Construction method for cutting and breaking reinforced concrete pile, column or ground beam

A construction method and reinforced concrete technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as failure to meet construction period requirements, high labor intensity, industrial accidents, etc., achieve considerable construction period benefits, improve work efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments:

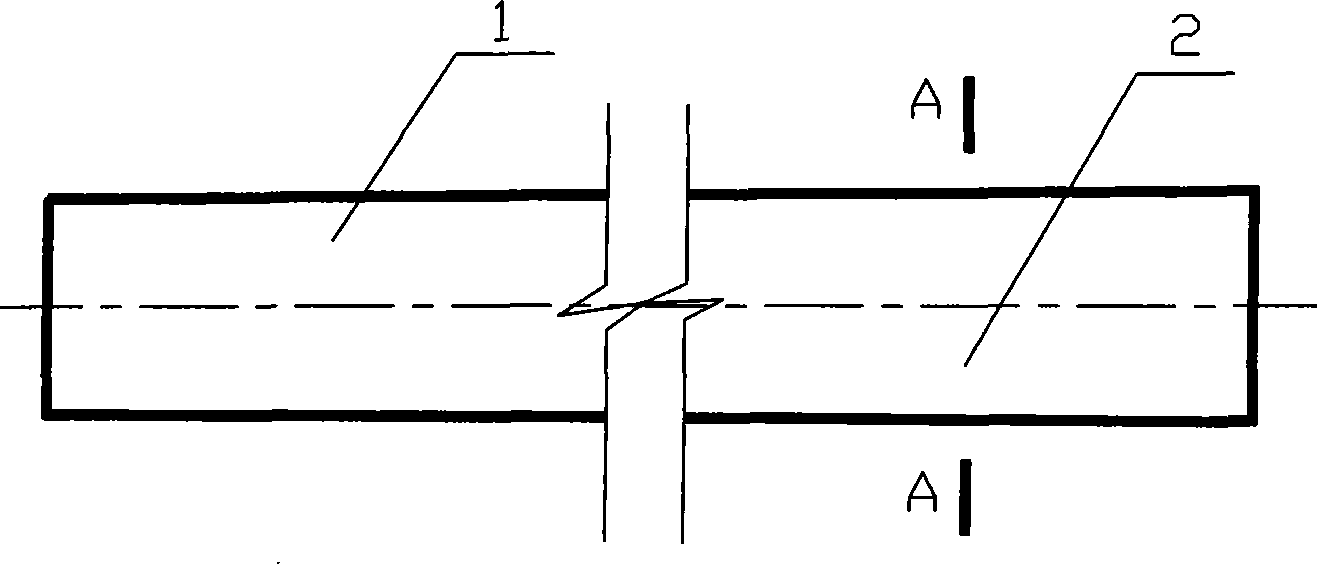

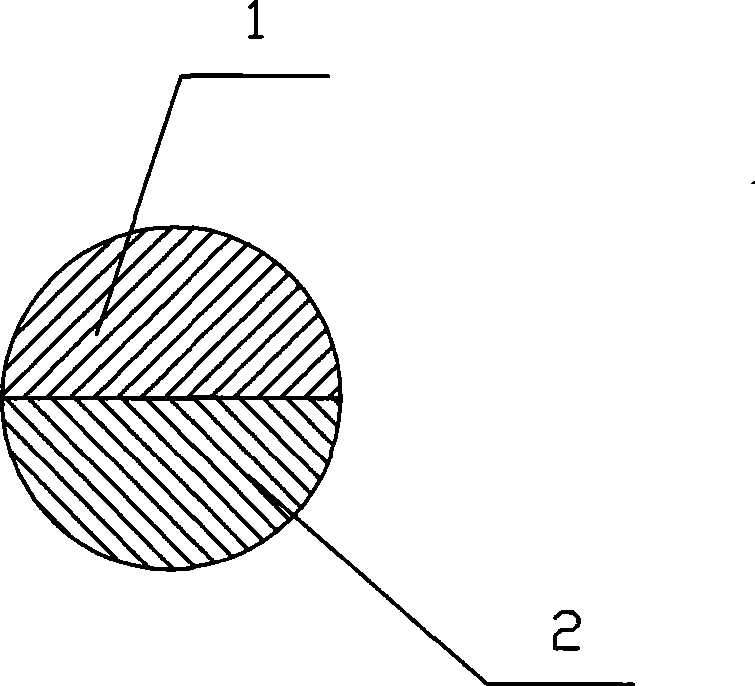

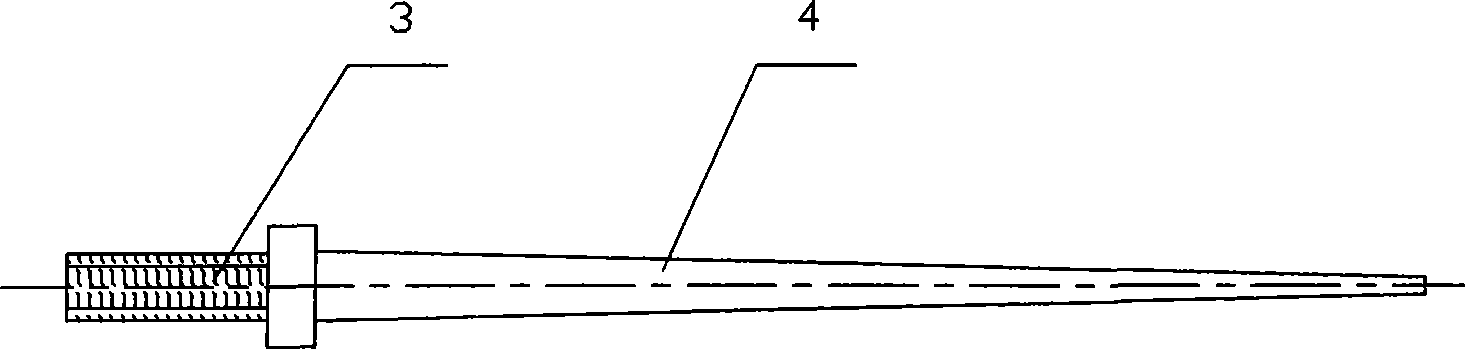

[0020] See Figure 1 to Figure 4 , The present invention is a construction method for truncated and broken reinforced concrete piles, including the following steps:

[0021] (1) Use a level, tower ruler, and steel ruler to measure the elevation of the pile that needs to be cut and broken, and mark the obvious cut position mark on the pile;

[0022] (2) Remove the concrete protective layer above the cutoff position, and peel off the main reinforcement; after removing the protective layer, the main reinforcement must not be excessively bent or cut at will;

[0023] (3) Generally, one deep hole is required as a crack hole when drilling a pile; two shallow holes are used as fracture guide holes. Drill horizontally at the cut-off position of the pile body. The depth of the expansion hole can be one-half to three-quarters of the pile diameter. If the pile head to be cut is hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com