Gas positive-pressure spraying mixed apparatus of gas engine

A technology of gas engine and gas, which is applied in the field of gas engine gas positive pressure injection and mixing device, which can solve the problems of difficult gas transformation, difficult processing technology, damage of intake pipe, etc., and achieves simple structure, easy maintenance and safe use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

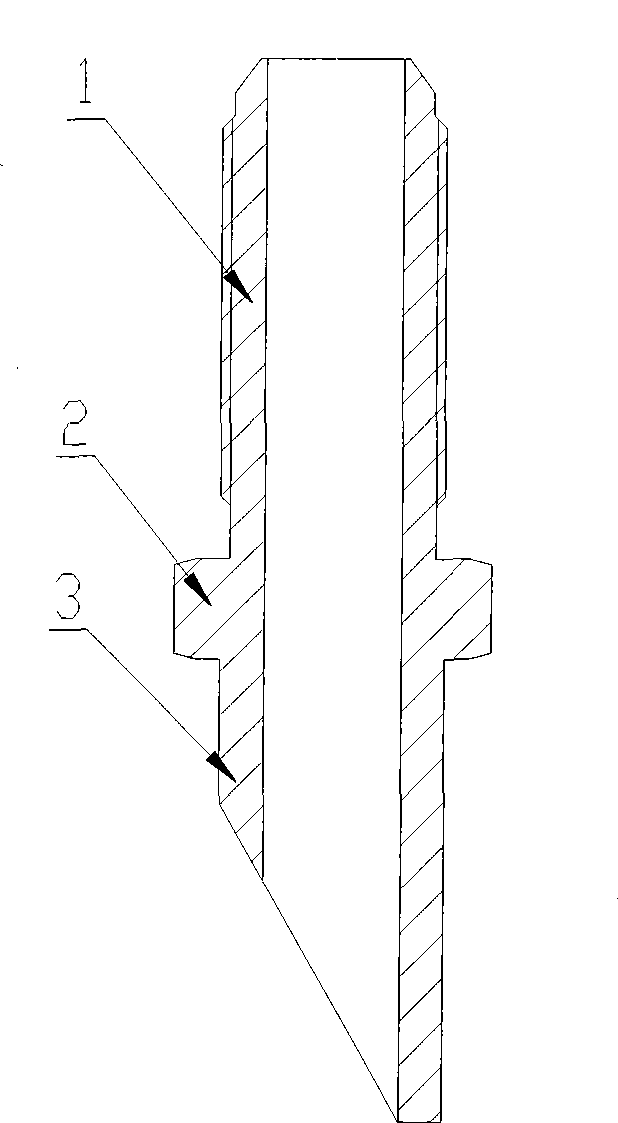

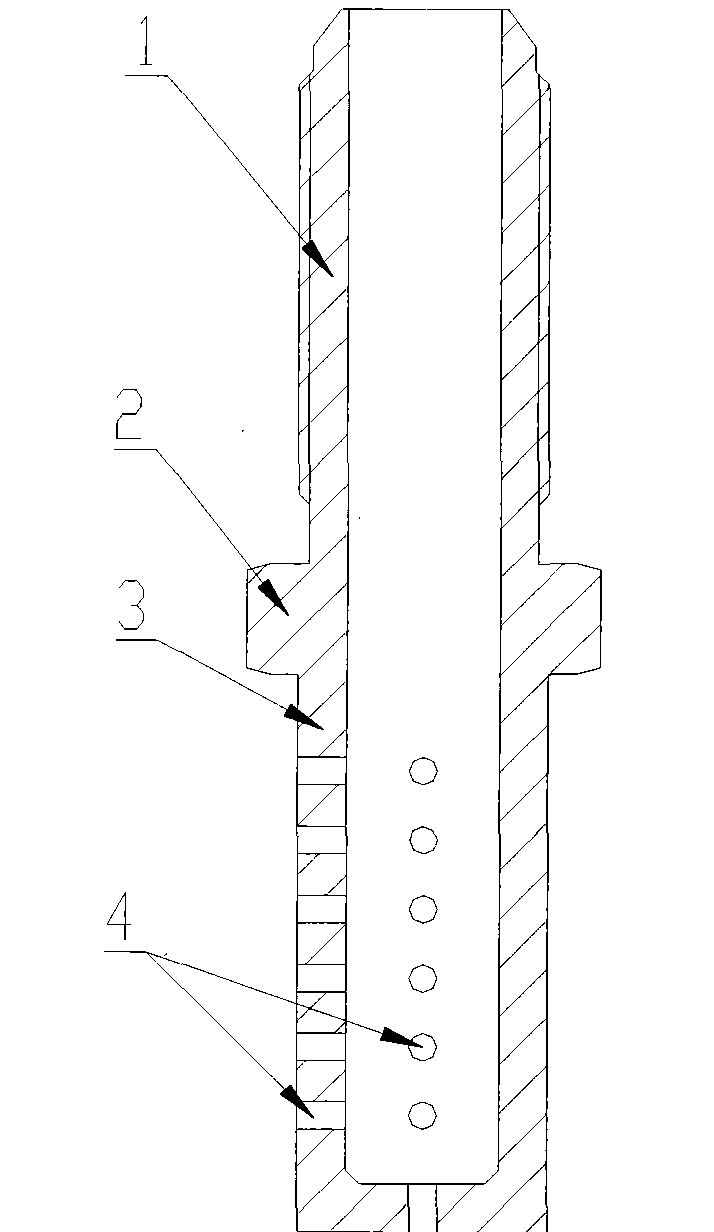

[0013] A gas engine gas positive pressure injection mixing device is characterized in that it is an integral connection structure of a gas inlet part 1, a hexagonal mounting screw part 2 and an intake pipe insertion part 3.

