Sound absorption and noise reduction plate special for cooling tower noise reduction and anti-freezing device

An antifreeze device and cooling tower technology, which is applied in the direction of water shower coolers, sound-generating devices, instruments, etc., can solve the problem of small effective sound-absorbing area of the noise-absorbing guide vane, the noise reduction effect cannot reach the noise reduction effect, and the sound-absorbing flow guide The problems such as the inability to adjust the gap between the sheets can be solved, and the effect of noise reduction is remarkable, the wind resistance ability is improved, and the noise reduction effect is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

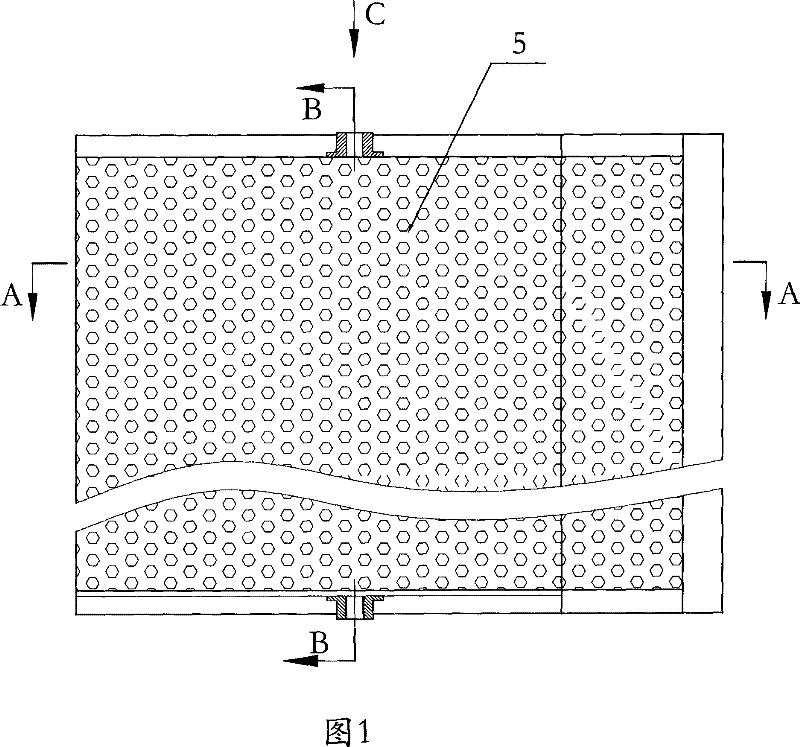

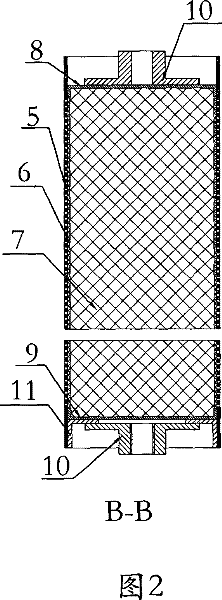

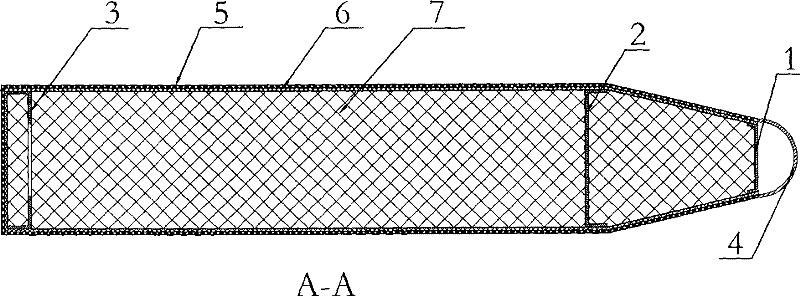

[0014] Embodiment 1: fixedly installed sound-absorbing and noise-reducing panels, such as Figure 1 ~ Figure 4 As shown, it includes a support frame, a small arc air guide 4, a porous plate 5, waterproof non-woven fabric 6, sound-absorbing cotton 7, an upper sealing plate 8, a lower sealing plate 9 and a mounting seat 10. The supporting frame consists of a front supporting plate 1 , the middle support plate 2, the rear support plate 3 and the lower support frame 11, and the front support plate 1, the middle support plate 2 and the rear support plate 3 are all fixed on the lower support frame 11, and the transverse cross-sectional shape of the support frame is a rectangle and a trapezoid combination, the perforated plate 5 is coated on the left and right sides of the support frame, the tail end surface and the trapezoidal side of the outer end, the upper sealing plate 8 and the lower sealing plate 9 are respectively covered on the upper end surface and the lower end surface of t...

Embodiment 2

[0015] Embodiment 2: The rotatable sound-absorbing and noise-reducing board has the same structure as that of Embodiment 1, except that a hole is provided on the mounting seat 10 to cooperate with the revolving pin. The pins are installed on the façade frame, and the sound-absorbing and noise-reducing panels can rotate around the pins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com