Forming method of automobile generator claw pole

An automotive generator and claw pole technology, applied in the manufacture of motor generators, engine components, wheels, etc., can solve the problems of high man-hours and energy consumption, poor surface quality of parts, long process steps, etc., to improve capacity and forming quality. Good, good size performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

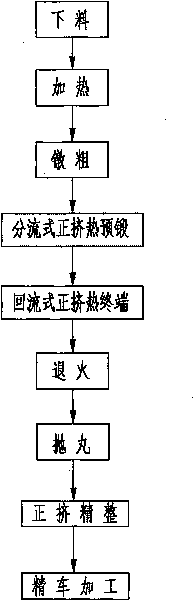

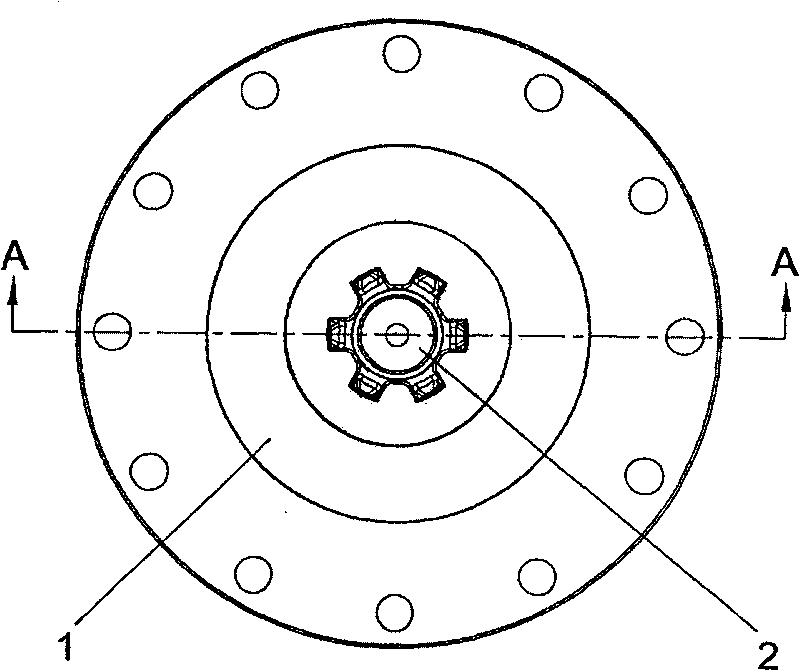

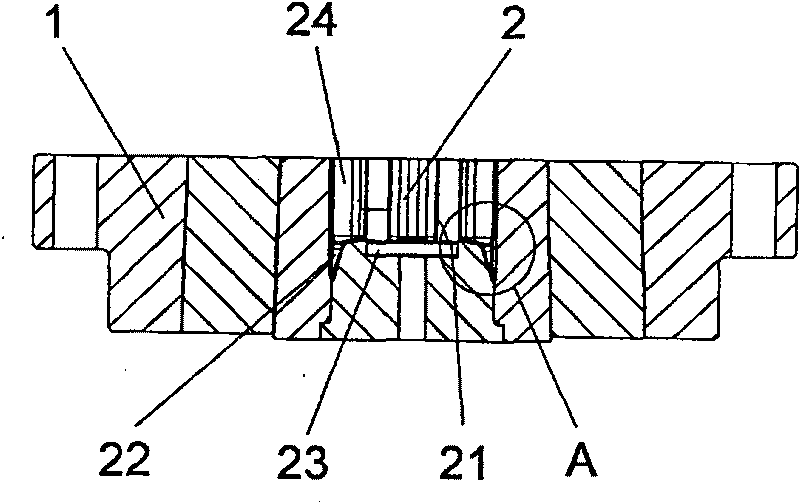

[0042] see Figure 1-Figure 20 , The invention includes blanking, heating, upsetting, shunt type forward extrusion hot pre-forging, reflow type forward extrusion hot final forging, annealing, shot blasting, forward extrusion finishing and finish turning. Blanking, heating, upsetting, annealing, shot blasting, forward extrusion finishing and finish turning in the present invention are all prior art. In the present invention, the split-flow forward extrusion hot pre-forging and the reflow type forward extrusion hot final forging are respectively realized by the hot pre-forging die and the hot final forging die, and both the hot pre-forging die and the hot final forging die are closed precision forging dies , and the hot pre-forging die matches the hot final forging die.

[0043] The hot pre-forging die includes a hot pre-forging die and a hot pre-forging punch, and the hot pre-forging die matches the hot pre-forging punch. The hot pre-forging die comprises a hot pre-forging di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com