Preparation method for zirconium silicate wrapped cadmium sulfide selenide scarlet pigment

A technology of cadmium sulfide selenide and zirconium silicate is applied in the field of preparation of cadmium sulfide selenide red material wrapped with zirconium silicate, which can solve the problems of affecting the sealing effect, long synthesis time, easy deformation of the container, etc., and achieves the loss of color body Small, dense coating layer of pigment, reducing the effect of devitrification activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

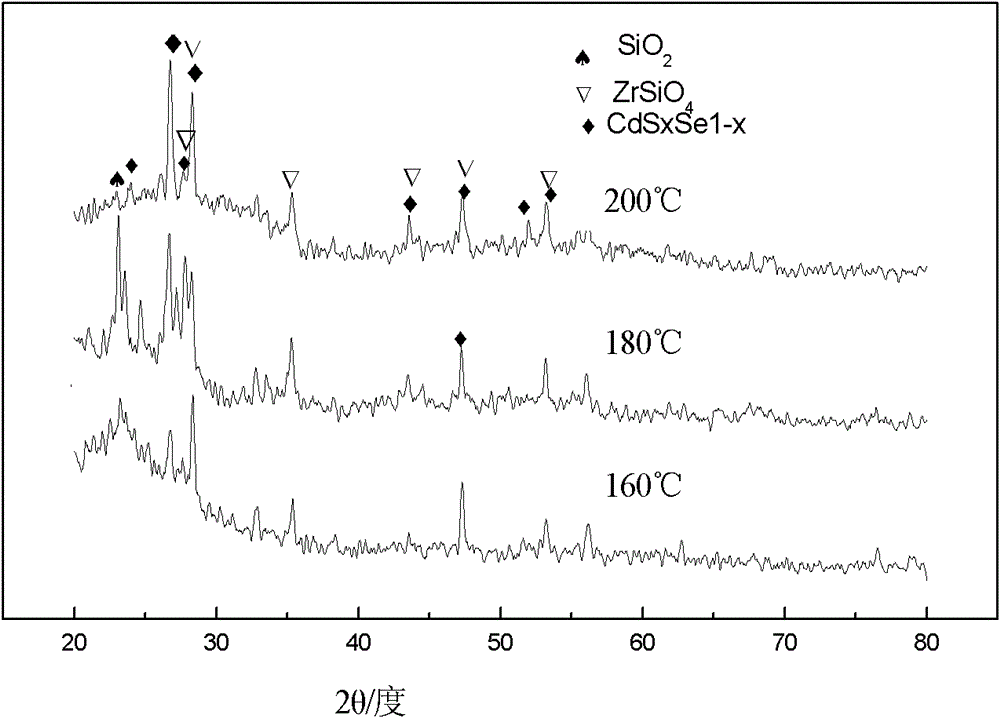

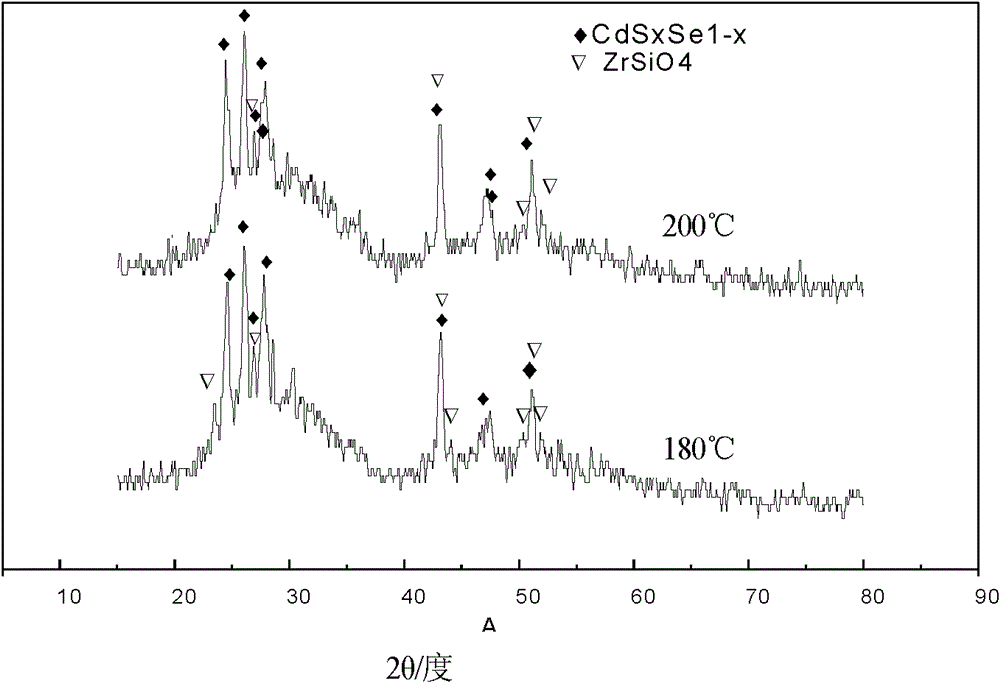

[0014] Embodiment 1: 1) At first, press CdSO 4 :Na 2 The molar ratio of S:Se=1:0.6:0.2 will CdSO 4 and Na 2 S was dissolved in distilled water to make 0.25mol / L CdSO 4 and 0.2mol / L Na 2 S solution, then to Na 2 Add selenium powder in the S solution and stir sodium hydroxide dropwise to get the NaSSe solution after the selenium powder is completely dissolved, wherein Se: NaOH=1: 1 molar ratio, then the described CdSO 4 Solution is added dropwise in NaSSe solution to obtain cadmium sulfur selenide suspension; 2) secondly, press CdSO 4 : ZrOCl 2 :Na 2 SiO 4 =1:2:2.2 molar ratio ZrOCl 2 and Na 2 SiO 4 respectively dissolved in distilled water to form 0.4mol / L ZrOCl 2 and 0.48mol / L Na 2 SiO 4 solution, and then use ammonia or acetic acid to adjust ZrOCl 2 and Na 2 SiO 4 After the pH value of the solution is 5 to 8, mix the two to obtain a mixed sol, add the cadmium sulfoselenide suspension obtained in step 1) dropwise to the mixed sol, and use acetic acid to contro...

Embodiment 2

