Wide-band antireflective film and optical element with the wide-band antireflective film

An anti-reflection film and optical element technology, applied in optical elements, optics, instruments, etc., can solve the problems of adverse effects on optical performance of optical elements, slight changes in color tone, and poor anti-reflection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings.

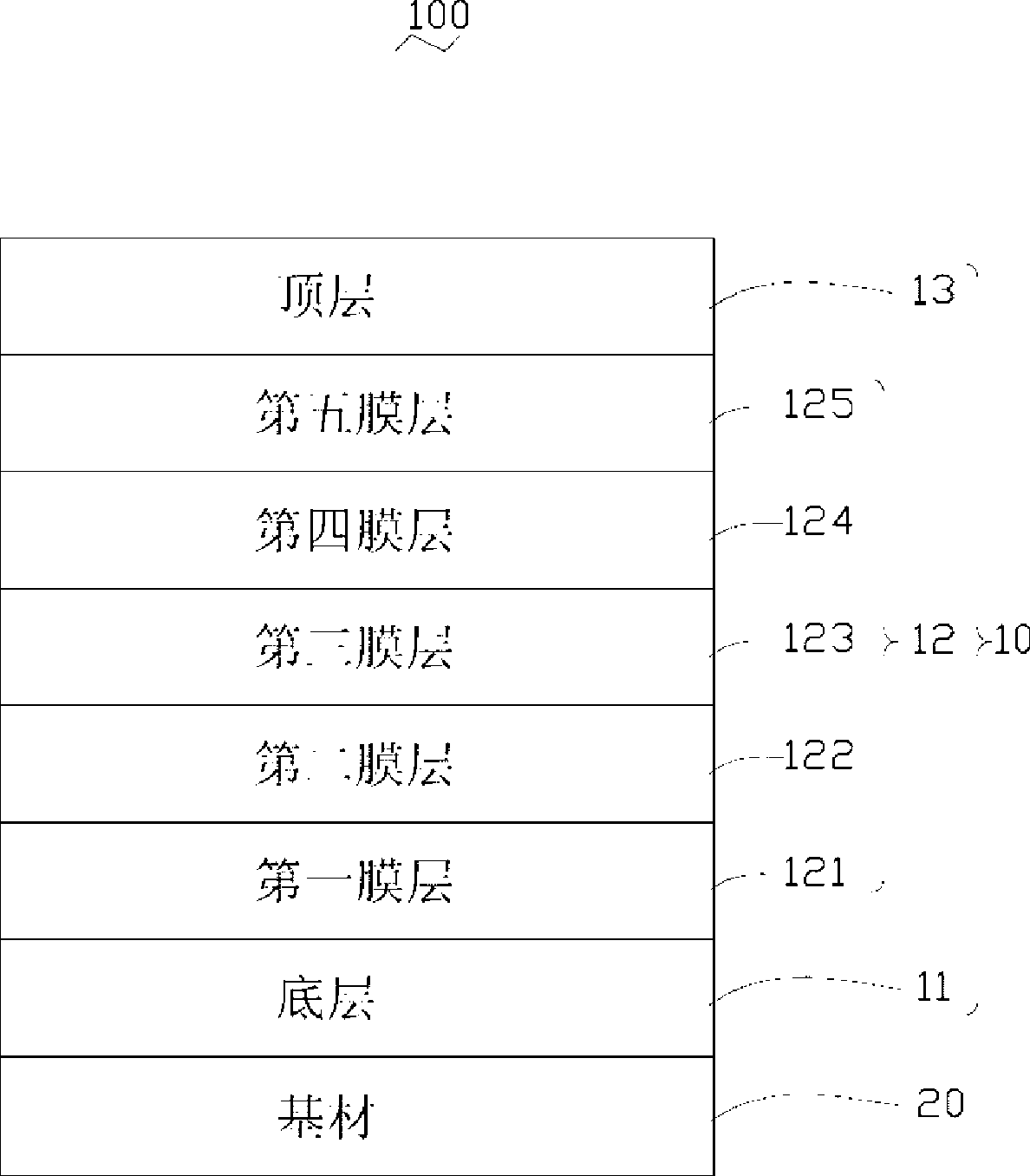

[0011] see figure 1 , is an optical element 100 provided by an embodiment of the present invention, and the optical element 100 includes a substrate 20 and a broadband anti-reflection film 10 formed on one surface of the substrate 20 . The optical element 100 may specifically be an optical element such as a lens or a prism.

[0012] The material of the substrate 20 can be glass or plastic. It can be understood that a broadband anti-reflection film 10 can be formed on each surface of the substrate 20 for light to pass through, such as a lens, which can form a broadband anti-reflection film 10 on both surfaces to improve the lens light transmittance.

[0013] The broadband anti-reflection film 10 includes a bottom layer 11 , a widening layer 12 and a top layer 13 sequentially formed along the surface of the substrate 20 .

[0014] The bottom layer 11 is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com