Coal-fired power plant ultralow discharger with independent support structure

A technology for coal-fired power plants and emission devices, applied in the directions of external electrostatic separators, steam/steam condensers, lighting and heating equipment, etc., which can solve the difficult layout of wet electrostatic precipitators, increased floor space, and large flue resistance, etc. problems, to achieve the effect of reducing the initial investment of the project, reducing the power consumption of the operation, and reducing the resistance of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings:

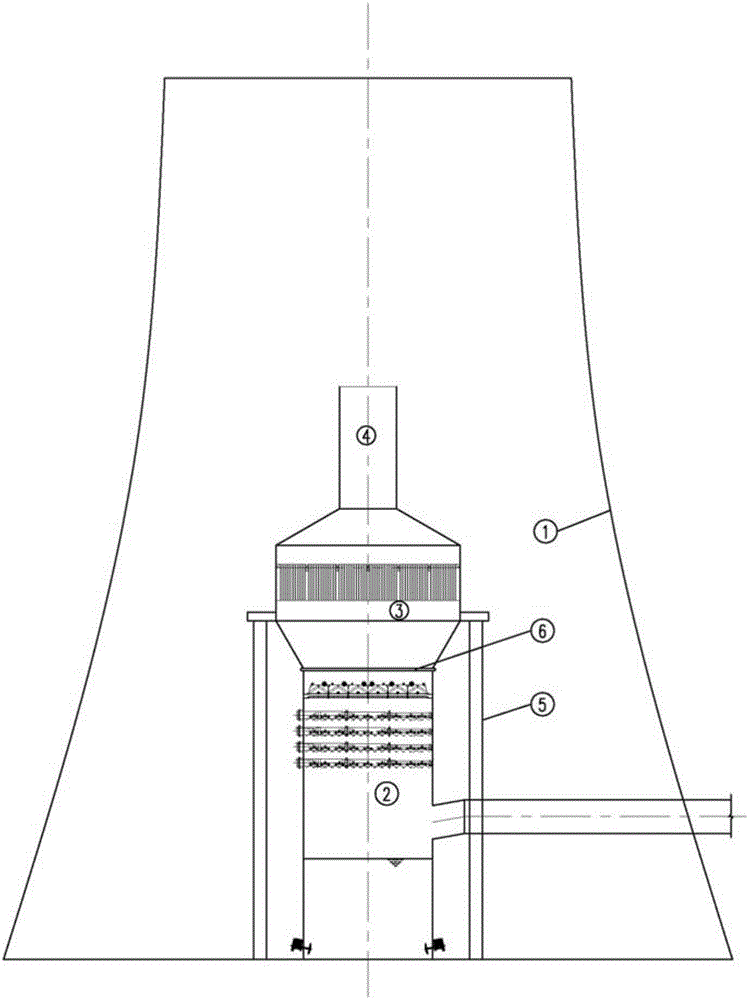

[0019] reference figure 1 , The ultra-low emission device for coal-fired power plant with independent support structure according to the present invention includes an indirect cooling tower 1, and a support frame 5 arranged in the indirect cooling tower 1, a desulfurization absorption tower 2, a dust collector 3, and a smoke exhaust device 4 , Wherein the desulfurization absorption tower 2, the dust collector 3 and the smoke exhaust device 4 are distributed from bottom to top, and the flue gas outlet of the desulfurization absorption tower 2 is connected with the flue gas inlet of the dust collector 3, and the flue gas outlet of the dust collector 3 Connected with the inlet of the smoke exhaust device 4, the desulfurization absorption tower 2 is erected at the bottom of the intercooling tower 1; the desulfurization absorption tower 2 and the dust collector 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com