[0015] Embodiment 2: 1) at first, press CdSO 4 :Na 2 The molar ratio of S:Se=1:0.8:0.25 will CdSO 4 and Na 2S was dissolved in distilled water to make 0.25mol / L CdSO 4 and 0.2mol / L Na 2 S solution, then to Na 2 Add selenium powder in the S solution and stir sodium hydroxide dropwise to get the NaSSe solution after the selenium powder is completely dissolved, wherein Se: NaOH=1: 1 molar ratio, then the described CdSO 4 Solution is added dropwise in NaSSe solution to obtain cadmium sulfur selenide suspension; 2) secondly, press CdSO 4 : ZrOCl 2 :Na 2 SiO 4 =1:2:2.2 molar ratio ZrOCl 2 and Na 2 SiO 4 respectively dissolved in distilled water to form 0.4mol / L ZrOCl 2 and 0.48mol / L Na 2 SiO 4 solution, and then use ammonia or acetic acid to adjust ZrOCl 2 and Na 2 SiO 4 After the pH value of the solution is 5 to 8, mix the two to obtain a mixed sol, add the cadmium sulfoselenide suspension obtained in step 1) dropwise to the mixed sol, and use acetic acid to contro...

Embodiment 3

[0016] Embodiment 3: 1) at first, press CdSO 4 :Na 2 The molar ratio of S:Se=1:0.7:0.3 will CdSO 4 and Na 2 S was dissolved in distilled water to make 0.25mol / L CdSO 4 and 0.2mol / L Na 2 S solution, then to Na 2 Add selenium powder in the S solution and stir sodium hydroxide dropwise to get the NaSSe solution after the selenium powder is completely dissolved, wherein Se: NaOH=1: 1 molar ratio, then the described CdSO 4 Solution is added dropwise in NaSSe solution to obtain cadmium sulfur selenide suspension; 2) secondly, press CdSO 4 : ZrOCl 2 :Na 2 SiO 4 =1:2:2.2 molar ratio ZrOCl 2 and Na 2 SiO 4 respectively dissolved in distilled water to form 0.4mol / L ZrOCl 2 and 0.48mol / L Na 2 SiO 4 solution, and then use ammonia or acetic acid to adjust ZrOCl 2 and Na 2 SiO 4 After the pH value of the solution is 5 to 8, mix the two to obtain a mixed sol, add the cadmium sulfoselenide suspension obtained in step 1) dropwise to the mixed sol, and use acetic acid to contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com