Calcium-aluminum-silicon-based ceramic material for high-density packaging and preparation method thereof

A ceramic material, high-density technology, applied in the field of electronic ceramic materials, can solve the problems of unspecified thermal expansion coefficient and flexural strength, high production cost, high energy consumption, etc. low cost effect

Inactive Publication Date: 2020-10-02

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Ceramic ball grid array package structure (CBGA) is widely used in high-density packaging, but the thermal mismatch problem will occur when the ceramic package module is installed on the PCB through ball planting technology; therefore, a high thermal expansion coefficient, high bending strength and low Dielectric constant packaging materials, in order to meet the urgent needs of high-density packaging

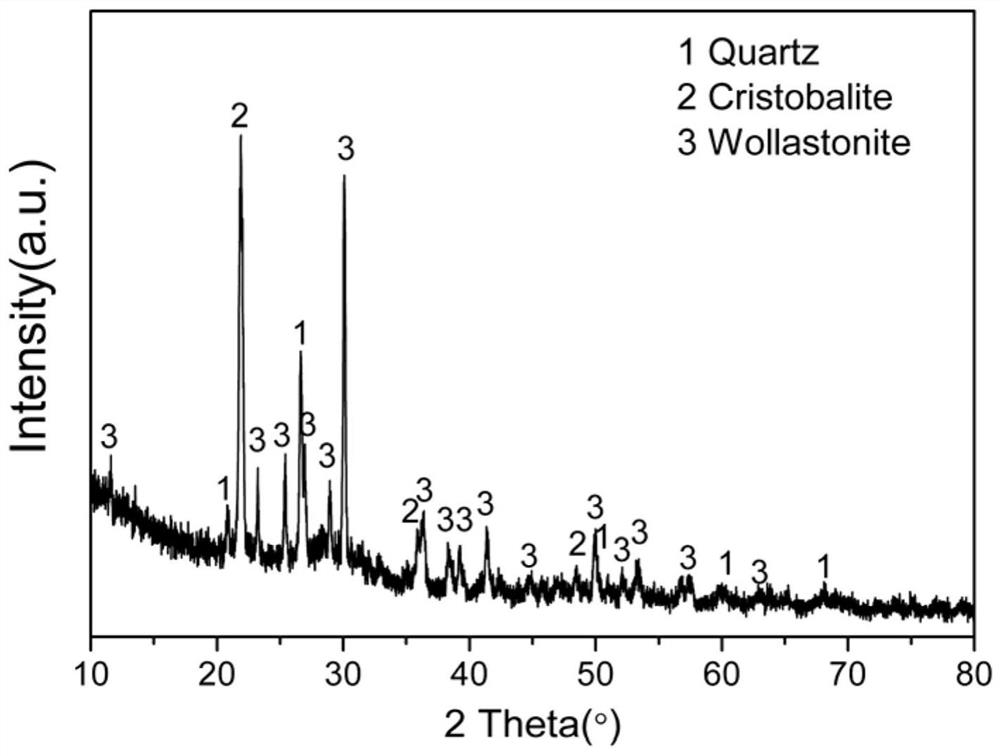

[0003] In recent years, glass-ceramics has received extensive attention and research. For example, the magnesium-aluminum-silicon system has cordierite as the main crystal phase, and its thermal expansion coefficient is 2 o 3 The content of SiO is 95-96%. 2 The content of CaO is 0.6-1.5%, the content of CaO is 0.6-1.5%, the content of CoO is 0.5-1.5%, the dielectric constant of this material is 6-7, and the dielectric loss is ≤0.0003; Indicate the coefficient of thermal expansion and flexural strength, which are two important indicators to measure the thermal and mechanical properties of the substrate material; in addition, the melting temperature of the material reaches 1400-1600°C, which consumes a lot of energy during the preparation process and the production cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

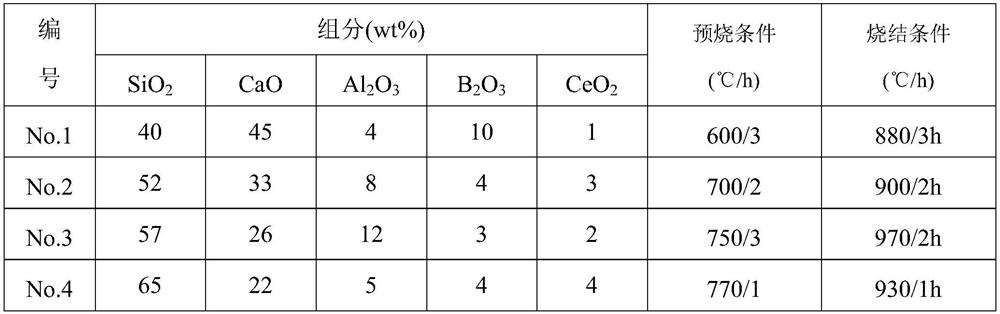

[0020] The present invention is further described below in conjunction with specific examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Login to View More

