Interposing frame and retaining plate component, and communication equipment

A technology of baffles and frame inserts, which is applied in the field of baffle components, can solve the problems of airflow short circuit, low heat dissipation effect of circuit boards, airflow loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

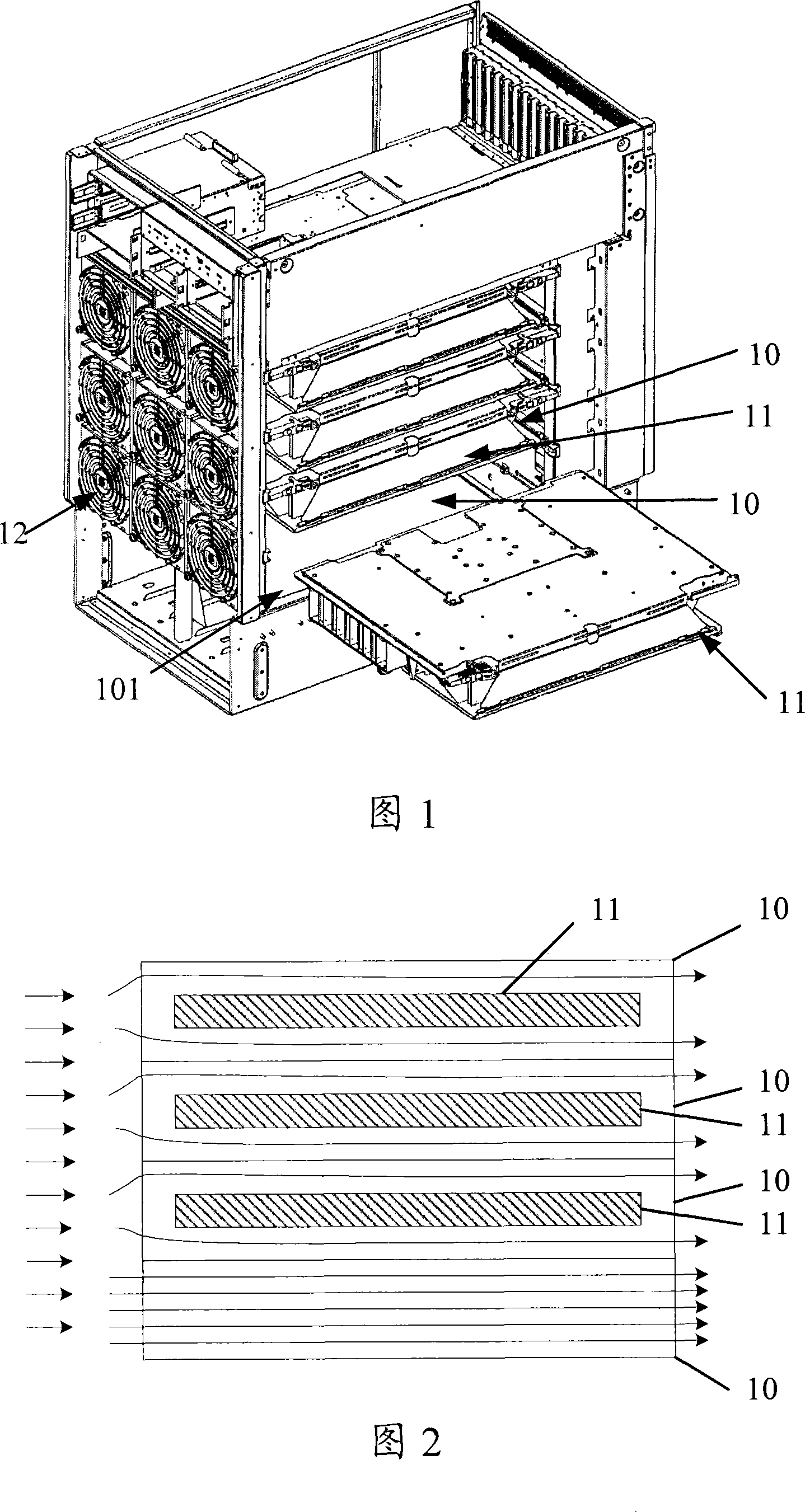

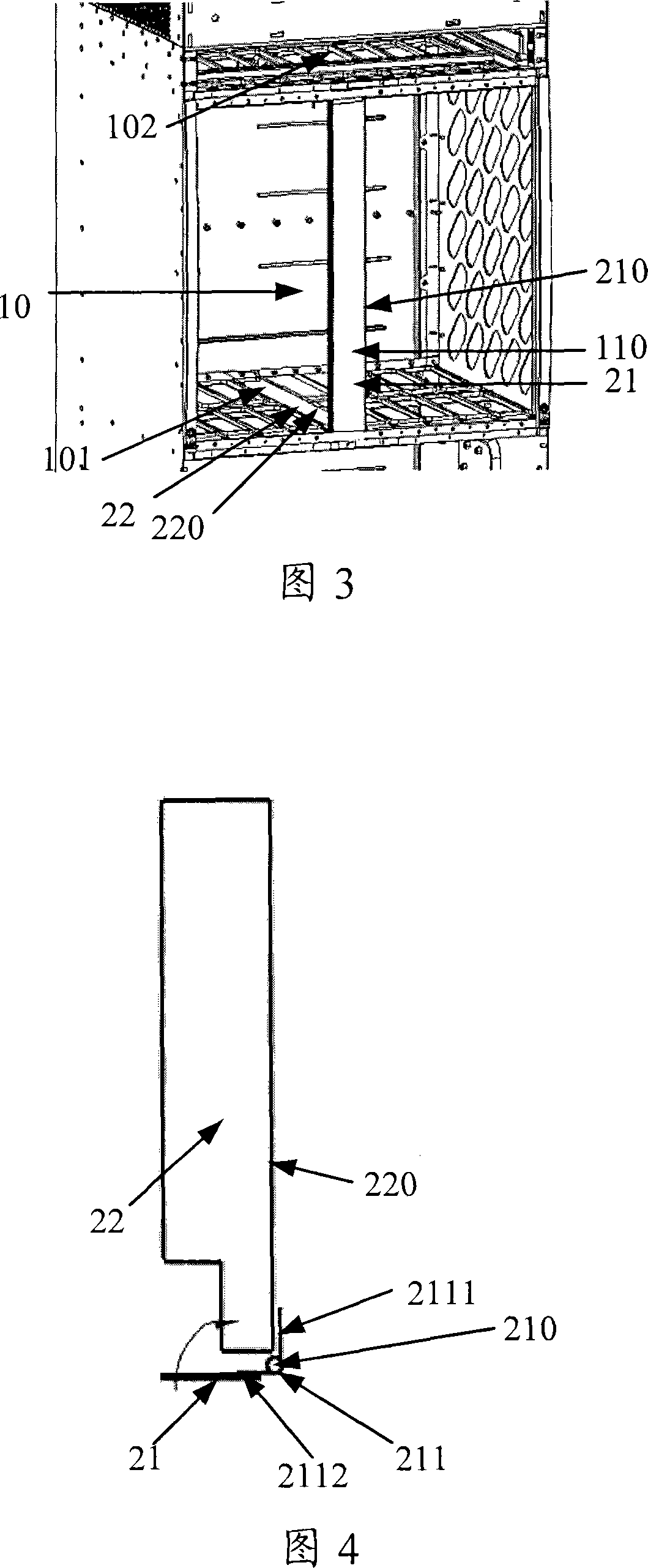

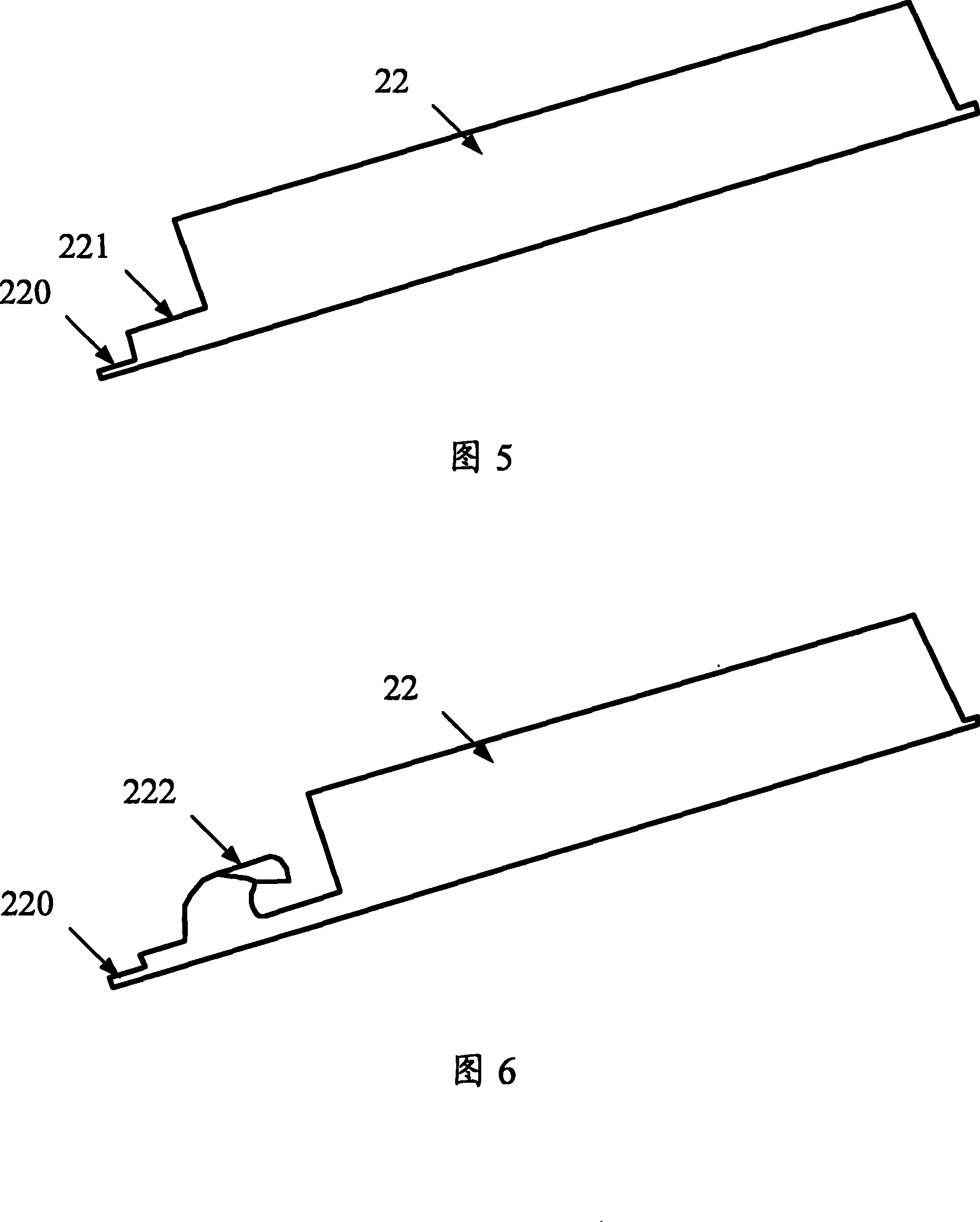

[0040] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments.

[0041] In the embodiment of the present invention, a baffle plate assembly is provided in the slot of the insert frame, and the baffle plate assembly includes two baffle plates, one of the baffle plates has a rotating shaft, and the rotating shaft is located on one side of the plane where the insertion port is located. It can rotate around its axis of rotation between a preset first position and a second position, wherein if the baffle is in the first position, its projected area in the direction in which the circuit board is inserted into the slot is greater than or equal to the area of the insertion port, If it is in the second position, it will not interfere with the circuit board inserted into the slot; the other baffle in the baffle assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com