Vitamin D3 preparation method and device

A technology of vitamins and equipment, applied in the field of vitamins, can solve the problems of large ultraviolet absorption, many side reactions of polymerization, and no consideration of use, etc., and achieve the effect of high content, less side reactions of polymerization, and avoid deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

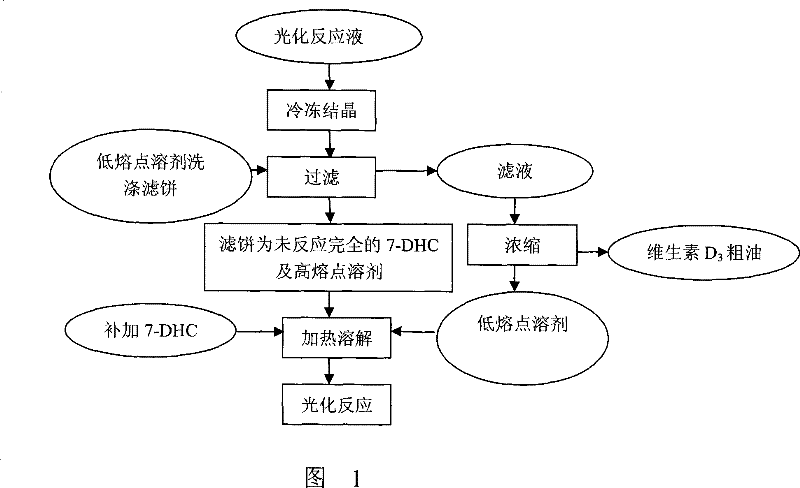

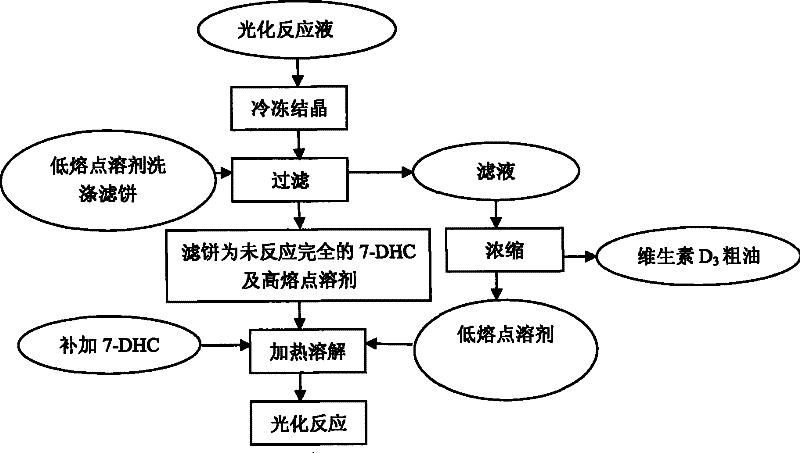

Method used

Image

Examples

Embodiment 1

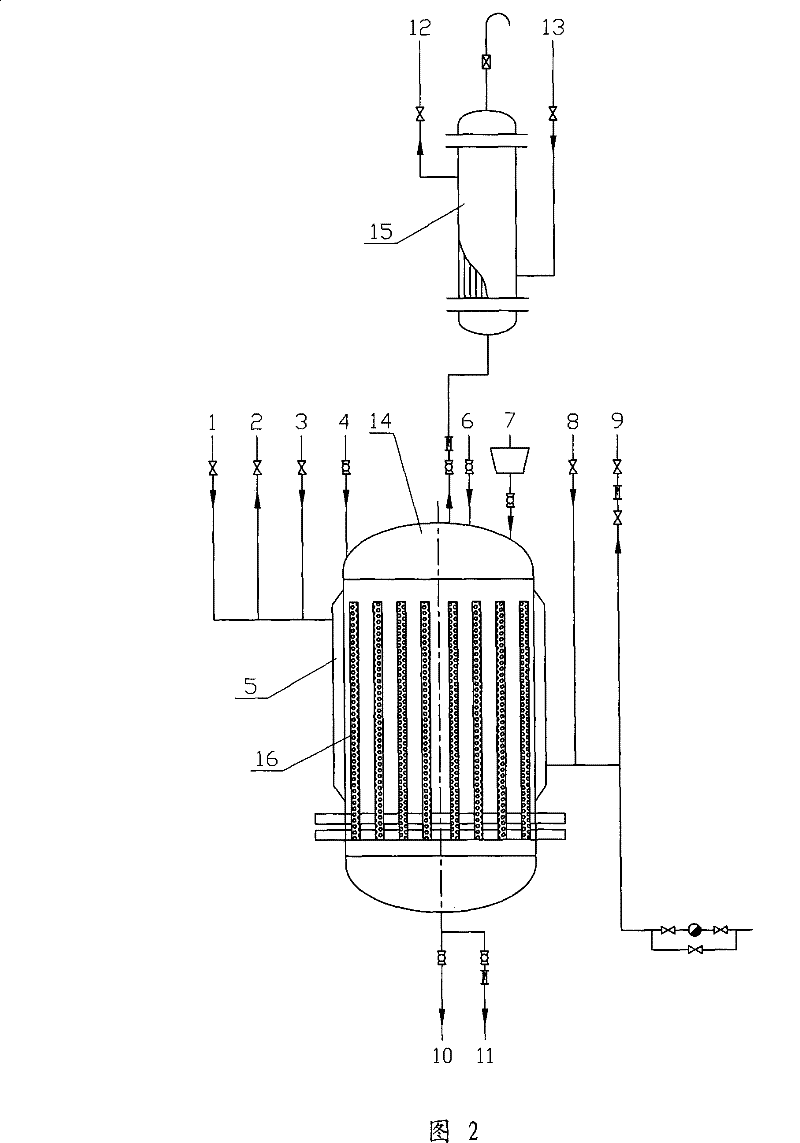

[0017] As shown in the figure, the equipment used in the post-treatment process is composed of a crystallization-filter 14 and a tail gas condenser 15 connected in series with it. The crystallization-filter 14 is composed of a container body, a plurality of tubes 16 placed in the container body, Jacket 5 on the container body and steam inlet valve 1, nitrogen inlet valve 3, photochemical reaction liquid inlet valve 4, washing solvent inlet valve 6, 7-dehydrocholesterol feeding inlet valve installed on the container body 7. The outlet valve 10 and the filtrate outlet valve 11 are composed. The jacket 5 is equipped with a chilled brine backwater 9, an inlet valve 8, and the tail gas condenser 15 is also equipped with a chilled brine backwater 12 and an inlet valve 13. The aforementioned filtrate discharge valve 11 is connected to a filtrate concentration kettle, and the discharge valve 10 is directly connected to the photochemical reactor. The outer surface of the tube 16 is wrap...

Embodiment 2

[0023] When the reaction liquid obtained from the photochemical reaction is subjected to post-treatment, the crystallization-filter drain valve is opened, the frozen brine return water 12 of the tail gas condenser, and the water inlet valve 13 are opened. Open the feed port valve 4 and put 1000Kg of the photochemical reaction liquid (which contains 700Kg of cyclohexane, 200Kg of ethanol, 56Kg of 7-dehydrocholesterol, 56Kg of 7-dehydrocholesterol, and vitamin D) into the crystallization-filter. 3 Crude oil 14Kg). After the feed is completed, open the crystallization-filter jacket frozen brine return valve 2 and the water inlet valve 8, and pass the -20°C frozen brine into the crystallization-filter jacket for frozen crystallization. When the temperature in the crystallization-filter reaches below -5°C, start timing, and the crystallization can end after about 5 hours.

[0024] After the crystallization is completed, turn off the chilled brine inlet 13 and the return valve 12 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com