Abstract

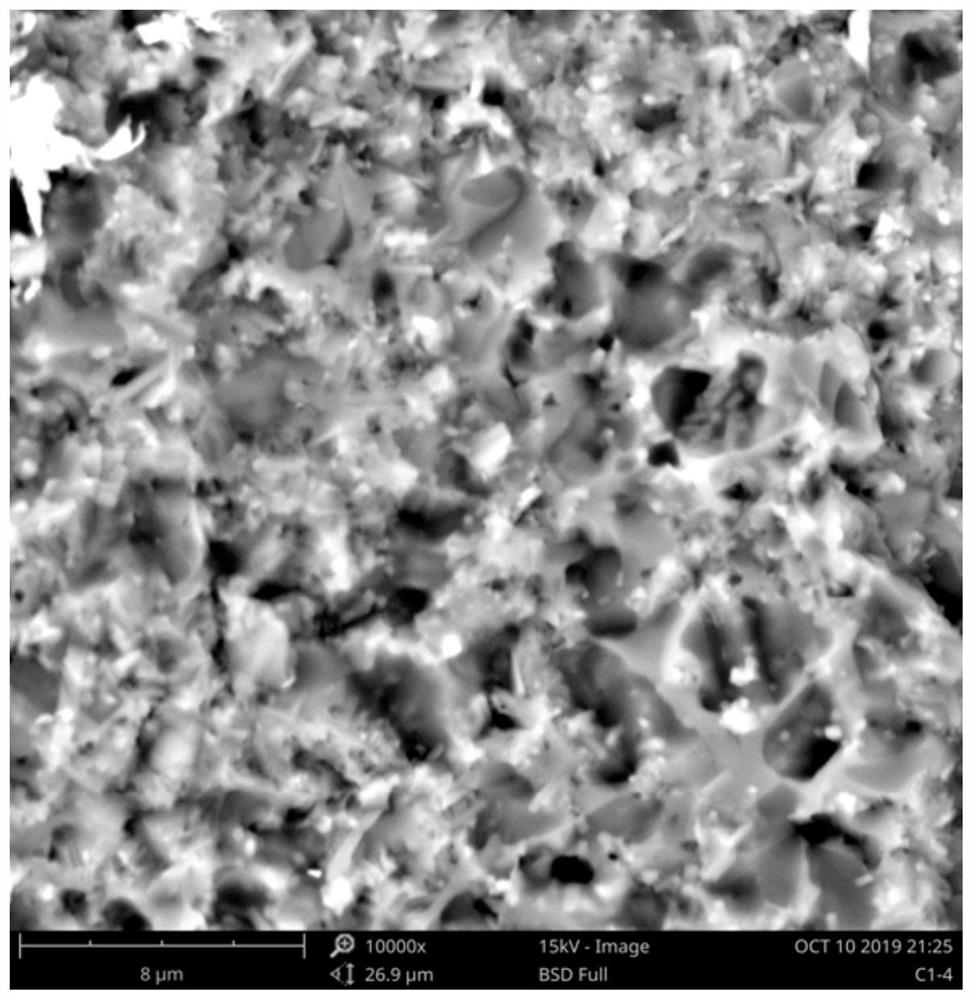

The invention belongs to the technical field of electronic ceramic materials, particularly provides a calcium-aluminum-silicon-based ceramic material for high-density packaging and a preparation method thereof, and aims to solve the problem of thermal mismatch between a ceramic substrate and a PCB under high-density packaging. The calcium-aluminum-silicon-based ceramic material comprises the following components in percentage by weight: 4 to 15 percent of Al2O3, 2 to 10 percent of B2O3, 20 to 50 percent of CaO, 40 to 70 percent of SiO2 and 1 to 5 percent of CeO2. The calcium-aluminum-silicon-based ceramic material has stable and excellent performance, has a low dielectric constant and low dielectric loss, and is beneficial to efficient transmission of signals; due to high bending strength(158-205 MPa) and high Young's modulus (69-72 GPa), enough stable support protection is provided for the chip; the high thermal expansion coefficient (10.3-12.4 ppm / DEG C) and the PCB reach a proper matching degree, the thermal stress between materials is reduced, and the service life of the chip is prolonged; moreover, the substrate material is relatively low in preparation cost, relatively simple in process and stable in performance, and completely meets the requirement of high-density packaging.

Description

technical field [0001] The invention belongs to the technical field of electronic ceramic materials, in particular relates to ceramic materials with a high thermal expansion coefficient, and specifically provides a calcium-aluminum-silicon-based ceramic material for high-density packaging and a preparation method thereof. Background technique [0002] At present, ceramic packaging materials are mainly Al 2 o 3 , its advantages are good moisture resistance, high mechanical strength, high thermal conductivity, relatively mature production and processing technology. Ceramic ball grid array package structure (CBGA) is widely used in high-density packaging, but the thermal mismatch problem will occur when the ceramic package module is installed on the PCB through ball planting technology; therefore, a high thermal expansion coefficient, high bending strength and low Dielectric constant packaging materials, in order to meet the urgent needs of high-density packaging. [0003] I...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/22C04B35/14C04B35/622

CPCC04B35/14C04B35/22C04B35/622C04B2235/3217C04B2235/3229C04B2235/3409C04B2235/96C04B2235/9607

Inventor 李波赵翔浔高陈熊

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com