Lithium transition metal-based compound powder for positive electrode material in lithium rechargeable battery, method for manufacturing the powder, spray dried product of the powder, firing precursor

A lithium secondary battery, lithium transition metal technology, applied in battery electrodes, circuits, electric vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0819] Weigh Li 2 CO 3 , Ni(OH) 2 , Mn 3 o 4 , the molar ratio is Li:Ni:Mn=1.267:0.250:0.583, after mixing, add pure water to prepare slurry. While stirring the slurry, the solid components in the slurry were pulverized to a median particle size of 0.16 μm with a circulating medium agitation type wet pulverizer.

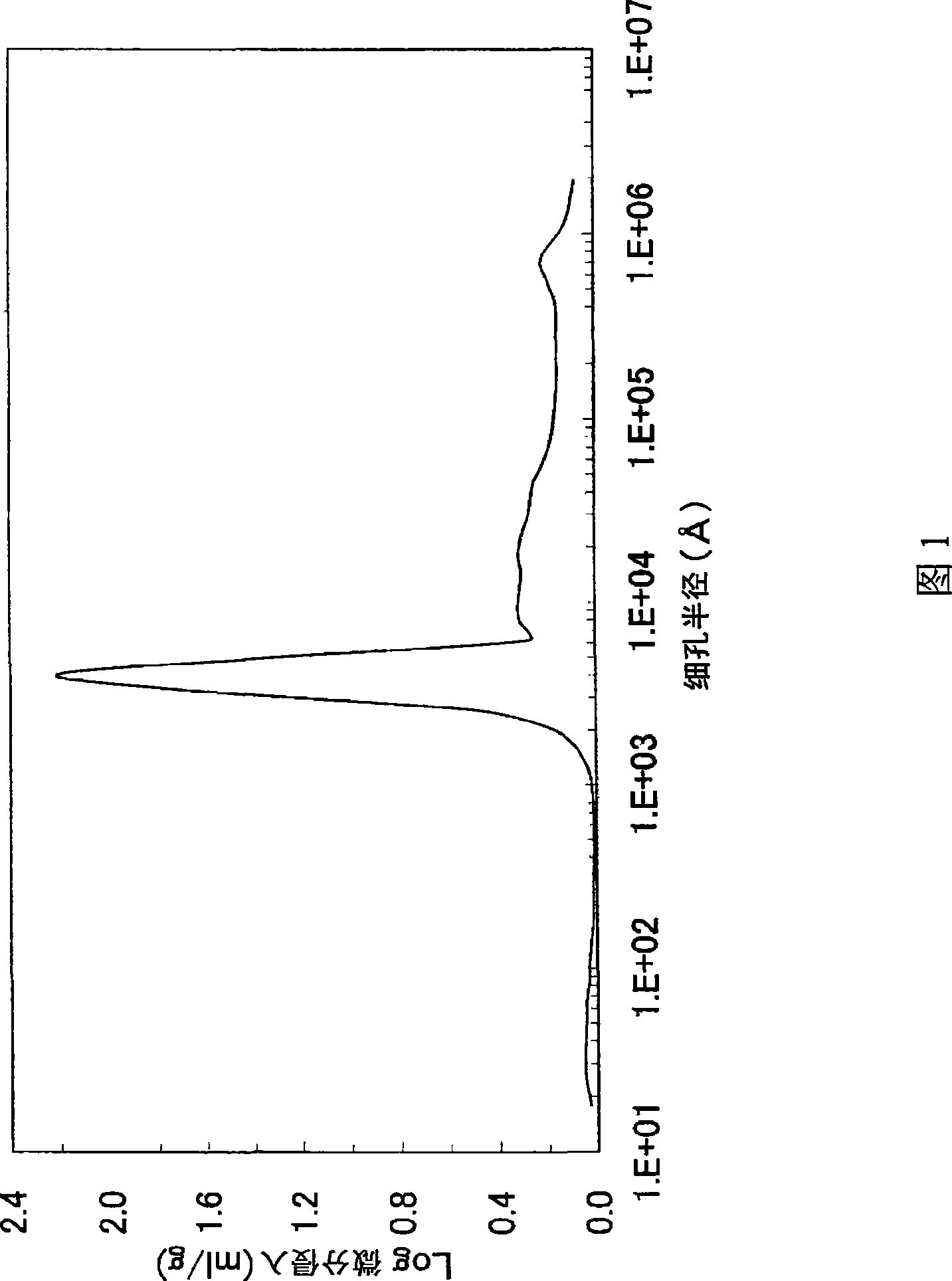

[0820] Put about 15 g of the granular powder obtained by spray-drying the slurry with a spray dryer into an alumina crucible, and calcine it at 950°C for 12 hours in an air atmosphere (heating rate 5°C / min). , crushed to obtain a volume resistivity of 3.7×10 6 Ω·cm, the carbon content is 0.092% by weight, and the composition is Li 1.088 (Li0.167 Ni 0.254 mn 0.579 )O 2 The lithium nickel manganese composite oxide (x=0.167, y=0, z=0.088). Its average primary particle size is 0.2 μm, median particle size is 1.7 μm, 90% cumulative particle size (hereinafter, sometimes also referred to as D 90 ) is 3.6μm, the bulk density is 0.8g / cc, and the BET specific surfac...

