Multi-segment of furnace configuration monitoring system based on temperature field analysis

A technology of configuration monitoring and multi-furnace sections, which is applied in the general control system, control/regulation system, furnace components, etc., to achieve good economic benefits, improve product sintering quality, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical scheme is further explained and illustrated below with non-limiting examples.

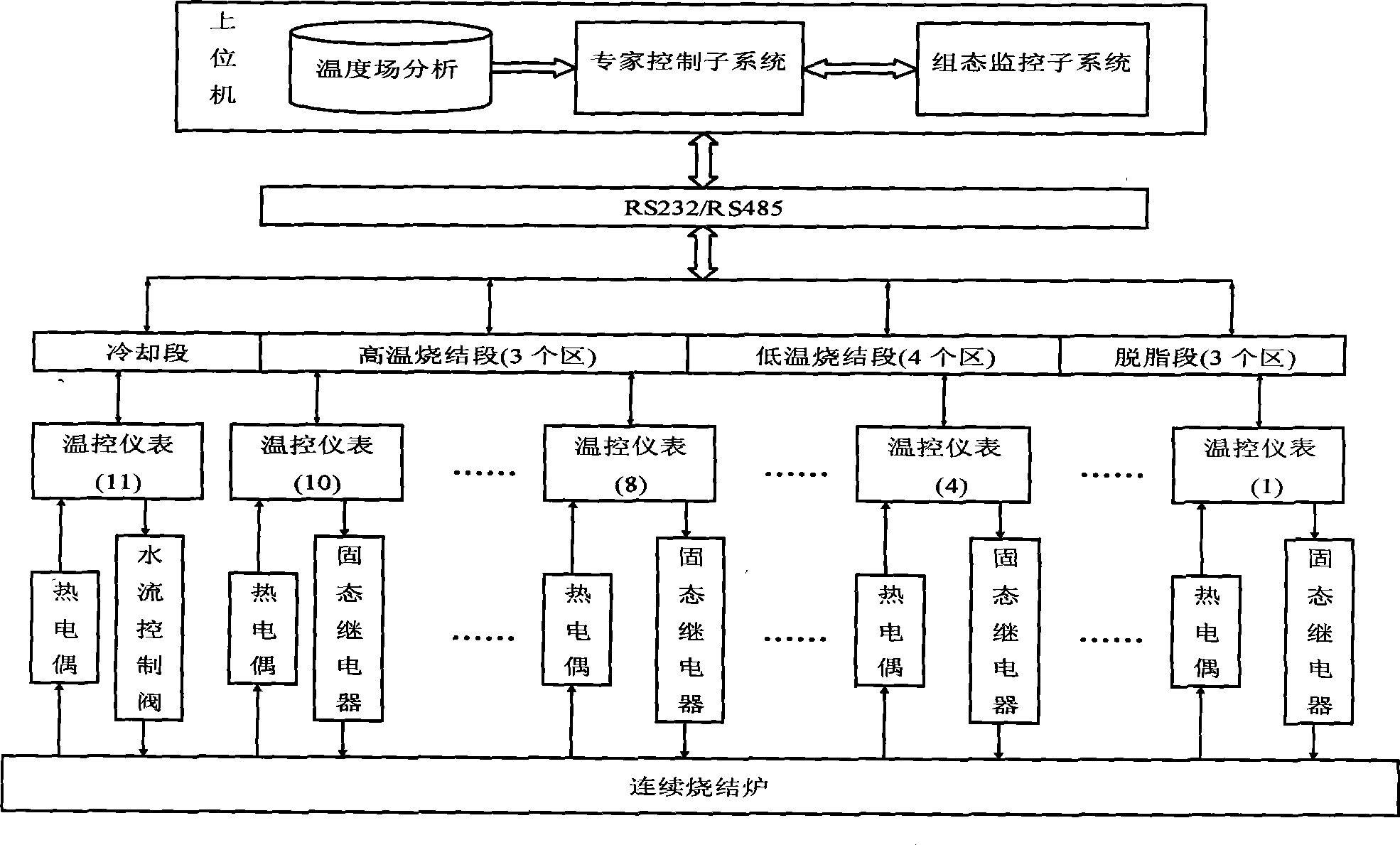

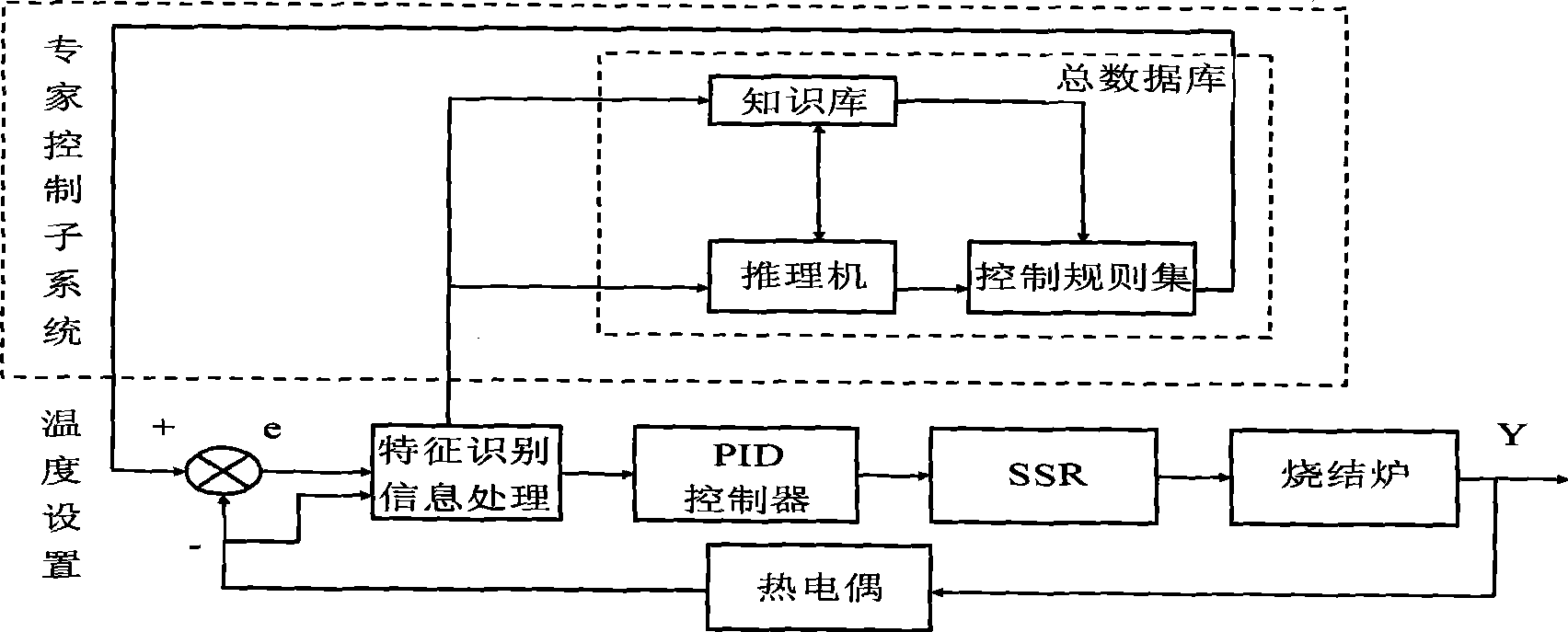

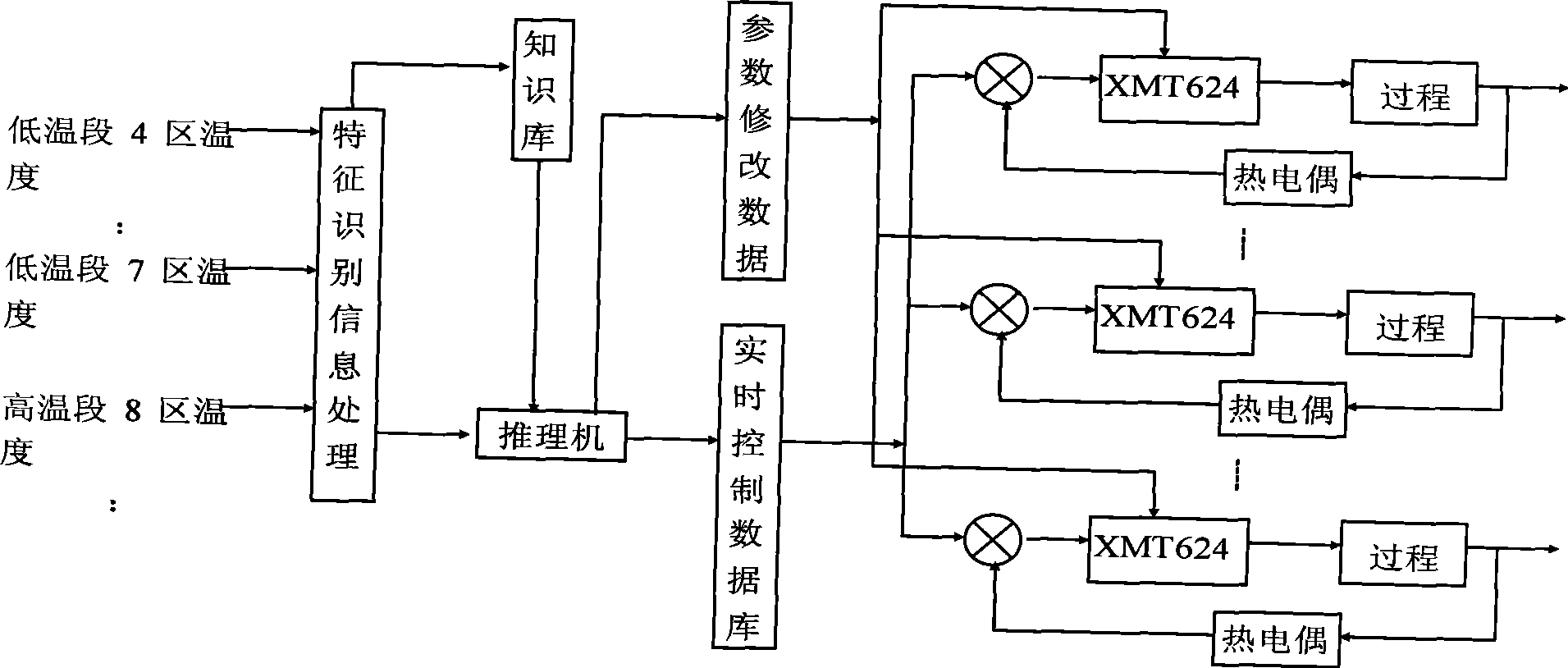

[0034] A multi-furnace section configuration monitoring system based on temperature field analysis, such as figure 1 As shown, including the continuous sintering furnace, the continuous sintering furnace includes a degreasing section, a low-temperature sintering section, a high-temperature sintering section and a cold treatment section. The continuous sintering furnace can be divided as follows: the debinding section is divided into 3 areas, and the low-temperature sintering section is divided into 4 areas. The high-temperature sintering section is divided into 3 zones, and the cooling section is regarded as one zone. There are 11 zones in total. From the degreasing section to the cooling section, they are defined as zone 1, zone 2, ..., zone 11 in sequence, and each zone is correspondingly equipped with a The sensor and a solid-state relay are connected with a temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com