Motorcycle engine

A technology of engine and cylinder head cover, which is applied in the direction of engine components, engine lubrication, machine/engine, etc. It can solve the problems of no obvious improvement of power, torque and other performance, insufficient lubrication and heat dissipation system, no reduction of vibration and fuel consumption, etc. problem, to achieve the effect of increasing heat dissipation, reducing reciprocating inertial force, and increasing effective output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

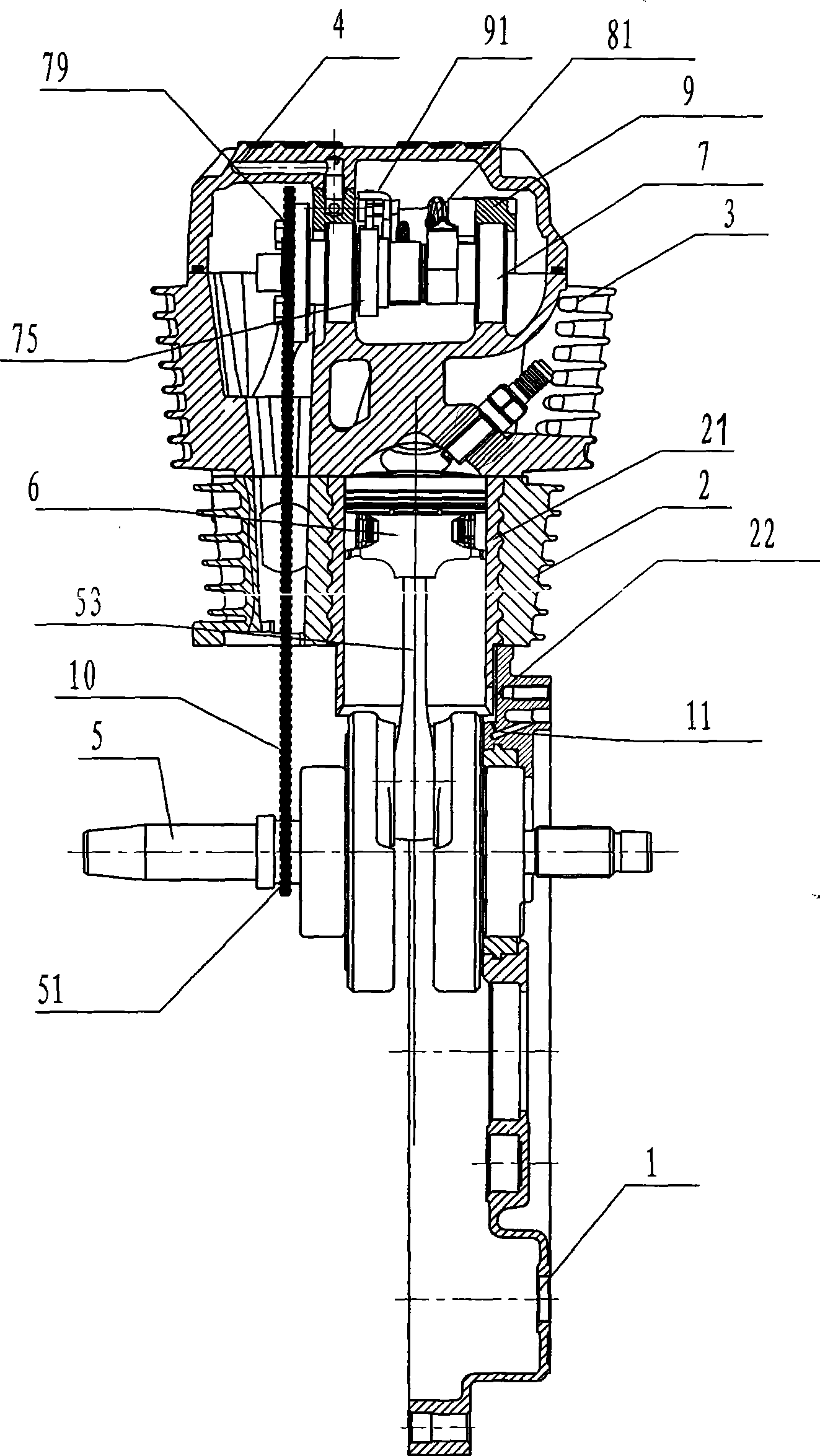

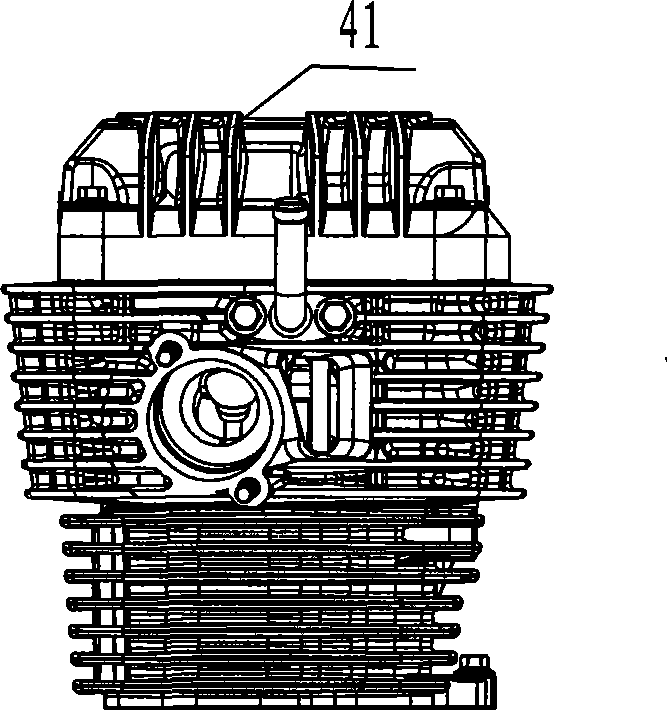

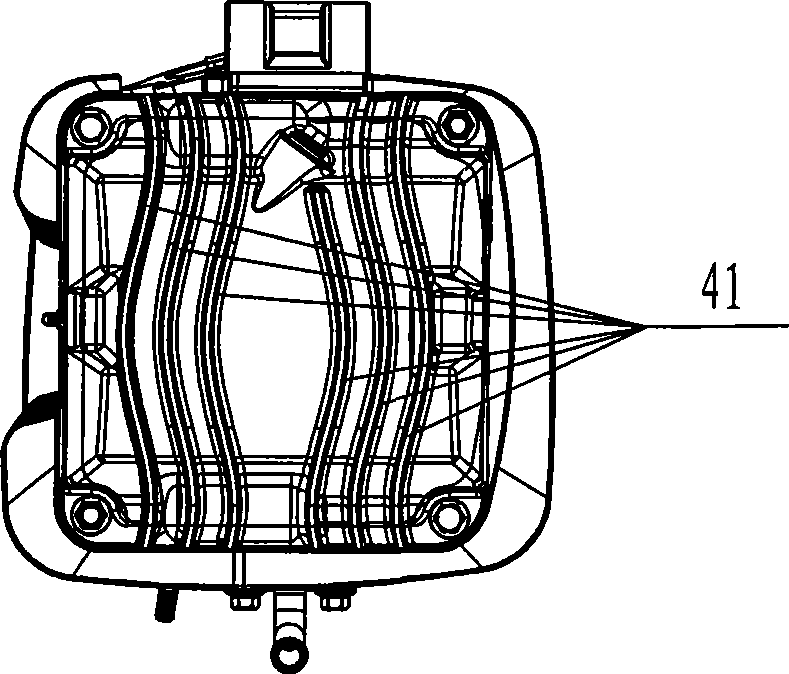

[0036] A motorcycle engine such as Figure 1-16 shown, including cylinder head cover 4, cylinder head 3, cylinder 2, right box 1, camshaft cover 9, intake valve rocker arm 82, exhaust valve rocker arm 81, intake valve rocker arm shaft, exhaust valve rocker arm Shaft 754, stop plate 91, intake cam 76, exhaust cam 77, one-way device 75, driven sprocket 79, chain 10, driving sprocket 51, piston 6, connecting rod 53, crankshaft 5; The top-down assembly structure includes cylinder head cover 4, cylinder head 3, cylinder 2, and right box 1; the engine is equipped with an overhead cam chain type gas distribution structure and a crankshaft connecting rod piston mechanism; the overhead cam chain type gas distribution structure includes Driven sprocket 79, camshaft 71, chain 10, driving sprocket 51, driven sprocket 79 is contained on the camshaft 71, and chain 10 meshes with driven sprocket 79 and driving sprocket 51 respectively; Crankshaft connecting rod piston Mechanism comprises cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com