Copper aluminum welding method

A copper-aluminum and aluminum sheet technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of high cost and complex technology, and achieve the effect of convenient welding, uniform connection and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

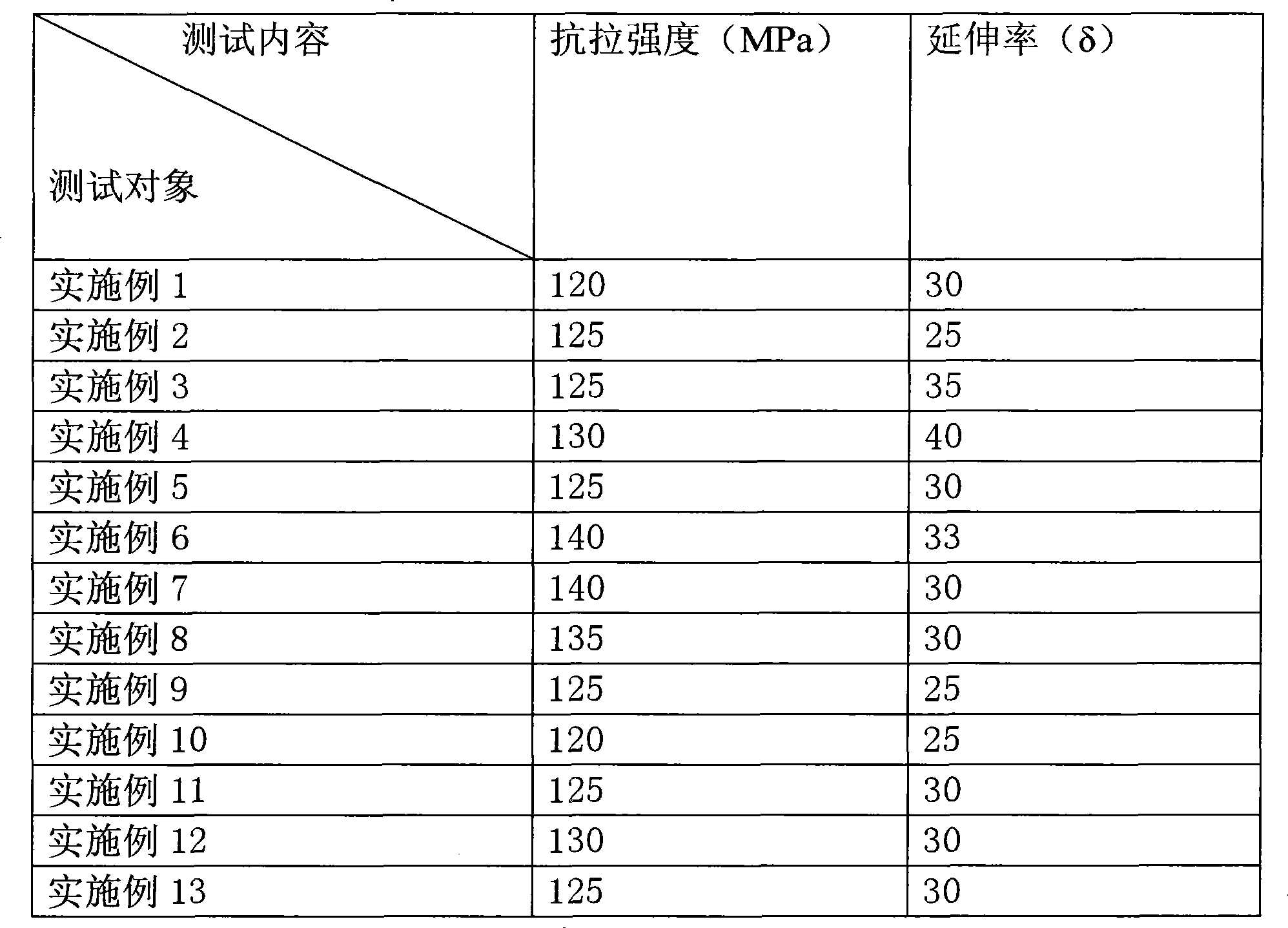

Examples

Embodiment 1

[0019] Select an aluminum sheet with a thickness of 1mm and a copper sheet with a thickness of 1mm for welding, adjust the temperature of welding clamp A to 400°C by electric heating, adjust the temperature of welding clamp B to 700°C by electric heating, and weld Clamp A is in contact with the aluminum sheet, and welding tongs B is in contact with the copper sheet. Immediately after contact, push the welding tongs A and B to superimpose the aluminum sheet and the copper sheet. After the aluminum sheet and the copper sheet are in contact for 3 seconds, remove the welding tongs A With welding pliers B, the copper sheet and the aluminum sheet are firmly welded together.

Embodiment 2

[0021] Select an aluminum sheet with a thickness of 3mm and a copper sheet with a thickness of 5mm for welding. Adjust the temperature of welding tongs A to 450°C and the temperature of welding tongs B to 750°C. After the contact, immediately push welding pliers A and welding pliers B to superimpose the aluminum sheet and copper sheet. After the aluminum sheet is in contact with the copper sheet for 4 seconds, remove the welding pliers A and welding pliers B. The copper sheet and the aluminum sheet are firmly connected. welded together.

Embodiment 3

[0023] Select an aluminum sheet with a thickness of 7mm and a copper sheet with a thickness of 8mm for welding. Adjust the temperature of welding tongs A to 500°C and the temperature of welding tongs B to 800°C. After contact, immediately push welding pliers A and welding pliers B to superimpose the aluminum sheet and copper sheet. After the aluminum sheet and copper sheet are in contact for 5 seconds, remove welding pliers A and welding pliers B. The copper sheet and aluminum sheet are firmly connected. welded together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com