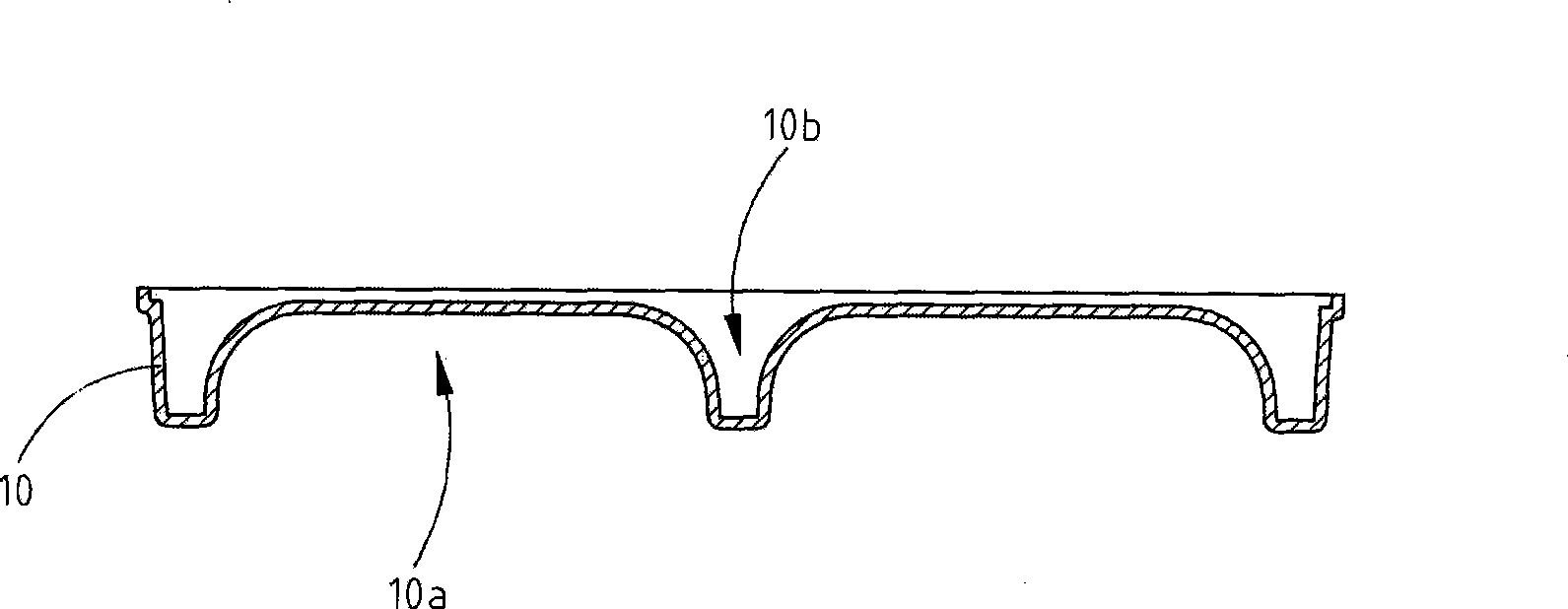

[0024] Such as Figure 1B As shown, when the plurality of support bodies 10 are observed from the back side (that is, the side that does not directly contact the forks 16 of the stacker), it can be observed that the plurality of support bodies 10 have hollows 10b. Obviously, in order to strengthen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com