Objectif photographique en 3d

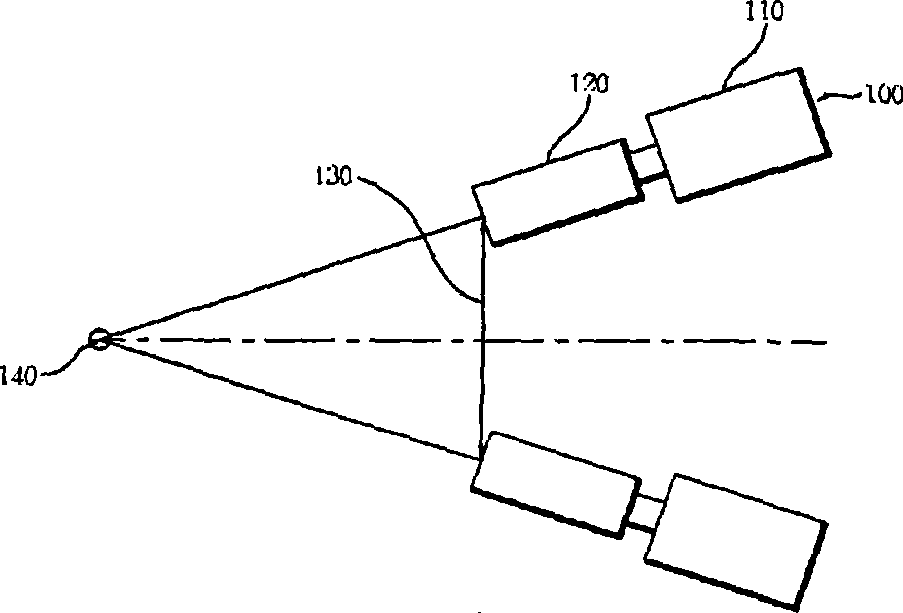

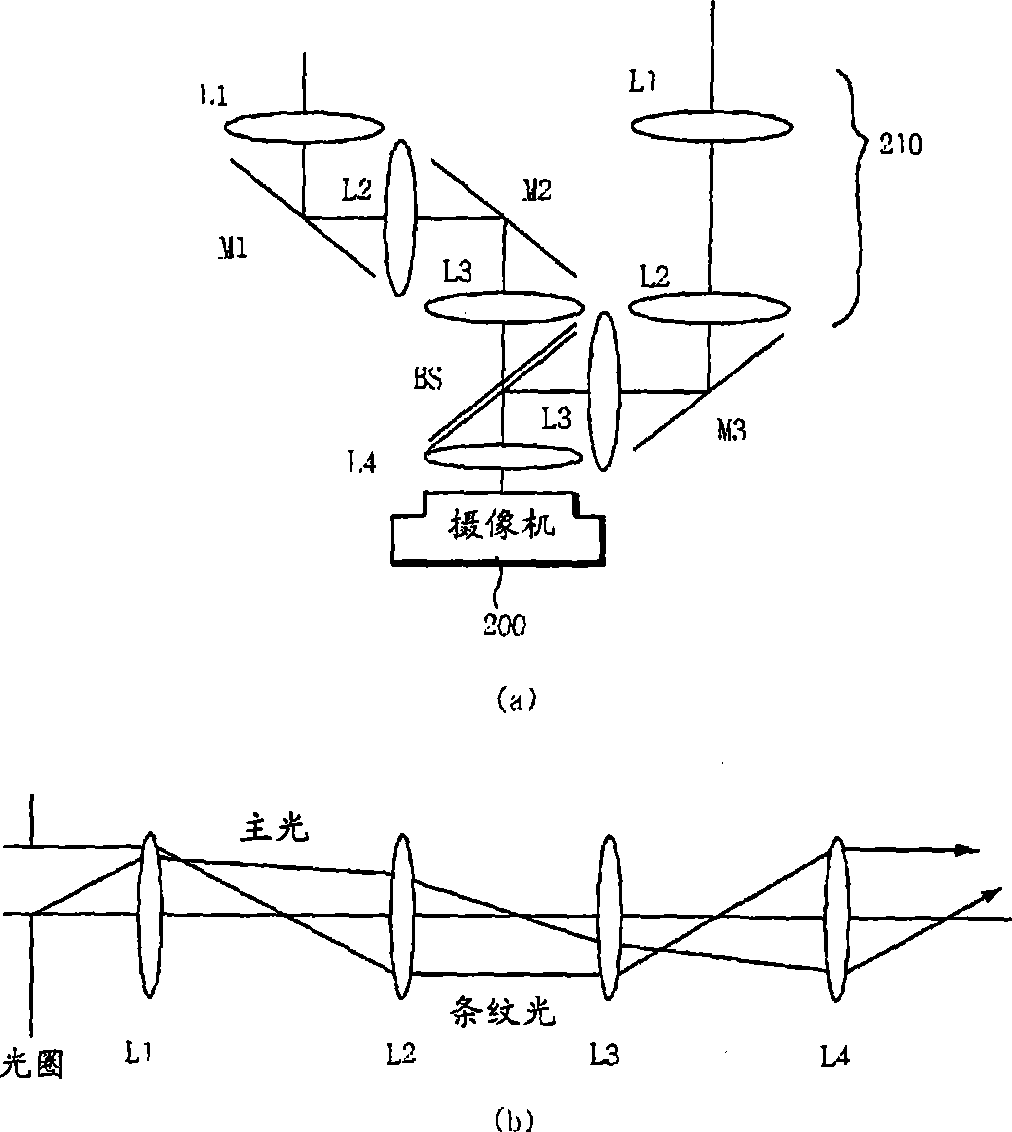

A lens system and three-dimensional camera technology, applied in stereoscopic systems, image communications, instruments, etc., can solve problems such as difficulty in maintaining equal distances, difficulty in uniformly operating zoom lenses and focus lenses, and difficulty in attaching, etc., to achieve Realize the effect of lens replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

