Cotton topping machine

A topping machine and cotton technology, applied in agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of poor cotton height adaptability, difficult application, poor profiling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

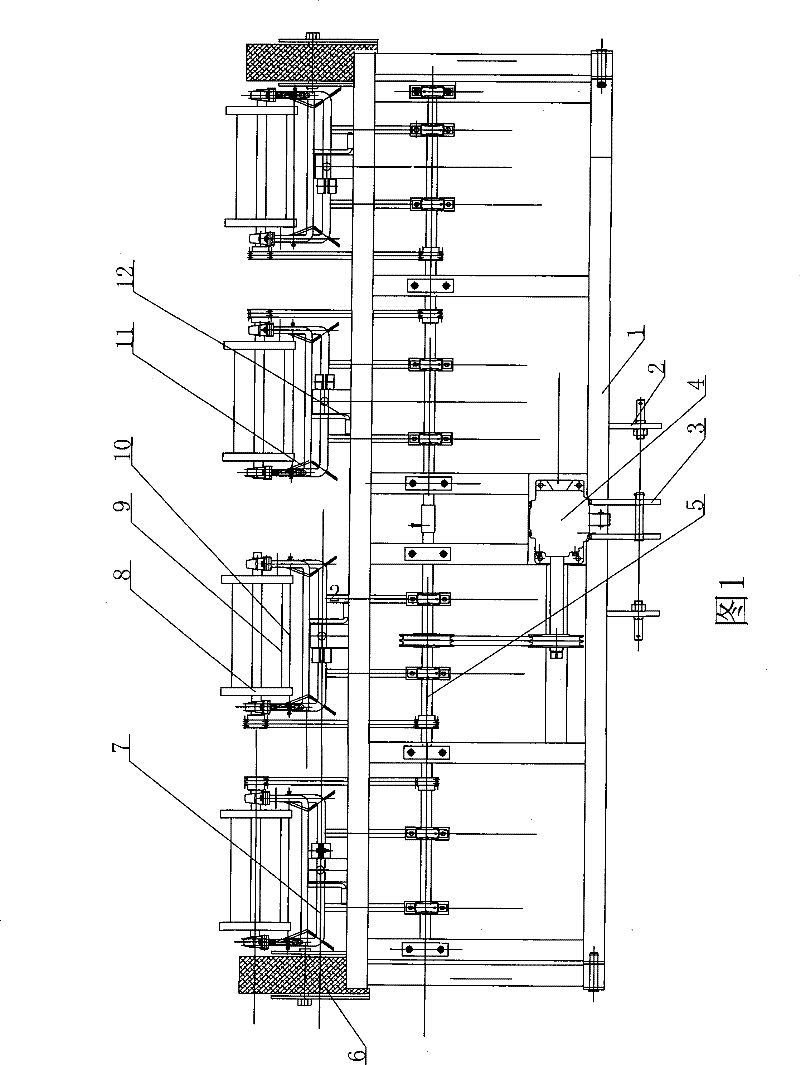

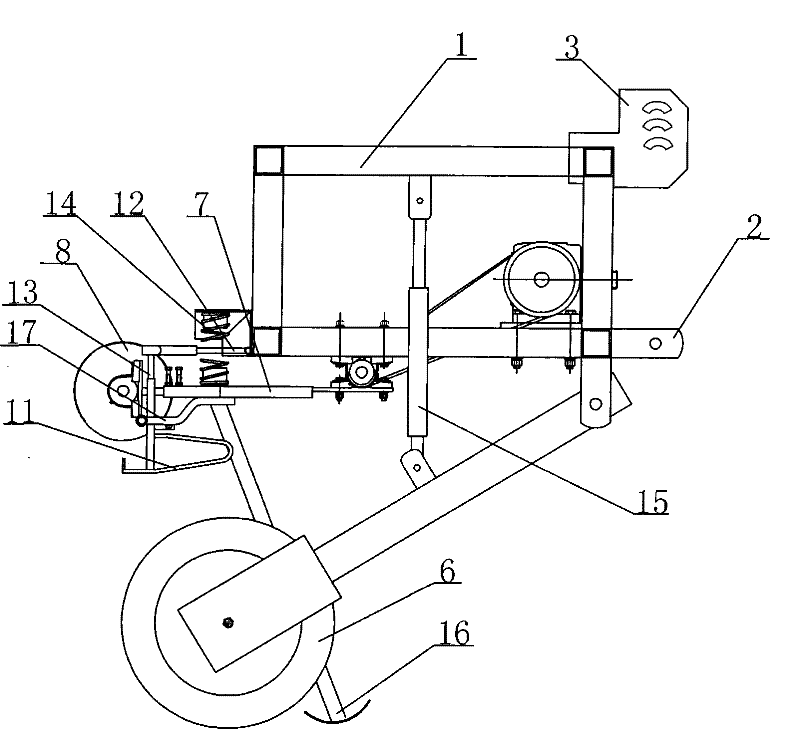

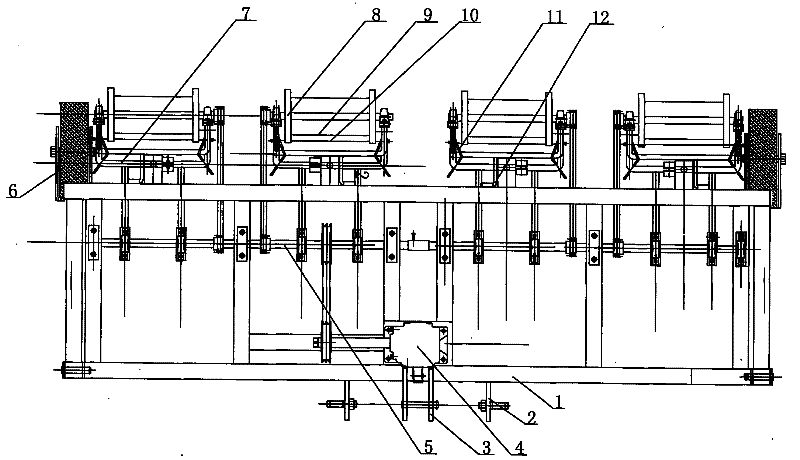

[0012] A cotton topping machine such as figure 1 , figure 2 As shown, it includes a frame with suspension ears, and the frame 1 is a suspension frame with integral hydraulic lifting control, and an upper suspension ear 3 and a lower suspension ear 2 with pin holes are arranged on the rear side of the frame 1, wherein The pin hole of the upper suspension ear 3 is an arc chute hole, and the lower suspension point of the frame 1 is the center. Under the constraint of the upper suspension pin, the height is adjusted along the track of the upper suspension ear 3 arc chute hole. Both sides of the lower part of the frame 1 are respectively hinged with profiling ground wheels 6 with supporting arms, and the hydraulic cylinder 15 is hinged on the supporting arms. The lower part of the floating frame 7, the front end of which is equipped with a moving cutter head 8 with a uniformly distributed steel wire cutting tool through the bearing seat, the tractor transmits the power to the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com