Method for autoclave-free adhesive bonding of components for aircraft

An autoclave-free, aircraft technology, used in aircraft parts, air transportation, wings, etc., can solve the problems of time-consuming and expensive, and achieve the effects of reduced post-processing work, low energy consumption, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

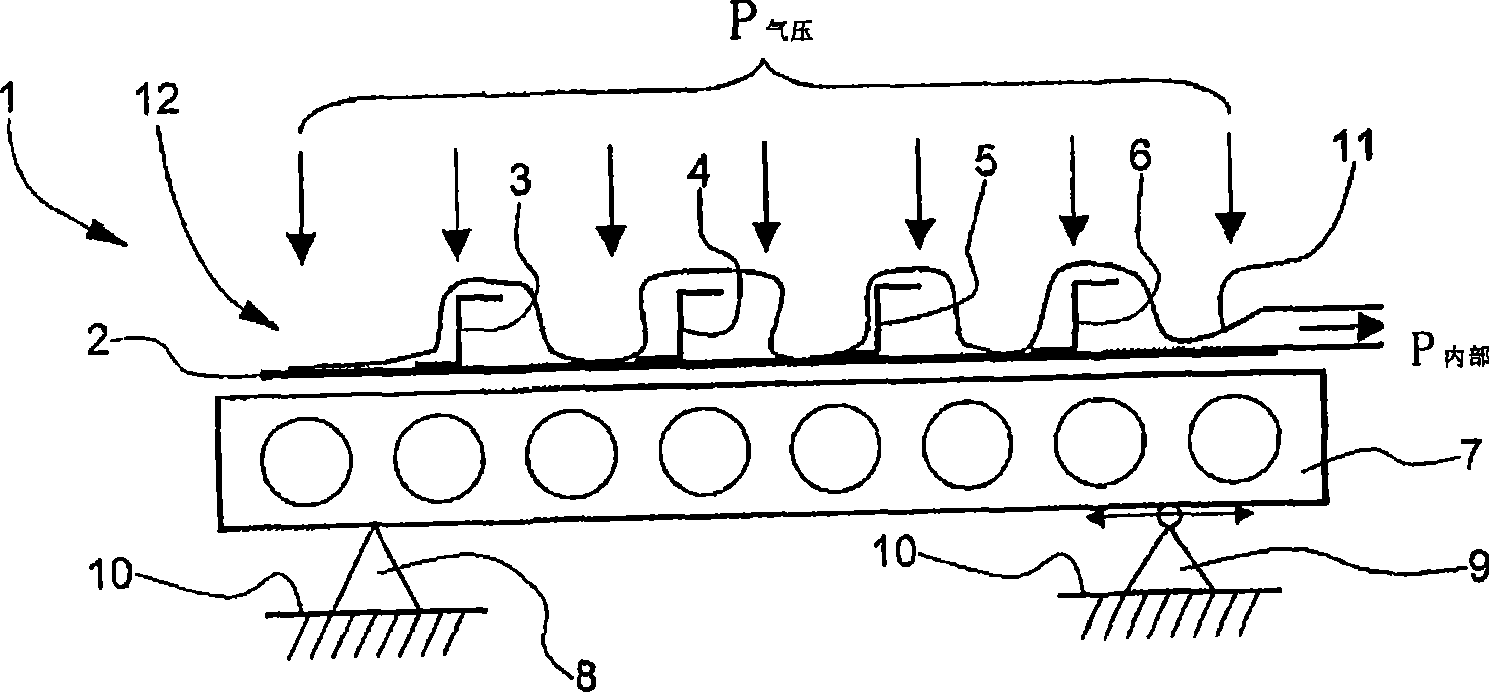

[0043] figure 1 A cross-sectional view is shown of a structure that will have a plurality of components bonded to each other to produce a large-scale structural component 1 according to the method of the invention.

[0044] For example, the large-scale structural component 1 can be a landing flap, a cover skin of an airfoil, a steering unit, a lifting unit, a fuselage skin part with a plurality of windows eg cut away or similar. now refer to figure 1 The steps of the method of the invention are described in more detail below.

[0045] In order to carry out the method, the components 2, 3, 4, 5 and 6 are placed, positioned and mutually aligned with respect to each other on the support structure 7. exist figure 1Part 2 in the exemplary embodiment shown in is a skin panel composed of an aluminum alloy that will be glued to the positioned parts 3 to 6 to reinforce the parts 3 to 6 . The components 3 to 6 can also be referred to as stringers or reinforcing profiles with a subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com