Round point width flow passage fully-soldering heat exchange plate

A wide flow channel, heat exchange plate technology, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of difficult cleaning, large resistance, easy accumulation of dust, etc., to increase the effective heat exchange area, The effect of improving heat exchange efficiency and strengthening support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

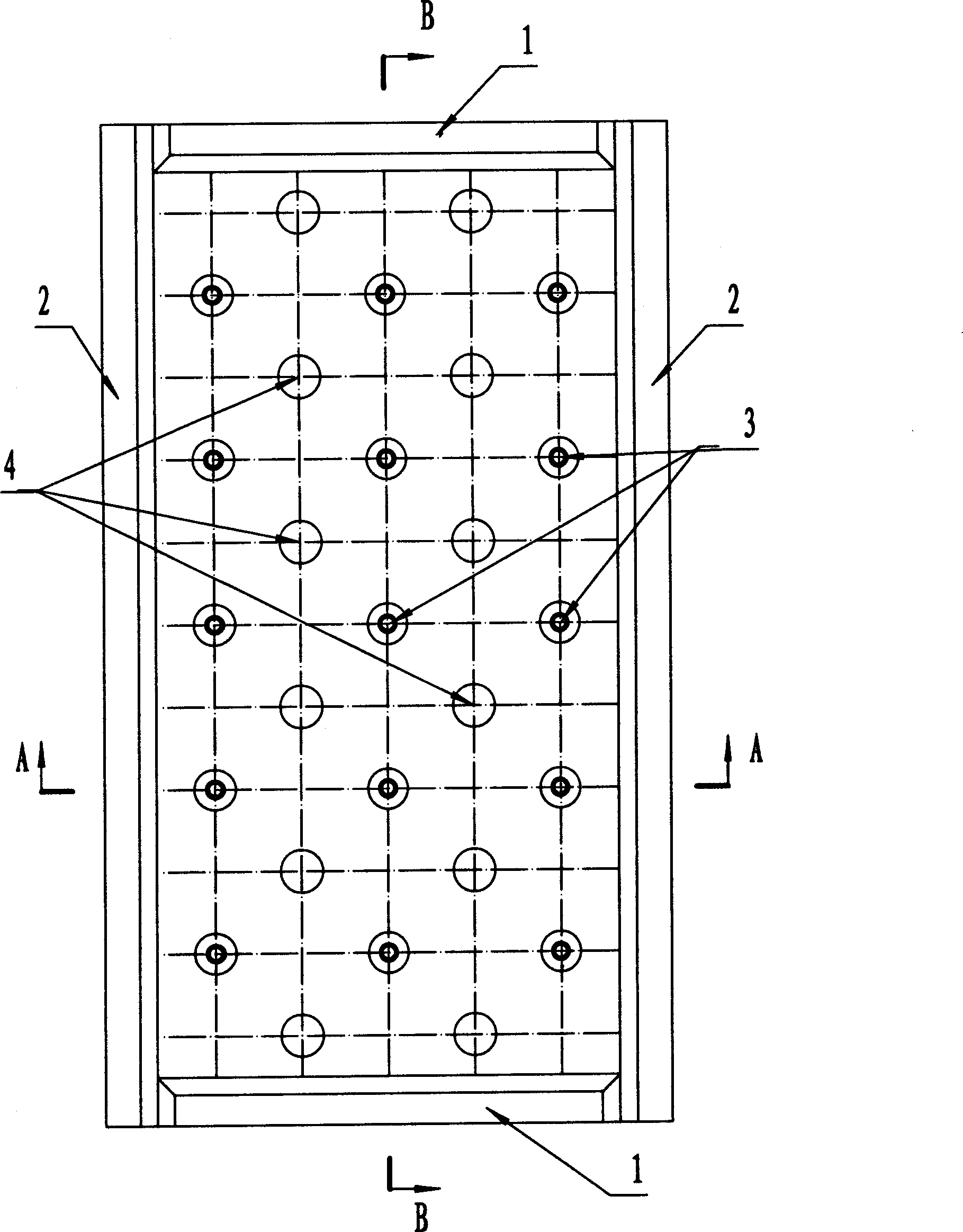

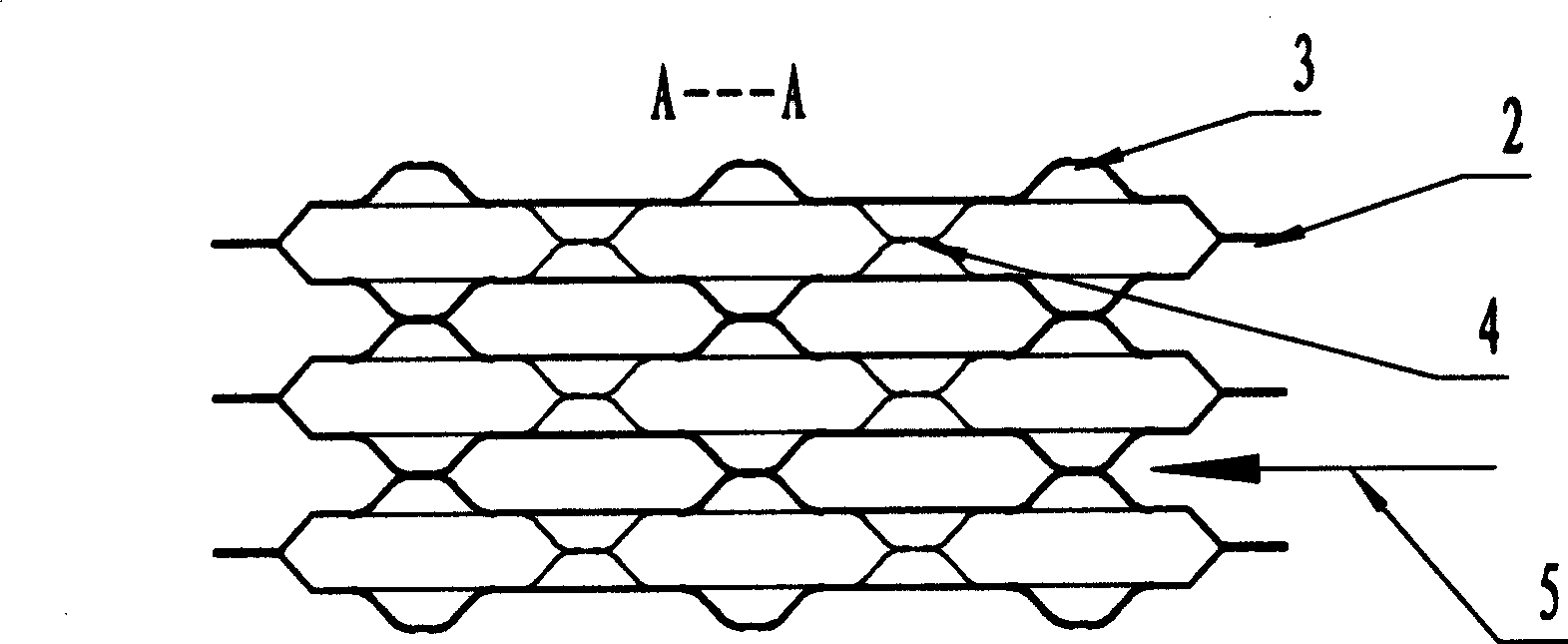

[0016] Example 1, such as figure 1 A dot-type wide-flow channel full-welded heat exchange plate is shown, and its structure is: on the rectangular plate, taking the line connecting the midpoints of the short sides as the axis of symmetry, flat-top hemispherical protrusions 3 and 3 are distributed in a rectangular array. Low hemispherical pits 4, the center lines of the columns or rows of the protrusions are arranged at intervals with the lines of the centers of the columns or rows of the pits, the short side edge 1 and the long side edge 2 are respectively connected with the raised top surface and the concave The bottom of the pit is even.

Embodiment 2

[0017] Example 2, such as figure 1 A dot-type wide-flow channel full-welded heat exchange plate is shown, and its structure is: on the rectangular plate, taking the line connecting the midpoints of the short sides as the axis of symmetry, flat-top hemispherical protrusions 3 and 3 are distributed in a rectangular array. Low hemispherical pits 4, the center lines of the columns or rows of the protrusions are arranged at intervals with the lines of the centers of the columns or rows of the pits, the short side edge 1 and the long side edge 2 are respectively connected with the raised top surface and the concave The bottom of the pit is even. The top of the flat-top hemispherical protrusion or pit is a horizontal disc with a diameter of 2 to 10 mm, and the bottom of the disc is a partial spherical shell with a radius of 5 to 40 mm. The chamfering radius of the spherical shell and the plate is 5 ~40 mm, the diameter of the plate pressing hole is 10 ~ 80 mm. The distance between ...

