Flow speed measurement sensor

A flow velocity measurement and sensor technology, applied in fluid velocity measurement, measuring device, velocity/acceleration/impact measurement, etc., can solve the problem of not being able to measure water flow velocity in time, achieve less influence, better measure water flow, and improve linearity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

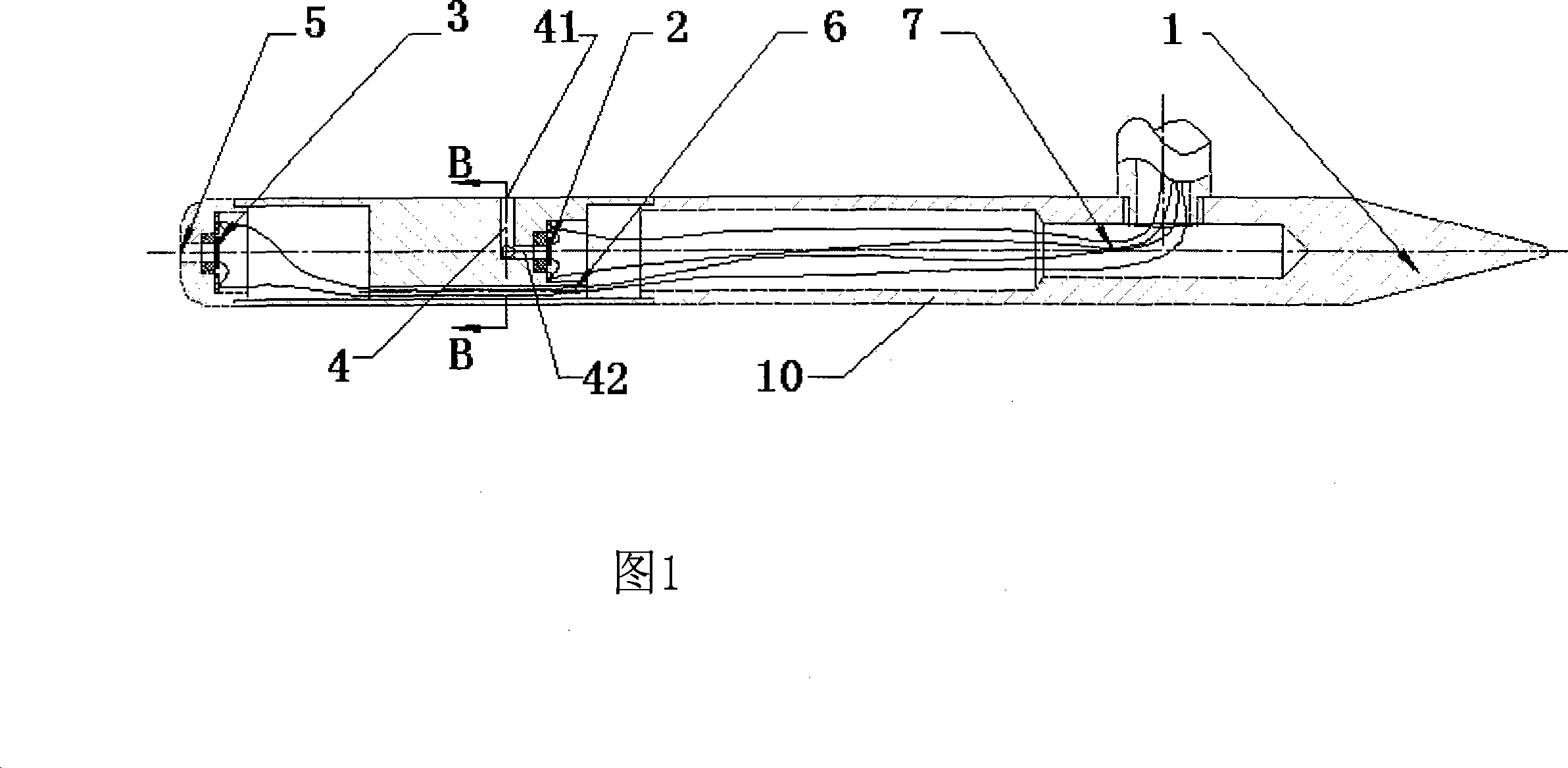

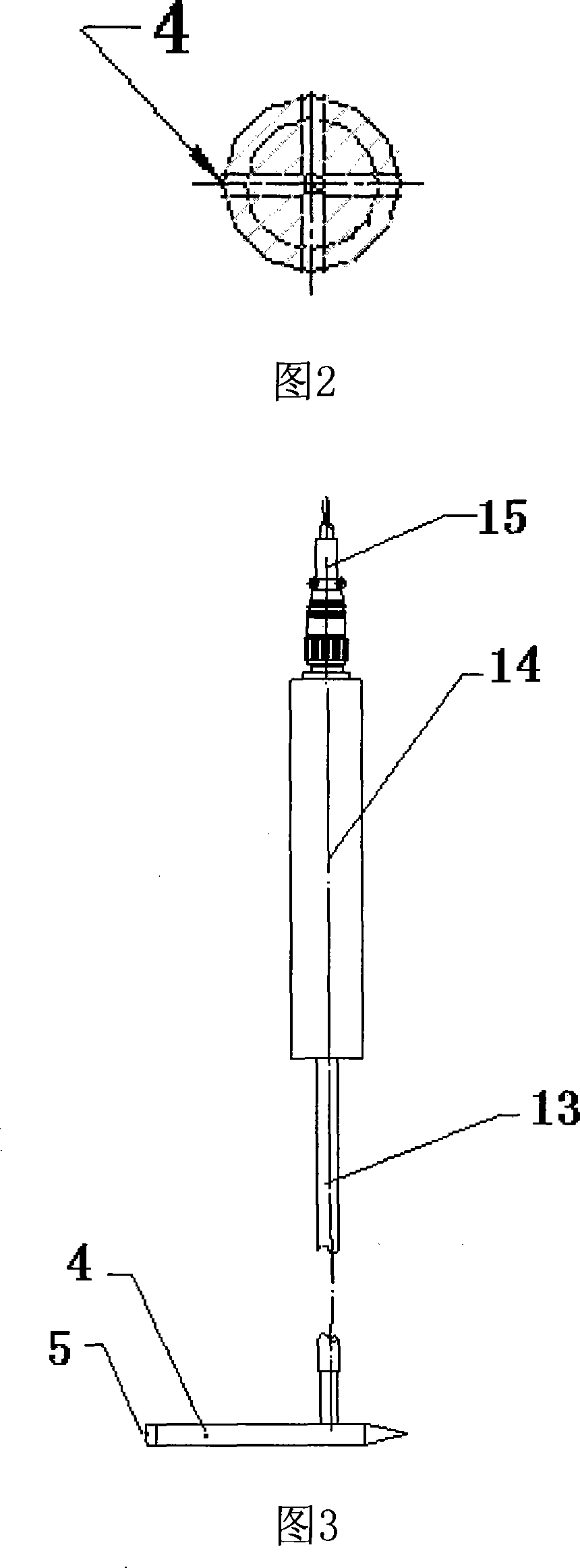

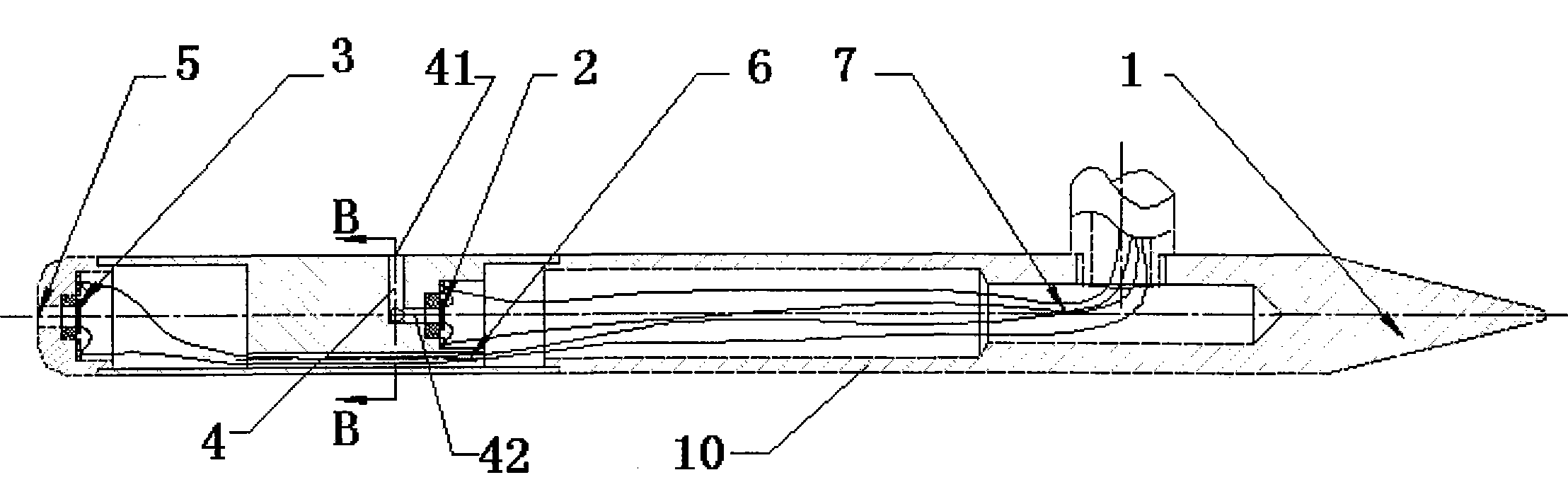

[0025] combine figure 1 , to be further described below: a flow velocity measurement sensor is composed of a Pitot tube 10, a total pressure sensor and a static pressure sensor that are respectively arranged at the front end of the Pitot tube (also known as the total pressure measuring point facing the water) and the side. The pressure sensor and the static pressure sensor are respectively composed of silicon piezoresistive sensitive components. The silicon piezoresistive sensitive component 3 in the total pressure sensor is arranged in the lumen at the front end of the Pitot tube, and is aligned with the total pressure inlet hole 5 at the front end of the lumen. Flat installation. And the silicon piezoresistive sensitive component 2 in this static pressure sensor is arranged on this Pitot tube middle lumen, and installs flush with the output nozzle 42 of the static pressure induction tube 4 in this Pitot tube, this static pressure induction tube 4. The other end is set at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com