Radially staged microscale turbomolecular pump

A turbomolecular and rotor technology, applied in the design and manufacture of small turbomolecular vacuum pumps, can solve problems such as difficult pumping volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

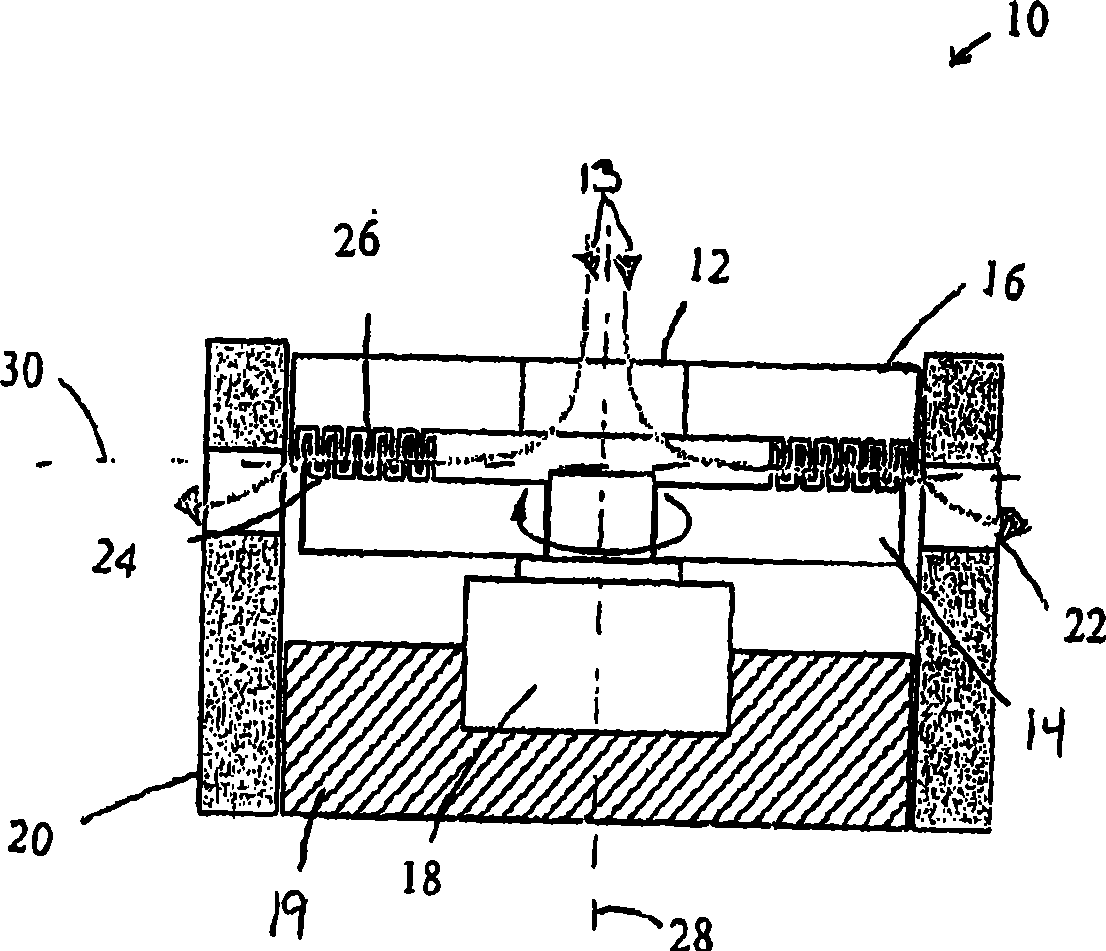

[0015] figure 1 An example diagram of a turbomolecular pump 10 showing radial flow. The pump 10 includes an inlet 12 , a rotor 14 , a stator 16 , a motor 18 , a housing 20 and a plurality of outlets 22 . The rotor 14 includes a plurality of rotor blades 24 . The stator 16 includes a plurality of stator slots 26 .

[0016] Housing 20 surrounds rotor 14 and stator 16 . Motor mount 19 holds motor 18 in place and aligns motor 18 with rotor 14 and stator 16 . The inlet 12 is used to allow a quantity of gas 13 to enter the housing 20 and flow into the rotor 14 .

[0017] Each slot of the plurality of stator slots 26 is positioned to receive each blade of the plurality of rotor blades 24 . In the assembled state, the stator 16 is fixed and the rotor 14 is free to rotate.

[0018] The peripheral speed of the rotor can be from 10 to 300m / s, depending on the required compression ratio and air flow. Rotation of the rotor 14 relative to the stator 16 causes gas to be pumped radiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com