[0014] The air intake pipe insertion part 3 is divided into three rows of small air injection holes 4 in tandem according to a division angle of 90° within 180° of the circumference.

[0015] The number of the air injection small holes 4 is 35, and the sum of the cross-sectional areas of all the small holes is twice the diameter of the gas inlet part (1).

[0016] The angle of the inclined plane of the insertion part 3 of the air inlet pipe is 45°

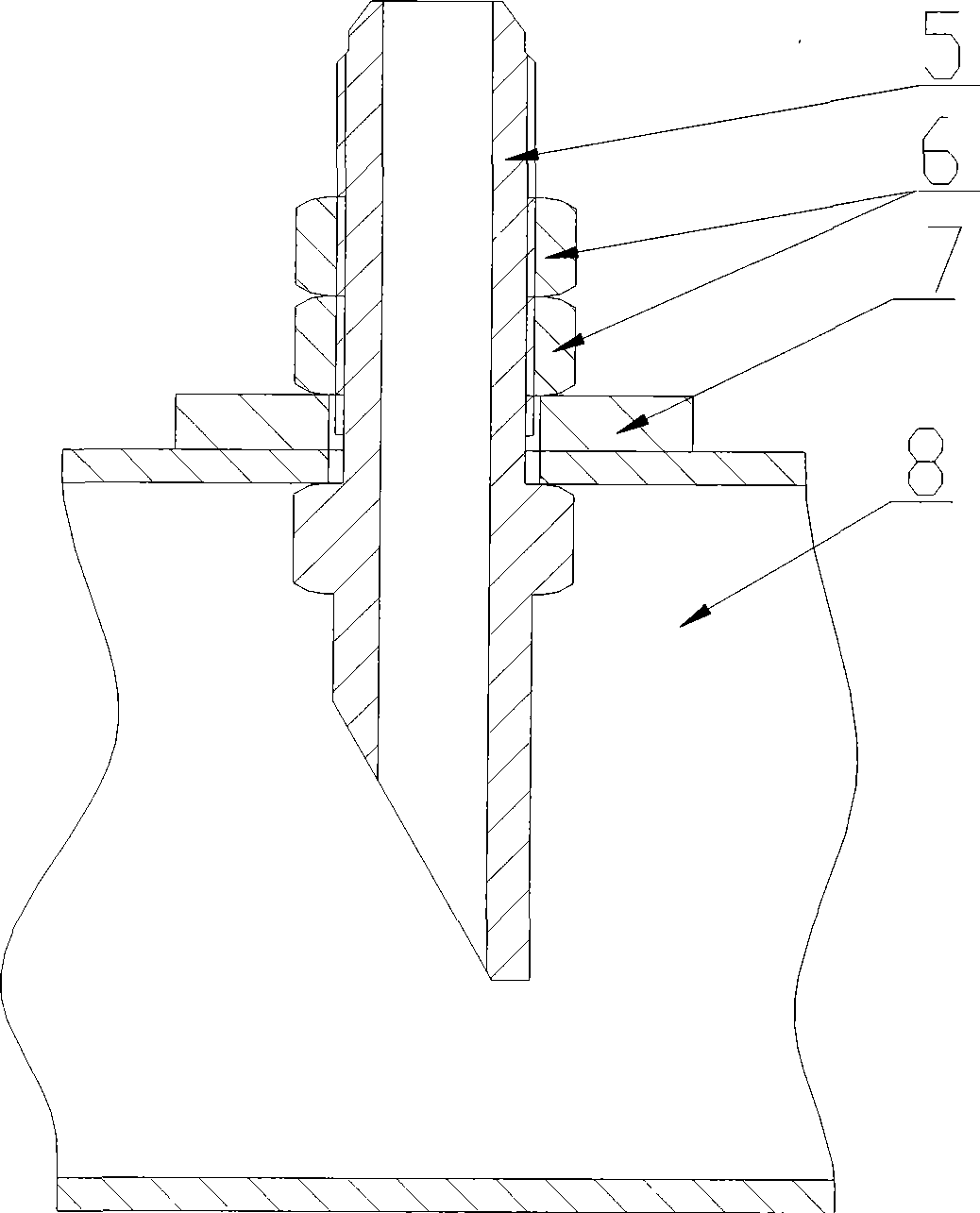

[0017] It is provided with a gas inlet part 1, a hexagonal mounting screw part 2, an inlet pipe insertion part 3, a low-pressure gas outlet and an air injection hole 4, such as figure 2 , during the actual engineering installation, different gas engine gas positive pressure injection and mixing devices can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com