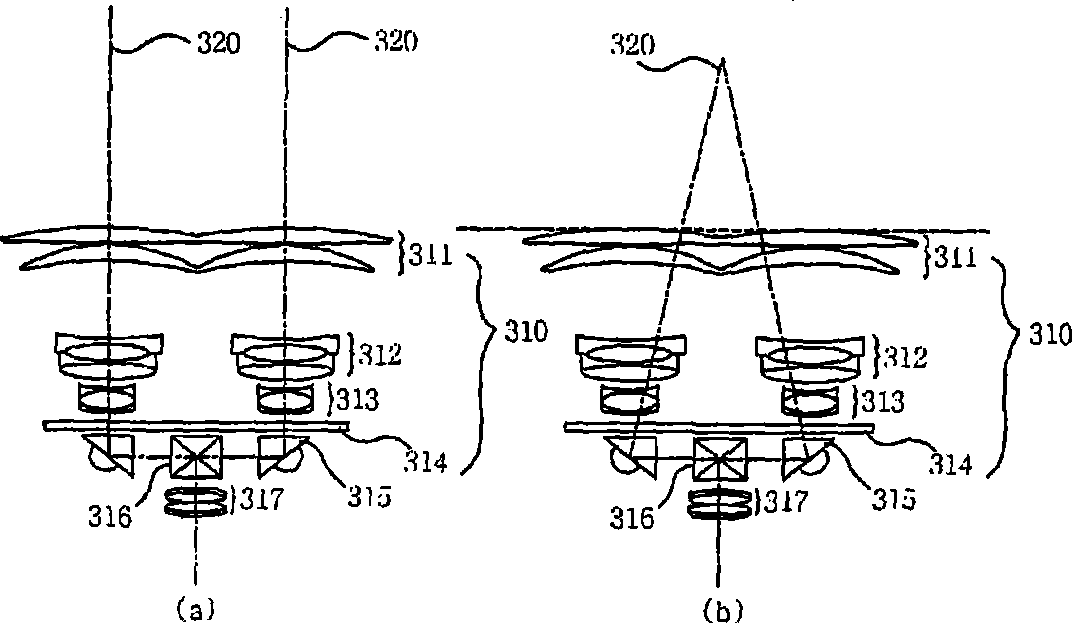

[0087] Figure 7 The galvanometer provided in place of the rotating disk of the light transmissor / reflector according to the first embodiment of the present invention is shown. Refer to Figure 7 , The two front lenses 410 on the left and right sides maintain a binocular distance of 65 mm and are arranged in the front, so that the image is formed in the space behind the front lens 410. The first relay lens 420 is used to convert the image into parallel light. At the same time, total reflection mirrors 431-1 and 431-2 are used to synthesize images by galvanometer 433, in which two mirrors 433-1 and 433-2 are joined at 50°. Therefore, an image is formed on the CCD 480 via the second relay lens 460.

[0088] Specifically, for the light reflection operation, in the galvanometer 433 configured so that the mirrors 433-1 and 433-2 are formed on both sides at 50°, the light initially incident from the left side is passed by the total reflection mirror 431- 1 reflects and thus refracts 90°...

no. 2 approach

[0092] Figure 8 The galvanometer provided in place of the rotating disk 432 of the light transmissor / reflector 430 according to the second embodiment of the present invention is illustrated. Refer to Figure 8 , The two front lenses 410 maintain a binocular distance of 65 mm, and light is incident through the two front lenses 410 to form an image in the space behind the front lens 410. The first relay lens 420 is used to transform the image into parallel light. At the same time, total reflection mirrors 431-1 and 431-2 are used, thereby synthesizing images by the galvanometer 434 to which the reflection mirror 434-1 is attached. Therefore, the image is formed on the CCD via the second relay lens 460.

[0093] Specifically, for the light reflection operation of the galvanometer 434 constituted by the reflecting mirror 434-1, the light initially incident from the left is reflected by the total reflection mirror 431-1, thereby being deflected by 90° to the right. In this case, if t...

no. 3 approach

[0098] FIG. 9 illustrates a galvanometer provided in place of the rotating disk 432 of the light transmissor / reflector 430 according to the third embodiment of the present invention. 9, the two front lenses 410 maintain a binocular distance of 65 mm, and light is incident through the two front lenses 410 to form an image in the space behind the front lens 410. The first relay lens 420 is used to convert the image into parallel light. At the same time, total reflection mirrors 431-1 and 431-2 are used, thereby synthesizing images by the galvanometer 435 to which the reflection mirror 435-1 is attached. Therefore, the image is formed on the CCD via the second relay lens 460.

[0099] Specifically, for the light reflection operation of the galvanometer 435 constituted by the mirror 435-1, the light initially incident from the left is reflected by the total reflection mirror 431-1 and is thereby deflected to the right. In this case, if the galvanometer 435 rotates clockwise by an angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com