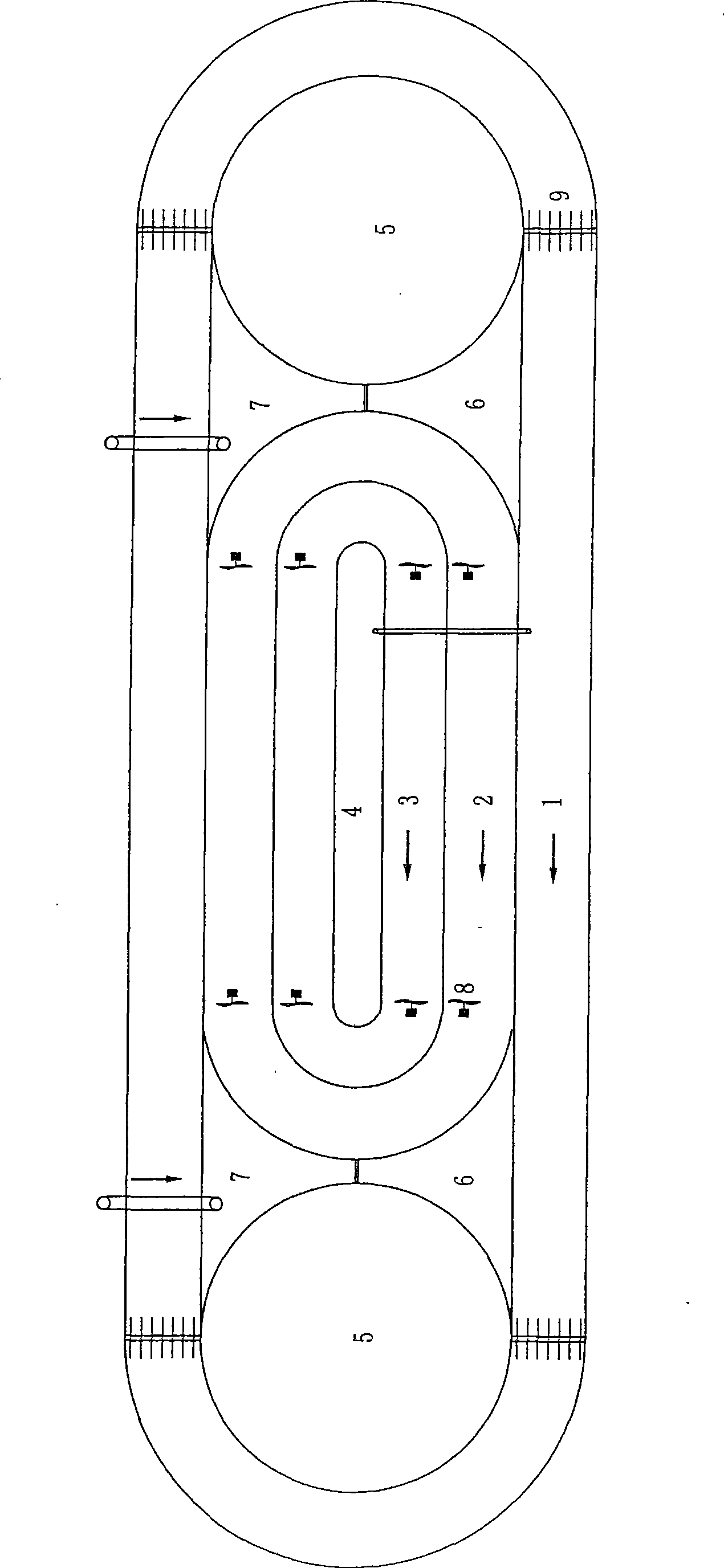

ORBAL oxidation ditch-related type phosphorus and nitrogen removal integrated reverse A<2>O technology

An oxidation ditch and denitrification technology, applied in the field of sewage treatment, can solve problems such as unsatisfactory circulation effect, narrow middle ditch, difficult circulation, etc., and achieve the effect of superior nitrogen and phosphorus removal, ideal circulation effect, beautiful and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] ORBAL-like oxidation ditch integrated phosphorus and nitrogen removal inversion A 2 O process, including outer ditch 1, middle ditch 2, inner ditch 3 and central island 4, secondary settling tank 5 is built at one end or two ends of the inner wall of outer ditch 1, tangent to or separated from the outer wall of middle ditch 2, outer ditch 1 Inner wall, middle ditch 2 outer wall, secondary settling tank 5 The area between the outer walls is divided into nitrifying liquid return area 6 and sludge return area 7 by partition walls, outer ditch 1 is designed as an aerobic tank, and middle ditch 2 is designed as anoxic pool, the inner ditch 3 is designed as an anaerobic pool, the central island 4 is set as an aerobic area, and the pipeline is connected to the outer ditch 1 aerobic pool, and the anoxic pool in the middle ditch 2 and the inner ditch 3 anaerobic pool are provided with underwater propellers 8. Microporous aerators or surface aerators 9 are added to the oxygen tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com