No-shaft underground gasification process

An underground gasification and process technology, which is applied in coal gasification, underground mining, construction, etc., can solve the problems that the reliability of ignition cannot be guaranteed, and it is difficult to ensure the smooth dragging of the igniter, so as to achieve protection stability, ensure stability, shorten The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

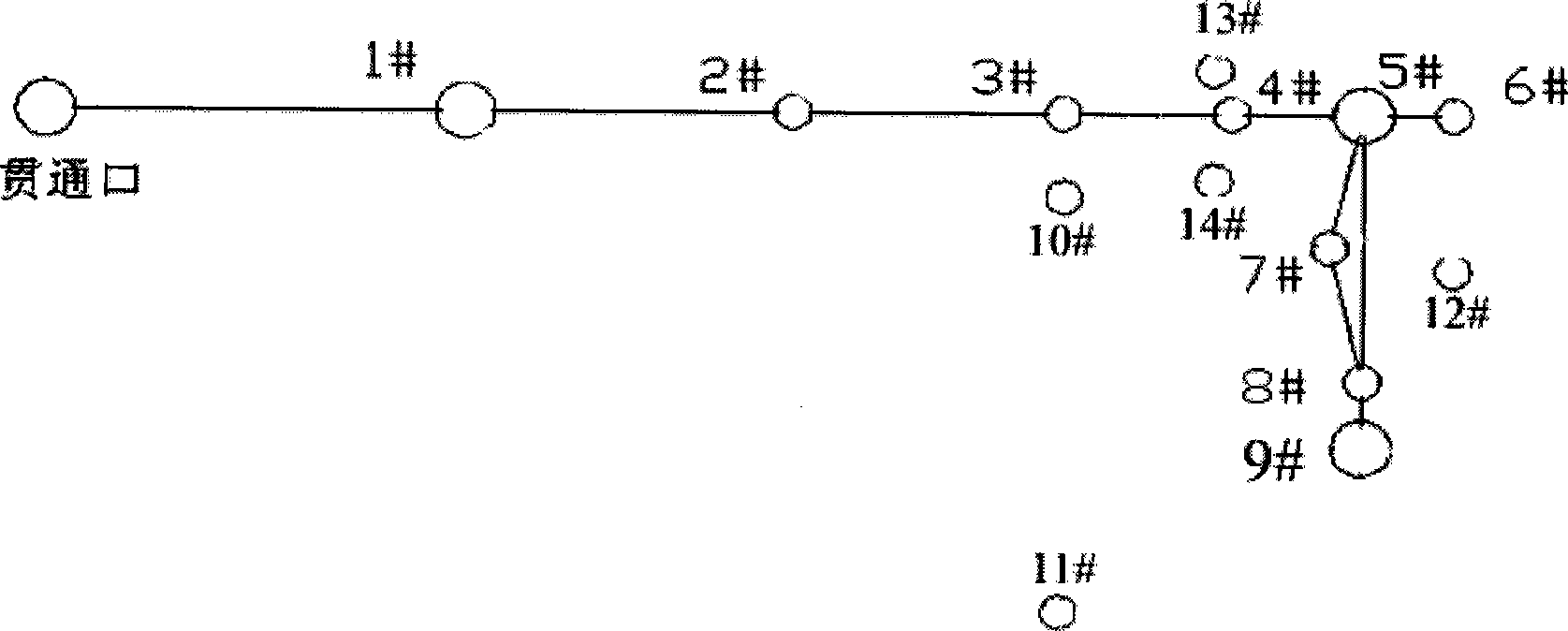

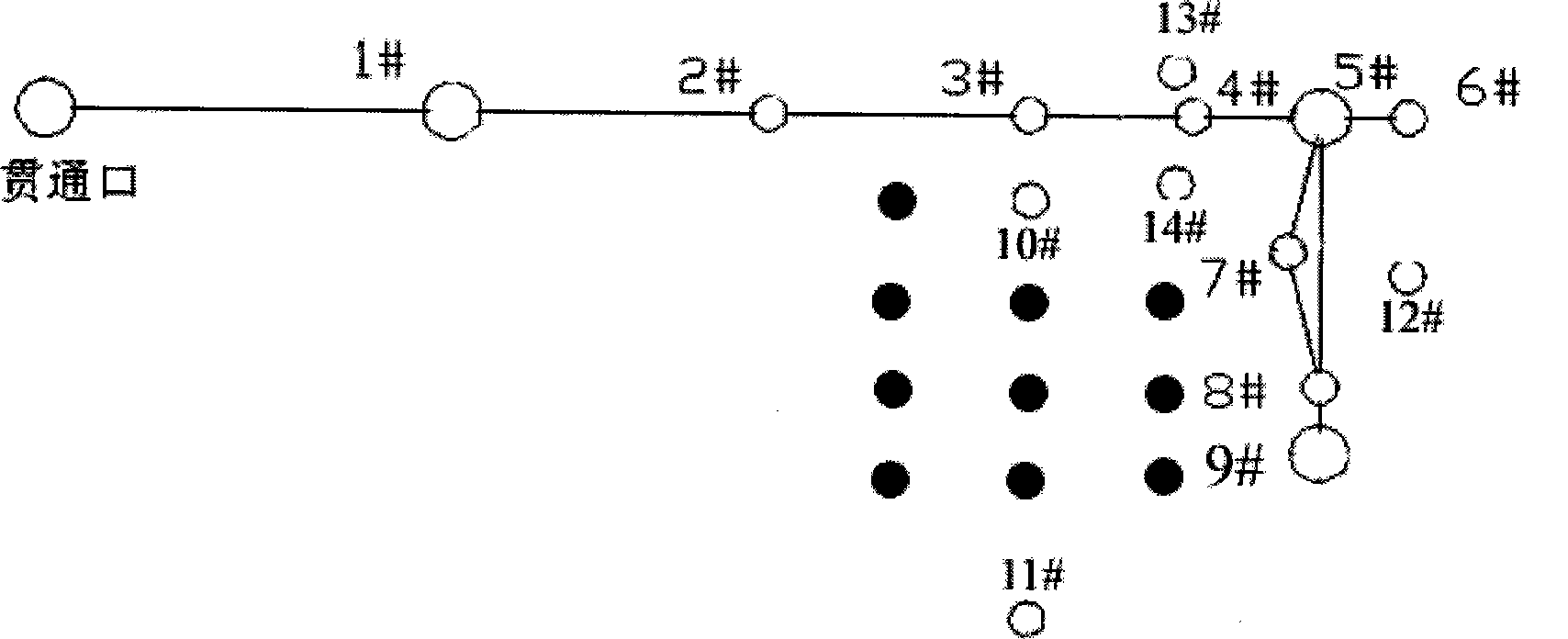

[0027] figure 1 The floor plan of the "L" type gasification is illustrated, in which, No. 1, 2, 3, 4, 5, and 6 holes are penetrated by directional drilling, and No. 6 holes are drainage holes; No. 5, 7, 8, and 9 holes The borehole is pierced by fire. The distance between No. 1 and the through-hole is 190 meters, the distance between No. 1 and No. 2 is 55 meters, the distance between No. 2 and No. 3 is 45 meters, the distance between No. 3 and No. 4 is 25 meters, the distance between No. 4 and No. 5 is 22 meters, and the distance between No. 5 and No. 6 The distance between No. 5 and No. 7 is 15 meters, the distance between No. 5 and No. 7 is 24.5 meters, the distance between No. 7 and No. 8 is 24.8 meters, and the distance between No. 8 and No. 9 is 12 meters. Among them, the main inlet and outlet holes 1, 5, and 9 have a diameter of 325mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com