Radiation curable system

A technology of radiation curing and radiation polymerization, applied in chemical instruments and methods, paper/cardboard layered products, layered products, etc., can solve problems such as chemical limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

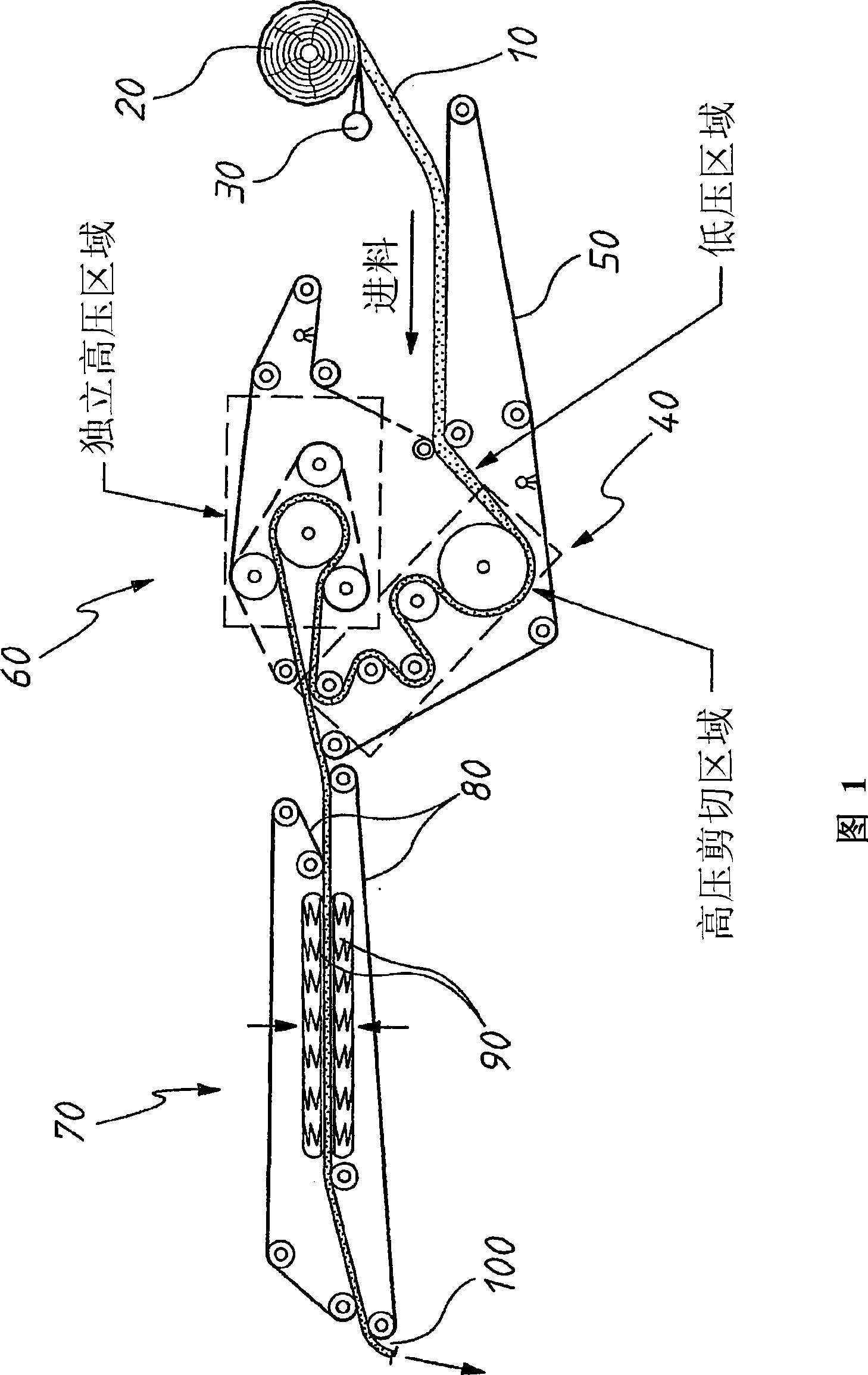

Image

Examples

Embodiment Construction

[0124] In this invention it is shown how the problems of the prior art can be overcome by using a new series of novel monomer and oligomer systems which can contain low percentages of water. More importantly, these new systems (compositions) are water compatible, thereby enabling coating handling, especially in-line washing, to be accomplished with aqueous materials. The composition may be a radiation curable water compatible composition which is radiation curable without reducing the water content of the composition prior to curing. The system can be water-dispersible, water-soluble, water-emulsifiable, can form microemulsions in water, or can be water-compatible in some other way. They can be high solids systems. They may have a solids content of at least about 60%, or at least about any of the following percentages: 65, 70, 75, 80, 85, 90, or 95%, or one of the following ranges: about 55 to about 100% , about 60 to about 100%, about 70 to 100, 80 to 100, 90 to 100, 95 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com