Polylactic acid-modified polycarbodiimide compound, polylactic acid resin composition containing same and molded article

A technology of polycarbodiimide and polylactic acid resin, which is applied in the field of polycarbodiimide compounds, can solve problems such as lack of uniformity, achieve excellent hydrolysis resistance, improve mechanical properties, and enhance the effect of entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] The invention will be described below with reference to specific examples. The physical properties described in the examples were measured and evaluated by the following methods.

[0067] (1) Hydrolysis resistance

[0068] The produced pellets of the resin composition were kept for a given time in an atmosphere comprising a temperature of 80° C. and a humidity of 95 RH%. The change in number average molecular weight was measured using GPC (Gel Permeation Chromatography). The hydrolysis resistance was evaluated according to the following criteria:

[0069] ○ (good): The initial number average molecular weight is maintained even after 150 hours have elapsed.

[0070] × (poor): Decomposition proceeded after 150 hours had elapsed, and the initial number average molecular weight could not be maintained.

[0071] (2) Compatibility

[0072] The pellets of the produced resin composition were placed on a slide glass heated to 200°C. After dissolution, the resin was covered...

manufacture example 1

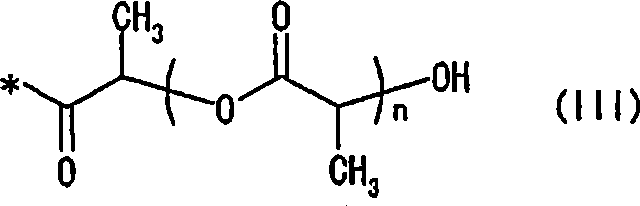

[0077] Production Example 1 (Production 1 of polylactic acid for production of polylactic acid-modified polycarbodiimide; raw material: lactic acid)

[0078] Put L-lactic acid (a primary chemical) in a flask equipped with a stirrer and a cooling tube, and perform a dehydration reaction under reduced pressure at 150° C. for 6 hours, and discharge the generated water from the system. The resulting reaction mass was precipitated using hexane to obtain polylactic acid ((oligomer)) having a number average molecular weight of 300-500. Herein, the number average molecular weight was determined by determining the number of terminal carboxylic acids.

manufacture example 2

[0079] Production Example 2 (Production 2 of polylactic acid for production of polylactic acid-modified polycarbodiimide; raw material: lactide)

[0080] L-lactide (a primary chemical) and 150 ppm of tin octoate (relative to L-lactide) were added to a flask equipped with a stirrer and a cooling tube, and polymerization was performed at 190°C in a nitrogen atmosphere. Adjust the reaction time to obtain polylactic acid with different molecular weights. Its molecular weight, determined by determining the number of terminal carboxylic acids, falls within the range of 1,000-20,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com