Embodiment 2

[0822] Weigh Li 2 CO 3 , Ni(OH) 2 , Mn 3 o 4 , the molar ratio is Li:Ni:Mn=1.267:0.250:0.583, after mixing, add pure water to prepare slurry. While stirring the slurry, the solid content in the slurry was pulverized to a median particle size of 0.16 μm with a circulating medium agitation type wet pulverizer.

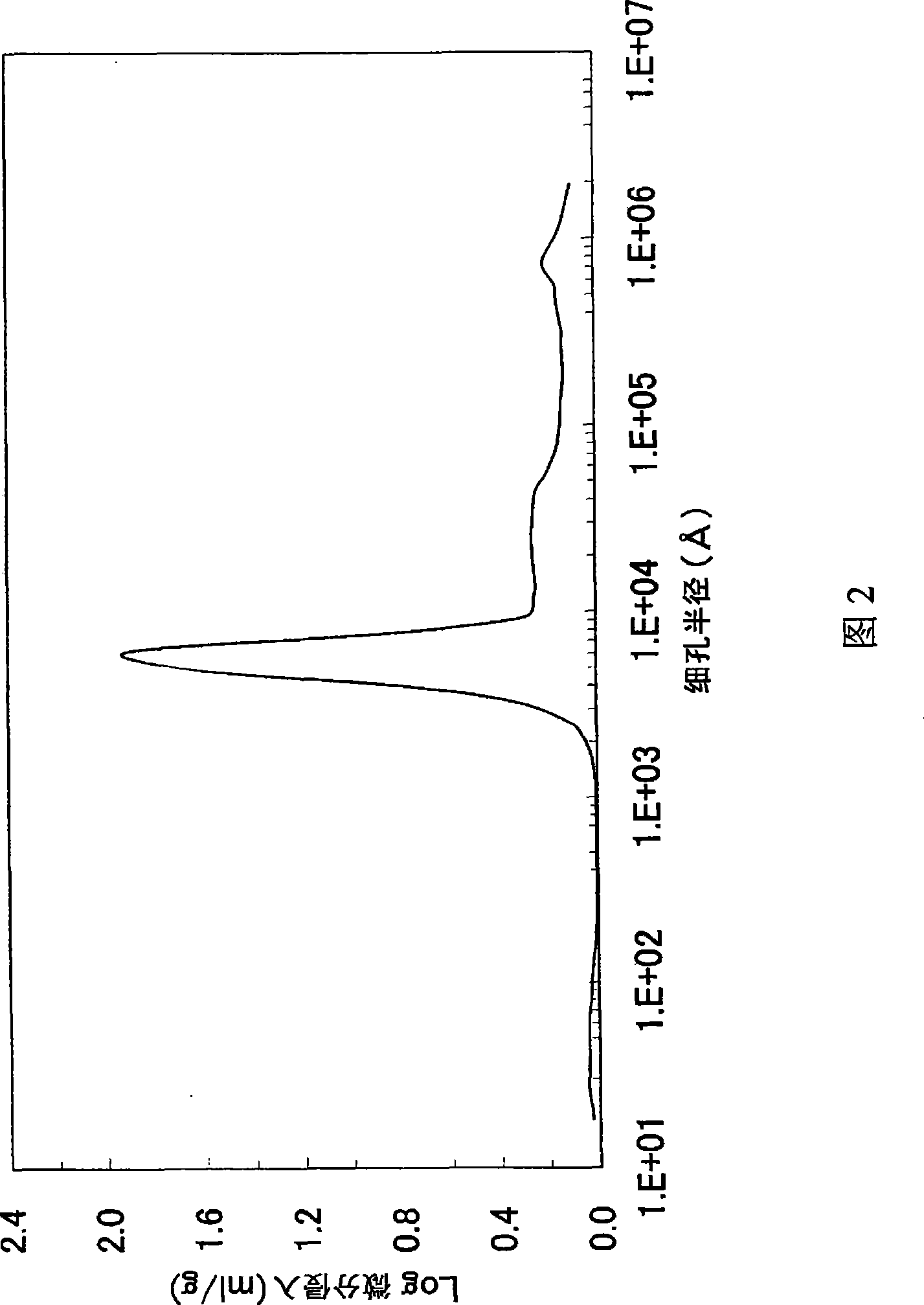

[0823] Put about 15 g of the granular powder obtained by spray-drying the slurry with a spray dryer into an alumina crucible, and calcine it at 1000°C for 12 hours in an air atmosphere (temperature rise and fall rate 5°C / min). , crushed to obtain a volume resistivity of 9.2×10 5 Ω·cm, the carbon content is 0.059% by weight, and the composition is Li 1.067 (Li 0.167 Ni 0.254 mn 0.579 )O 2 The lithium nickel manganese composite oxide (x=0.167, y=0, z=0.067). Its average primary particle size is 0.5 μm, median particle size is 3.6 μm, D 90 It is 4.6μm, the bulk density is 1.0g / cc, and the BET specific surface area is 2.1m 2 / g.