Embodiment 3

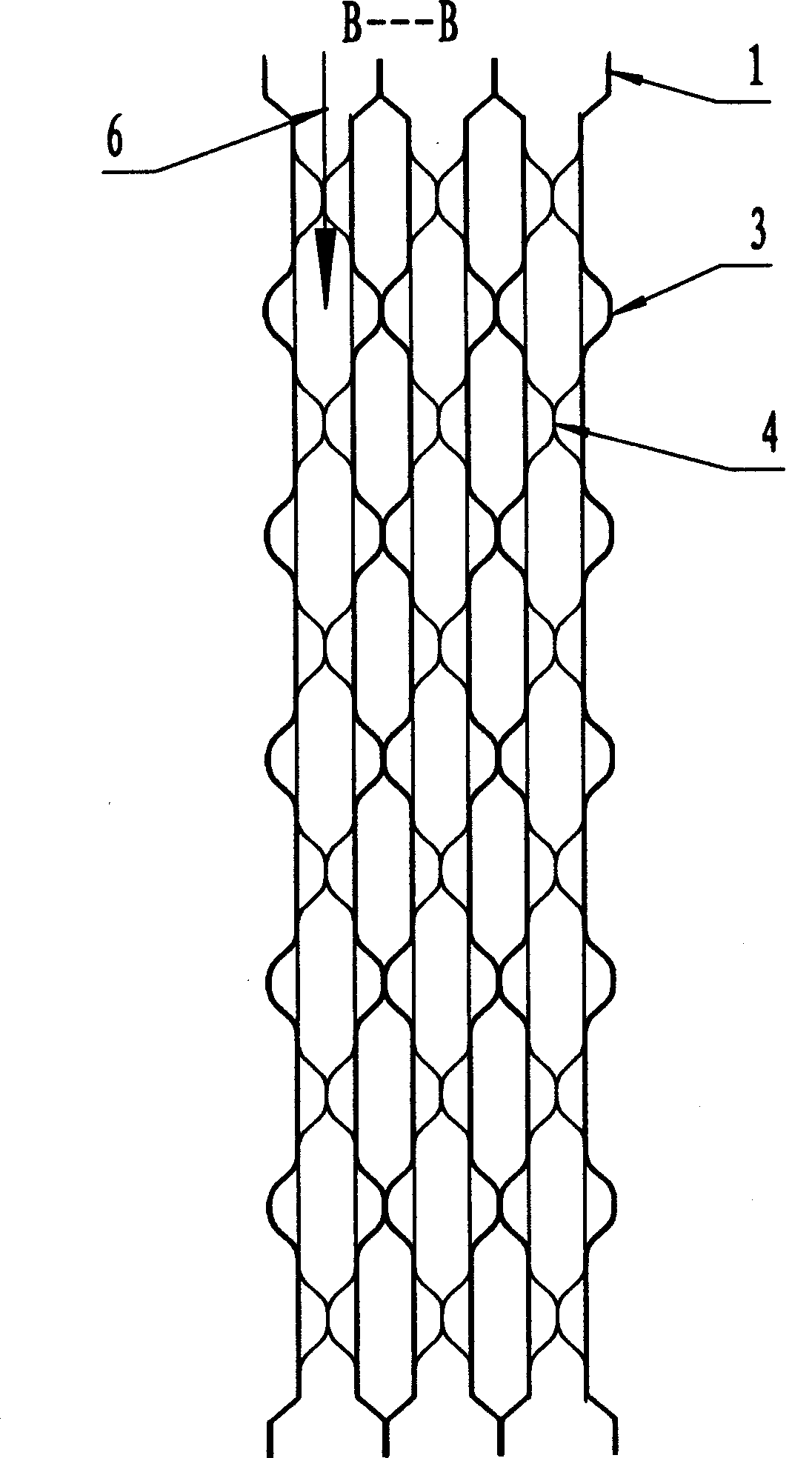

[0018] Example 3, such as image 3 4. As shown in 4, on the plate with a rectangular structure, flat-top hemispherical protrusions 3 and flat-low hemispherical pits 4 are distributed in a rectangular array with the line connecting the midpoints of the short sides as the symmetrical axis. The raised columns or The center line of the row and the center line of the column or row of the pit are arranged at intervals, and the short side edge 1 and the long side edge 2 are respectively flush with the convex top surface and the bottom surface of the pit. The structure of the heat exchanger made of heat exchange plates is: at least three dot-type wide-flow channel fully-welded heat exchange plates are arranged in front and back, and the adjacent short side edges or long side edges are welded together. The inlet and outlet of the primary medium gas flow channel 6 are respectively between the two short sides, and the inlet and outlet of the secondary medium gas flow channel 5 are respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Chamfer radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com