Insulating organic waste dry-type anaerobic fermentation system

A dry anaerobic fermentation and organic waste technology, applied in the field of fermentation system, can solve the problems of poor fluidity, poor heat transfer effect, high solid content, etc., and achieve the effects of convenient control, guaranteed effect, and accurate temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

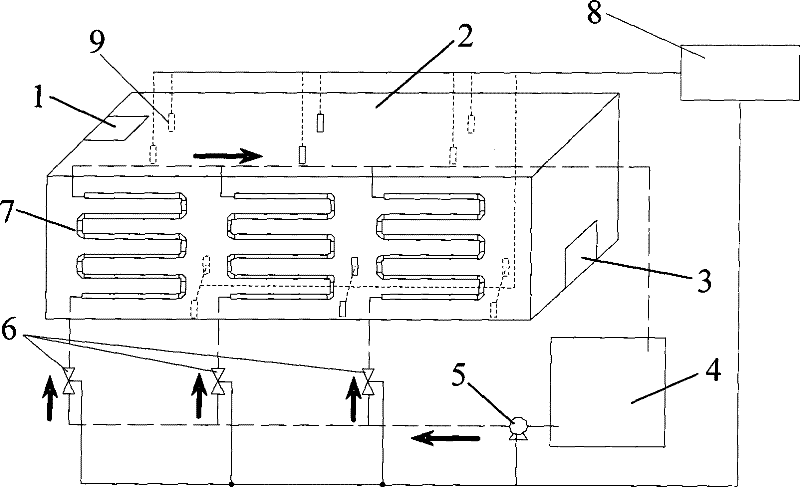

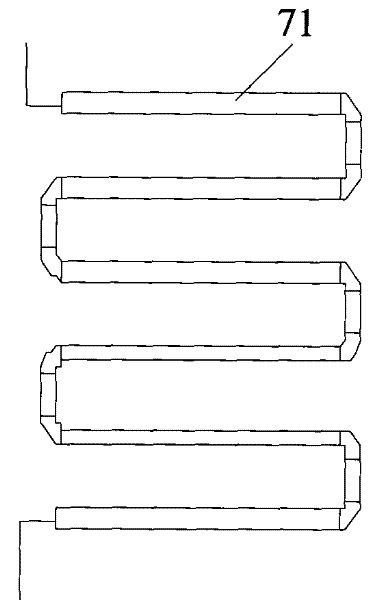

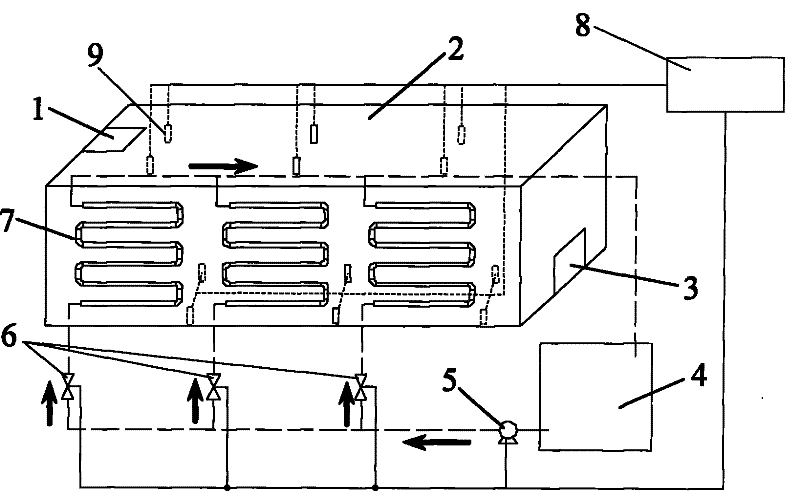

[0031] This embodiment provides a kind of thermal insulation type organic waste dry type anaerobic fermentation system, such as figure 1 As shown, compared with the existing fermentation system, this system can ensure that the temperature in the fermentation tank does not exceed the specified temperature (such as: ± 1 ° C), and the system specifically includes: fermentation tank 2, heat exchange device 7, and heat supply device 4 , a control valve 6, a circulation pump 5, a temperature measuring device 9 and a control device 8; and a feed storage tank, an inoculation mixing tank, a transfer pump, and a biogas slurry that are matched with the fermenter 2 to realize dry anaerobic fermentation treatment of organic waste Equipment such as discharge pipe, reflux pump, spraying device, lye storage tank and air outlet, because the embodiment of the present invention is the specific description of how to realize heat preservation to fermentation system, so each equipment that realizes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com