Method for processing sewage to agricultural land water using UAFB reactor

A technology for domestic sewage and farmland water, which is applied in the field of farmland water, can solve the problems of high sewage treatment costs and large consumption, and achieve the effects of maintaining stable pollution indicators, avoiding loss, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

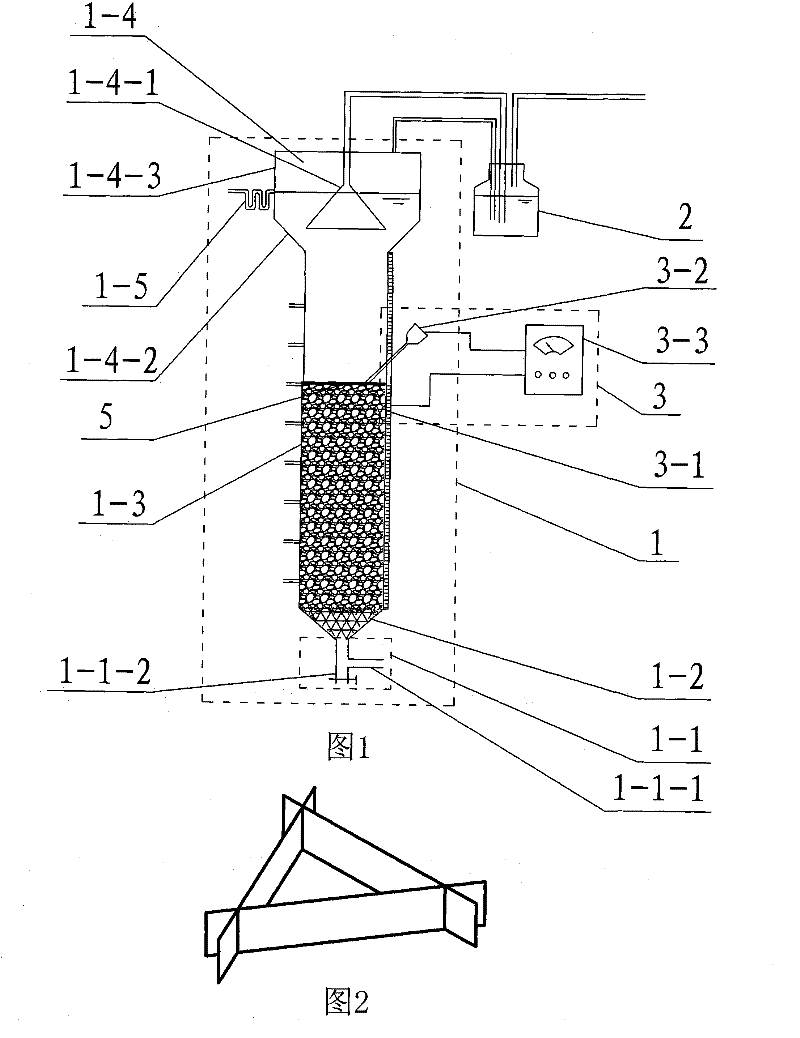

[0021] Specific implementation mode one: as figure 1 As shown, the method of utilizing the UAFB reactor to treat domestic sewage into farmland water in this embodiment is realized by the following steps: Step 1, the domestic sewage to be treated passes through the lower end water inlet 1-1-1 of the main body 1 of the UAFB reactor From bottom to top, it enters the inverted cone body 1-2 equipped with coarse filler, the cylinder body 1-3 equipped with main filler and the sedimentation section 1-4, and the volume of the main filler housed in the cylinder body 1-3 is Two-thirds of the volume of cylinder 1-3; step 2, keep the temperature of the domestic sewage to be treated in the main body 1 at 35-37 °C; step 3, keep the domestic sewage to be treated in the main body 1 for 3-4 hours; step Four, be provided with three-phase separator 1-4-1 at settling section 1-4, by three-phase separator 1-4-1, sludge, sewage and gas in the domestic sewage to be treated are separated; Step 5, sep...

specific Embodiment approach 2

[0022] Specific implementation mode two: as figure 1 As shown, the coarse filler in this embodiment is a plastic suspension filler, and the height of the coarse filler is 10 cm. Others are the same as in the first embodiment.

specific Embodiment approach 3

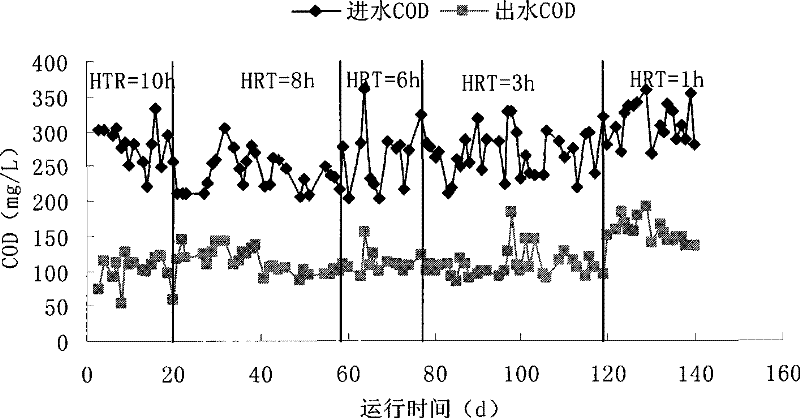

[0023] Specific implementation mode three: as figure 2 As shown, the unit particle of the coarse filler in this embodiment is a hollow triangular body with a height of 1 cm formed by inserting three rectangles with length×width=5cm×1cm. Others are the same as in the first embodiment.

[0024] Specific implementation mode four: as figure 1 As shown, the unit particle of the main filler in this embodiment is ring-shaped, the outer diameter of the ring is 10mm, the specific gravity of the main filler is 0.965-0.968, and the specific surface area of the main filler is 3m 2 / g; the specific gravity of the main filler after supporting the film is 0.98. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com