Nitrocarburizing method of martensitic stainless steel and preparation method thereof

A martensitic stainless steel, nitrocarburizing technology, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problem of difficulty in ensuring the safety of aircraft, and achieve improved safety and superior technical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now take the nitrocarburizing heat treatment of 2Cr13 martensitic stainless steel (the thickness of the part is 10mm) as an example to describe the present invention in detail.

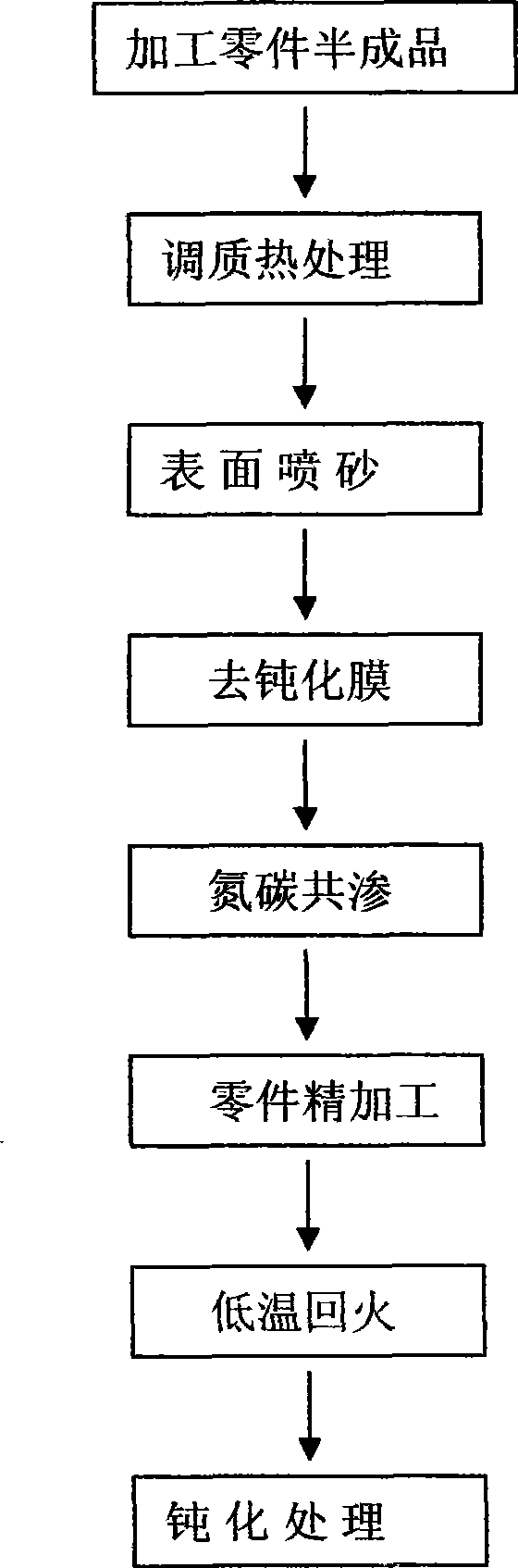

[0025] The martensitic stainless steel material is rough-machined into semi-finished parts, leaving a finishing allowance. then follow figure 1 The steps shown are processed:

[0026] 1. Quenching and tempering heat treatment

[0027] Quenching and tempering treatment of semi-finished parts, keeping (10+2 minutes / mm parts thickness) at 1030°C for 30 minutes during quenching, oil cooling; high temperature tempering at 620°C (60+1 minutes / mm Thickness of parts) heat preservation for 70 minutes, water cooling; check the hardness HRC24-28, check the core structure according to HB5022-94.

[0028] The above-mentioned quenching and tempering treatment can also be carried out after blanking, and the raw materials of the parts are quenched and tempered and then roughly processed into semi-finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com