Preparation method of food additive 3,4-dihydroxy-benzoil acid

A technology of hydroxybenzoate and dihydroxybenzoic acid, applied in the field of food additives, can solve problems such as unfavorable industrialized production, complicated operation, non-compliance with the quality requirements of food additives, etc., and achieve the effect of feasible process conditions and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

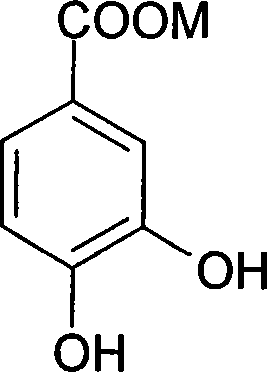

Image

Examples

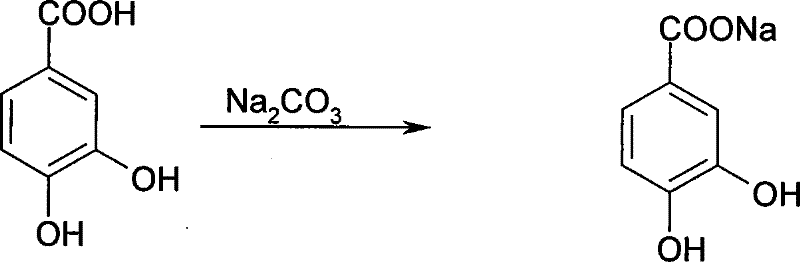

Embodiment 1

[0020] Pretreat the commercially available 3,4-dihydroxybenzoic acid uniformly, take 154g (1 mole), dissolve it in 10-15 times deionized water, add 53-212g (0.5- 2.0 mole) of sodium carbonate, add in about 30 minutes, stir for 2-8 hours, concentrate under reduced pressure until viscous, add 250-800ml of acetone or ethanol, heat up to reflux, then cool to crystallize, filter, and dry to obtain white crystals , yield 95%.

[0021] The present invention can also be realized through the following steps:

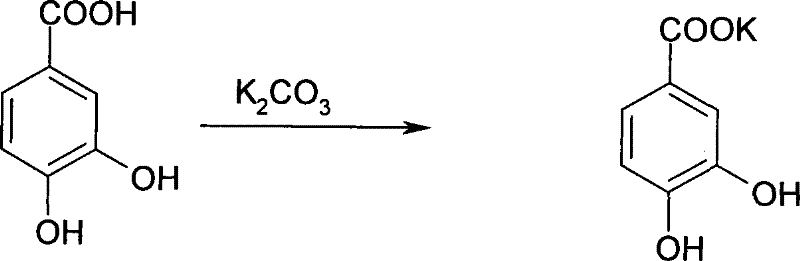

[0022] Dissolve 1 mole of pretreated 3,4-dihydroxybenzoic acid in 10-15 times of deionized water, add 0.5-2.0 mole of potassium carbonate at 0-60°C under stirring, and stir for 2-8 hours after adding , concentrated under reduced pressure to the utmost, add 50-400ml of acetone or ethanol, heat up to reflux, then cool to crystallize, filter, and dry to obtain the product.

[0023] Reaction two:

[0024]

Embodiment 2

[0026] Pretreat the commercially available 3,4-dihydroxybenzoic acid uniformly, take 154g (1 mole), dissolve it in 10-15 times deionized water, add 69-276g (0.5- 2.0 mole) of potassium carbonate, add in about 30 minutes, stir for 2-8 hours, concentrate under reduced pressure to a viscous state, add 250-800ml of acetone or ethanol, heat up to reflux, cool to crystallize, filter, and dry to obtain white crystals , yield 95%.

[0027] In the preparation process of the present invention, the consumption of sodium carbonate or potassium carbonate is the key. If the usage is insufficient, the salt formation of 3,4-dihydroxybenzoic acid will be insufficient, and the raw materials will be entrained in the product. If used in excess, the product will have It is pink and does not meet the requirements for food additives.

[0028] The raw materials of the present invention can be bought in the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com