Laser reflection expanding cone and method for manufacturing same

A laser reflection and manufacturing method technology, applied in photometry, optical radiation measurement, measuring devices, etc., can solve problems such as poor reliability, difficult processing of laser reflection beam expansion, poor scalability, etc., to solve processing problems and improve resistance Laser radiation damage ability, effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

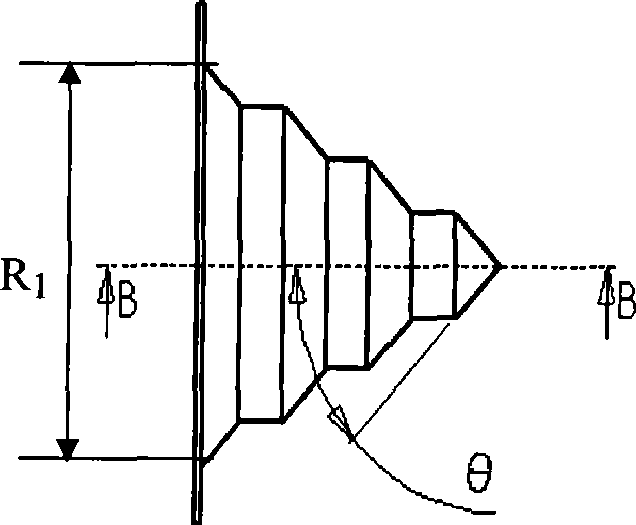

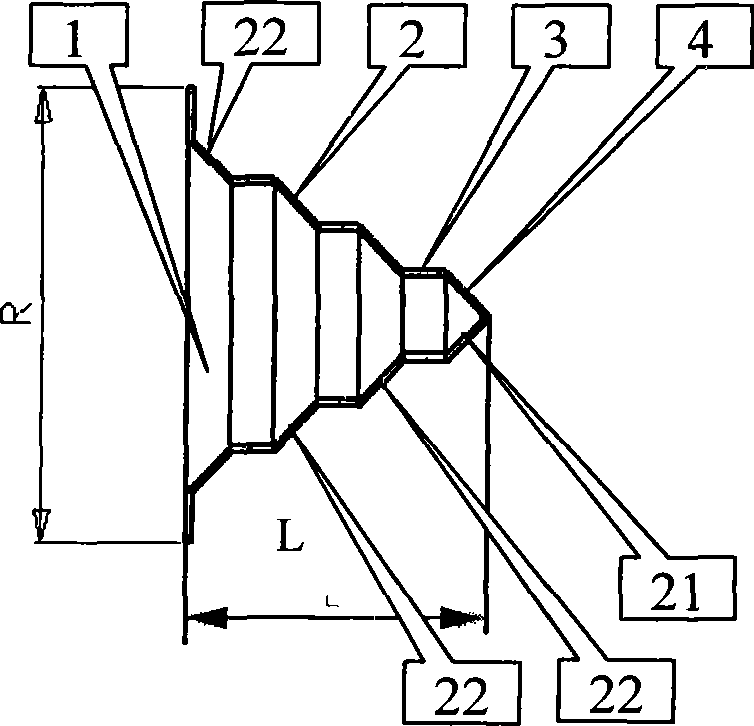

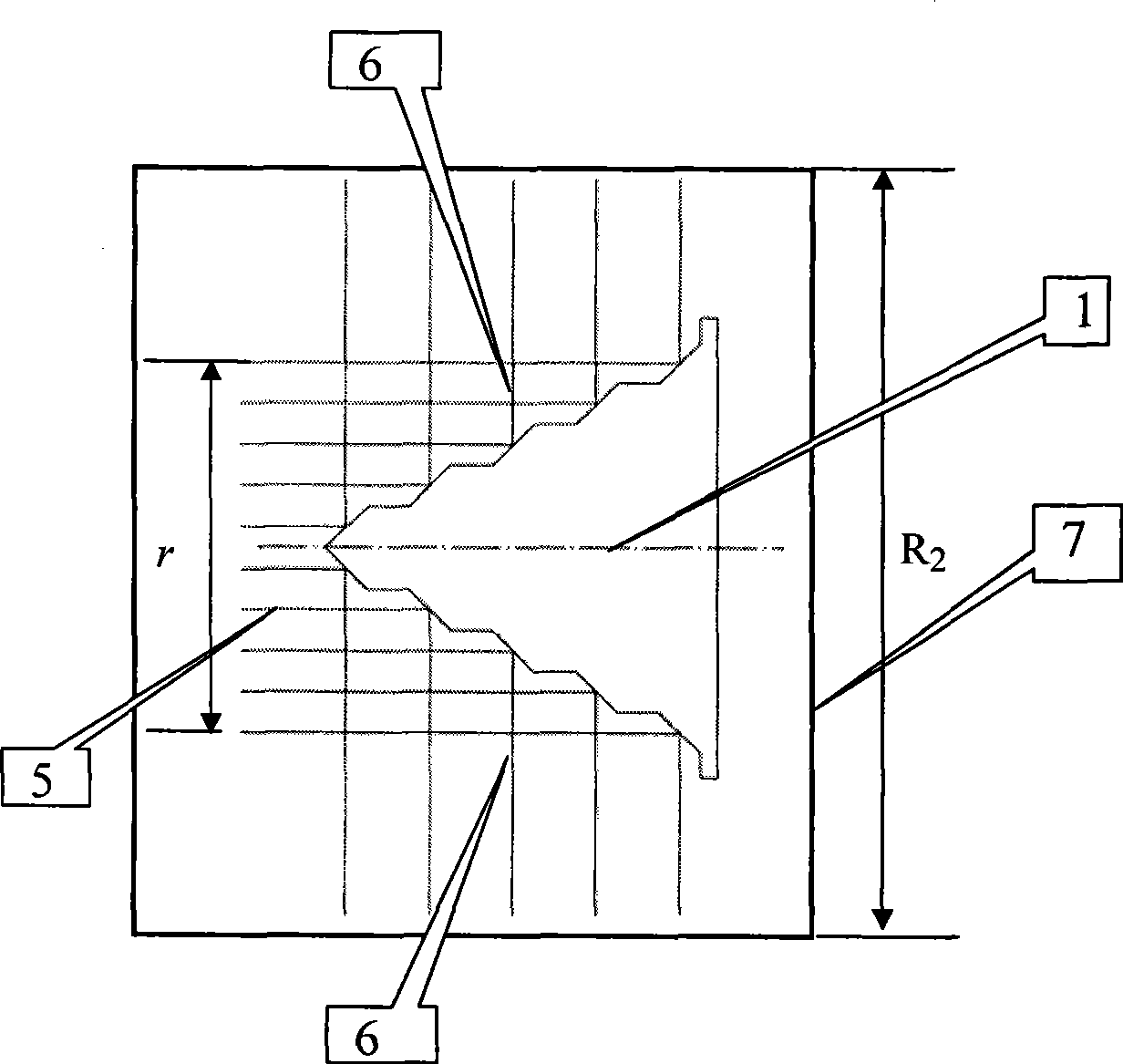

[0029] The structure of the stepped laser reflection beam expander cone is as follows: figure 1 and figure 2 As shown, the main body of the stepped laser reflective beam expander cone of the present invention is a bottom outer ring with a diameter of R and an inner ring with a diameter of R 1 , a hollow cone structure with height L and cone angle θ. The cone surface is composed of a stepped structure with a cone reflection section separated by a cone connection section. figure 1 and figure 2 There are 4 conical reflective sections and 3-end conical connecting sections in total, of which 4 conical reflective sections include 1 conical conical reflective section and 3 conical conical reflective sections; usually the cone angle θ is taken as 45 degrees , The length of the cone, the size of the cone angle, etc. can be flexibly designed according to actual needs. The conical surface reflection section controls and expands the direction of the laser incident beam. By changing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com