Embodiment 3

[0825] Weigh Li 2 CO 3 , Ni(OH) 2 , Mn 3 o 4 , the molar ratio is Li:Ni:Mn=1.211:0.333:0.556, after mixing, add pure water to prepare slurry. While stirring the slurry, the solid components in the slurry were pulverized to a median particle size of 0.17 μm with a circulating medium agitation type wet pulverizer.

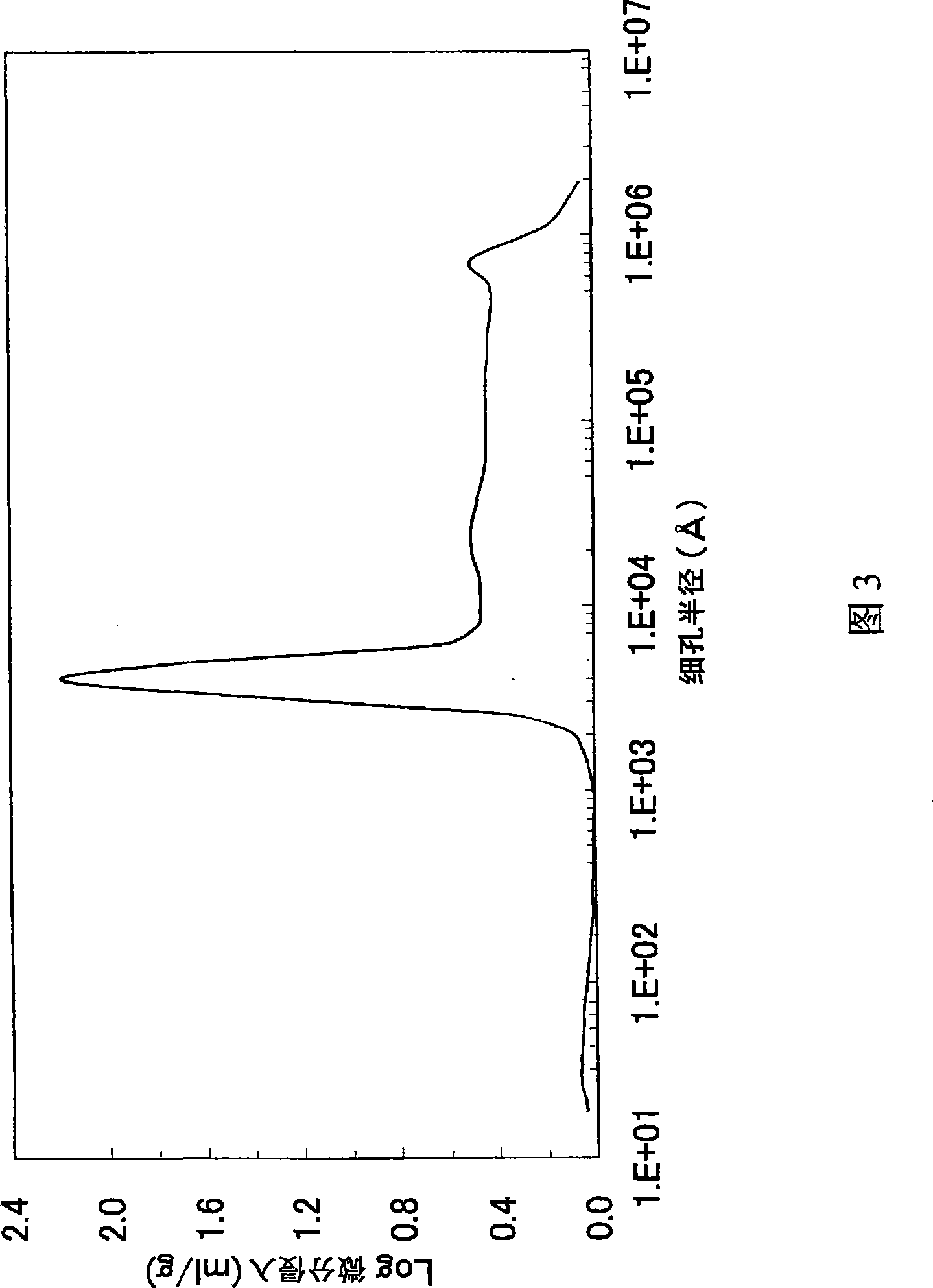

[0826] Put about 15 g of the granular powder obtained by spray-drying the slurry with a spray dryer into an alumina crucible, and calcine it at 900°C for 12 hours in an air atmosphere (temperature rise and fall rate 5°C / min). , crushed to obtain a volume resistivity of 2.0×10 5 Ω·cm, the carbon content is 0.084% by weight, and the composition is Li 1.066 (Li 0.111 Ni 0.334 mn 0.555 )O 2 The lithium nickel manganese composite oxide (x=0.111, y=0, z=0.066). Also, it was confirmed that the crystal structure was composed of a layered R(-3)m structure. Its average primary particle size is 0.2 μm, median particle size is 2.7 μm, D 90 It is 5.1μm, the bulk dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com