Whole dismounting and whole mounting integral slippage large formwork for thin wall U-shaped beam

A technology of overall slippage and large template, applied in the direction of molds, ceramic forming cores, mold separation devices, etc., to achieve the effect of reducing manual workload, improving the utilization rate of pedestals, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the drawings and specific embodiments.

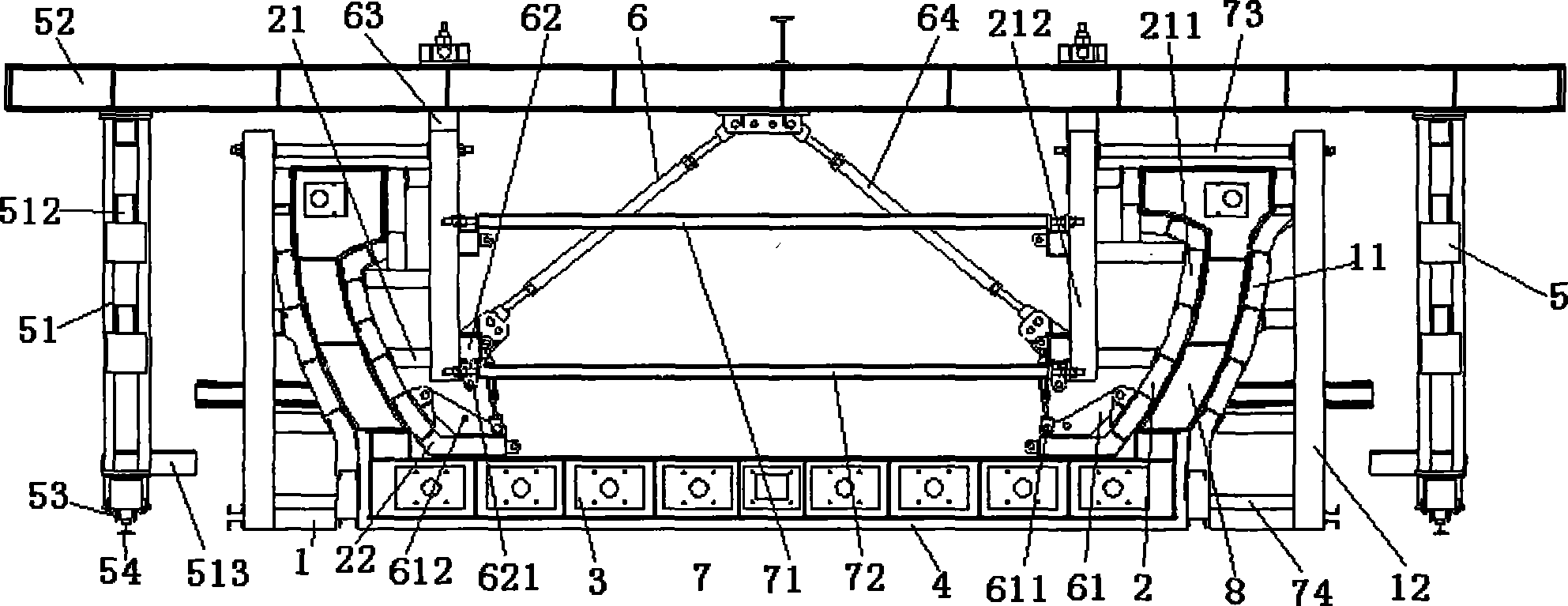

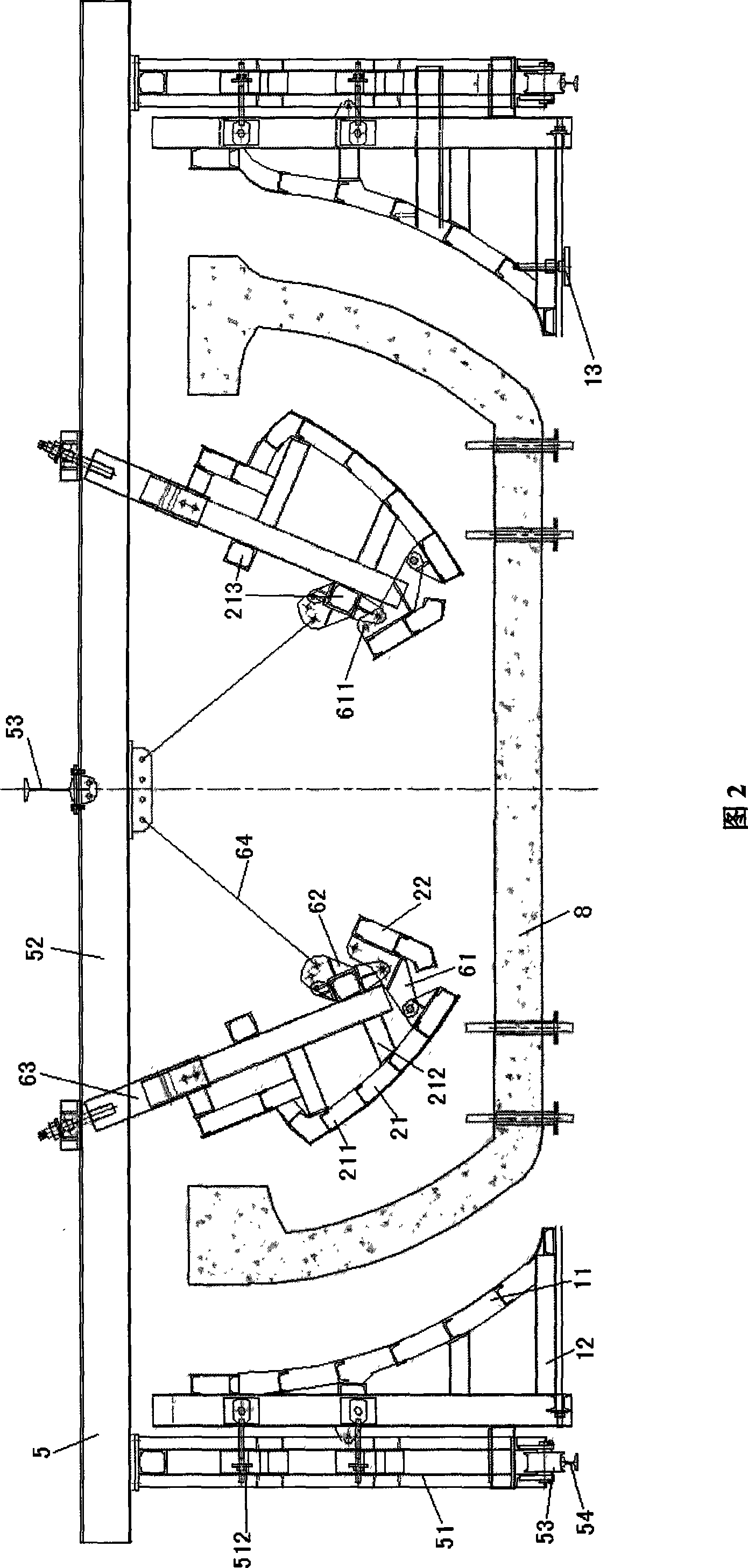

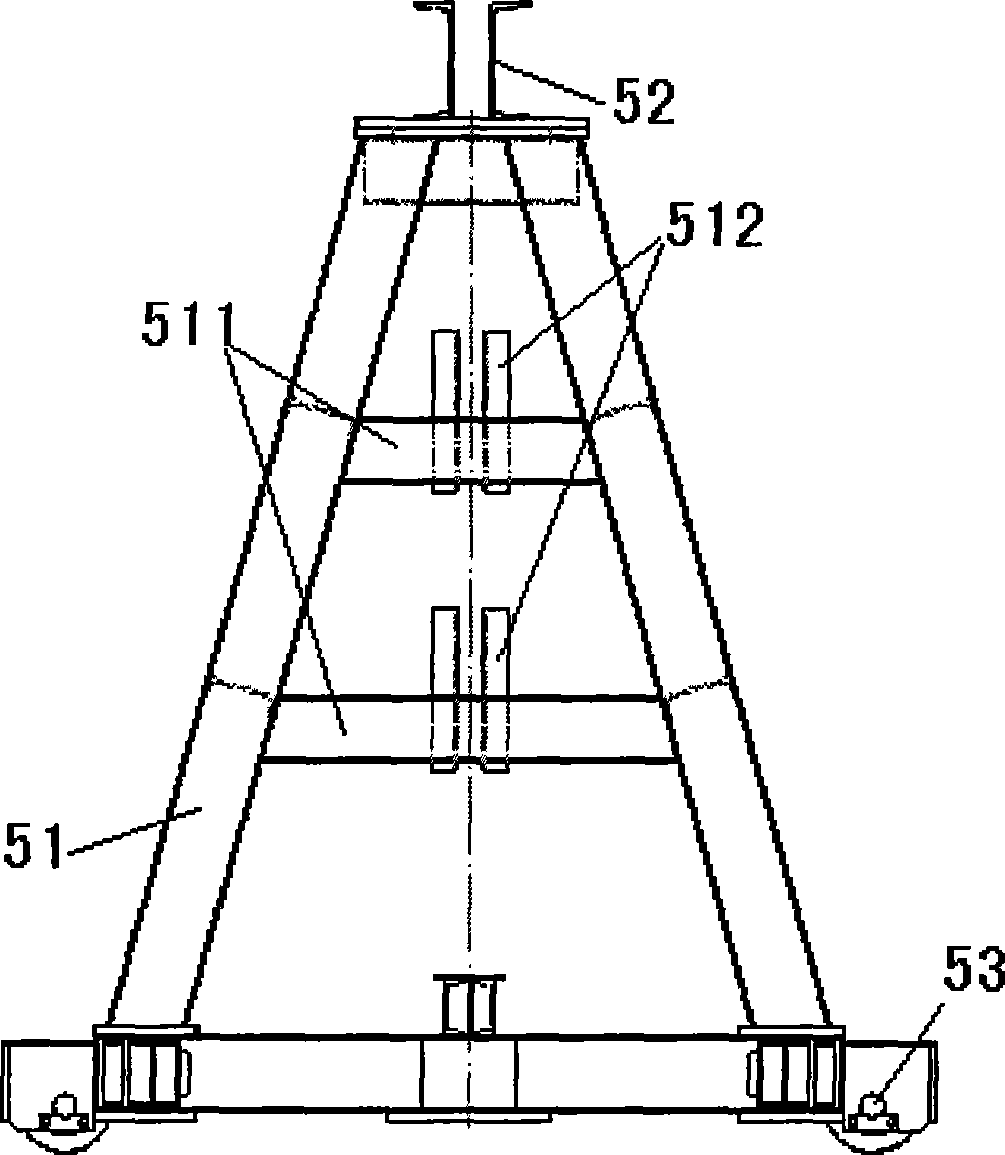

[0027] Such as figure 1 As shown in 2, the thin-walled U-shaped beam of the present invention is completely dismantled and assembled as an integral sliding large template, including the outer mold 1, the inner mold 2, the end mold 3, the bottom mold 4, the gantry 5, the rotation adjustment mechanism 6 and the support mechanism 7;

[0028] The inner mold 2 is arranged on the left and right sides inside the mold, and includes an upper inner mold main body section 21 and a lower flap 22; the inner mold main body section 21 includes an arc-shaped inner mold plate 211 and is arranged behind the inner mold plate at intervals The inner mold sizing skeleton 212 is rotatably connected with the inner template 211, and the inner mold sizing skeleton 212 is connected to form a rigid whole through a long inner connecting rod 213;

[0029] The outer mold 1 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com